A Dynamic Calibration Method for Accelerator Pedal Position of Potentiometer

A technology for the position and dynamic calibration of the accelerator pedal, which is applied in the layout of the power unit control mechanism, the measurement device, and the test of the vehicle. The effect of good performance, low compensation accuracy and precise accelerator pedal position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The method of the present invention is illustrated below by specific examples. What this example uses is a six-cylinder heavy truck engine electronic controller, which includes an accelerator pedal control unit to be tested. The implementation steps are as follows:

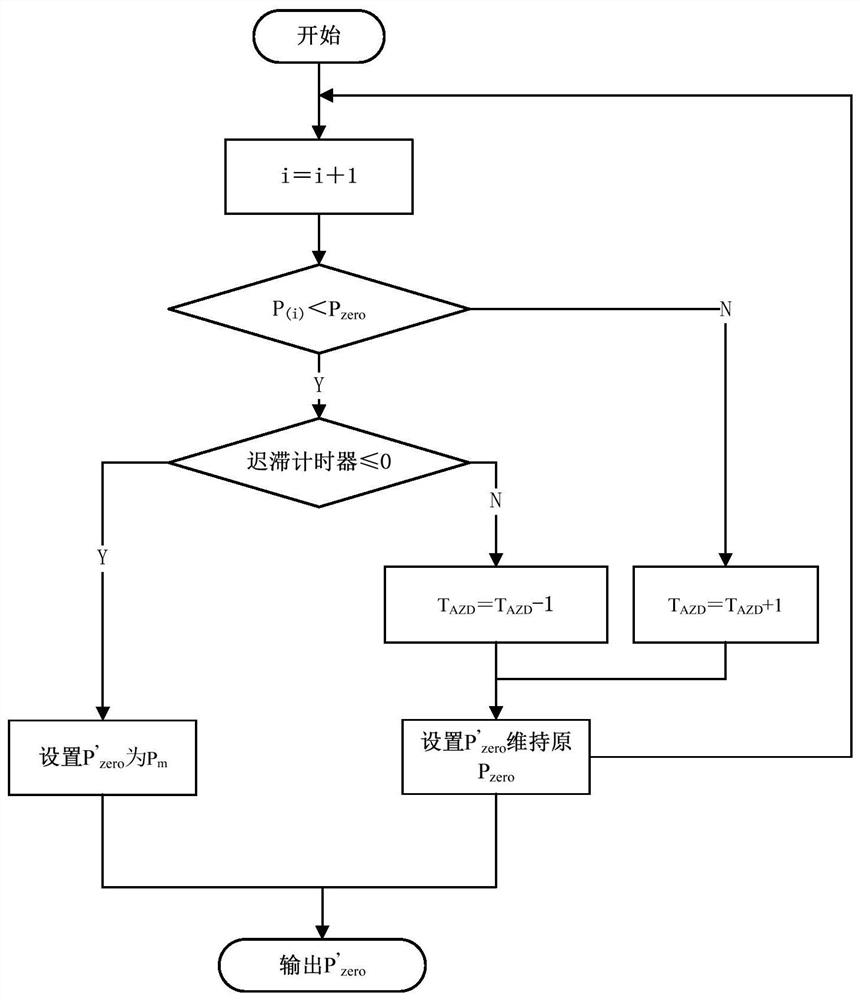

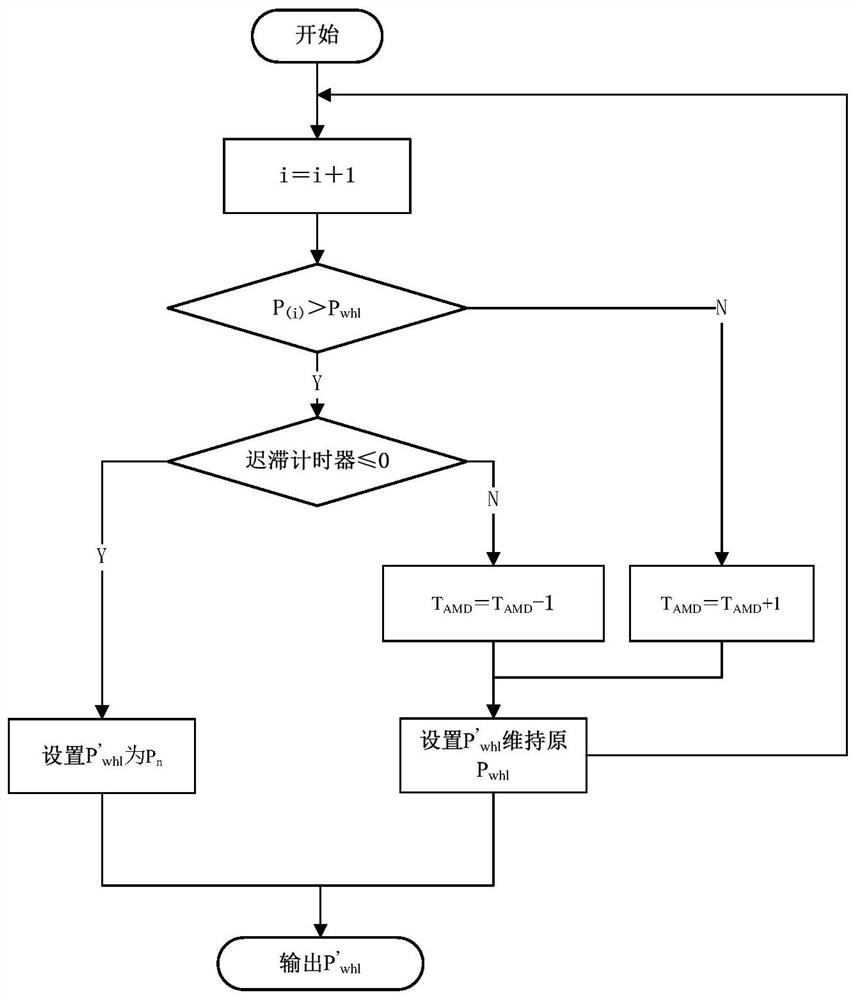

[0026] Step 1: Determine the zero range value T corresponding to the potentiometer when calibrating the throttle zero position according to the characteristics of the potentiometer before installation PZ The full-scale value T corresponding to the potentiometer is 26% and the throttle is full-scale PW is 89%; set the first-order linear filter coefficient C FLTR =0.15; zero calibration delay T AZD 500ms, full scale bit calibration delay T AMD 500ms;

[0027] Step 2: After the car is started, according to the calibrated zero range value T PZ Set current throttle zero position P zero , while according to the calibrated full-scale value T PW Set the current full throttle position P whl ;

[0028] Step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com