An in-orbit 3D printer

A 3D printer and print head technology, applied in 3D object support structures, coating devices, manufacturing tools, etc., can solve problems such as increased launch costs, 3D size limitations, losses, etc., to reduce transportation costs, ensure service life, The effect of good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

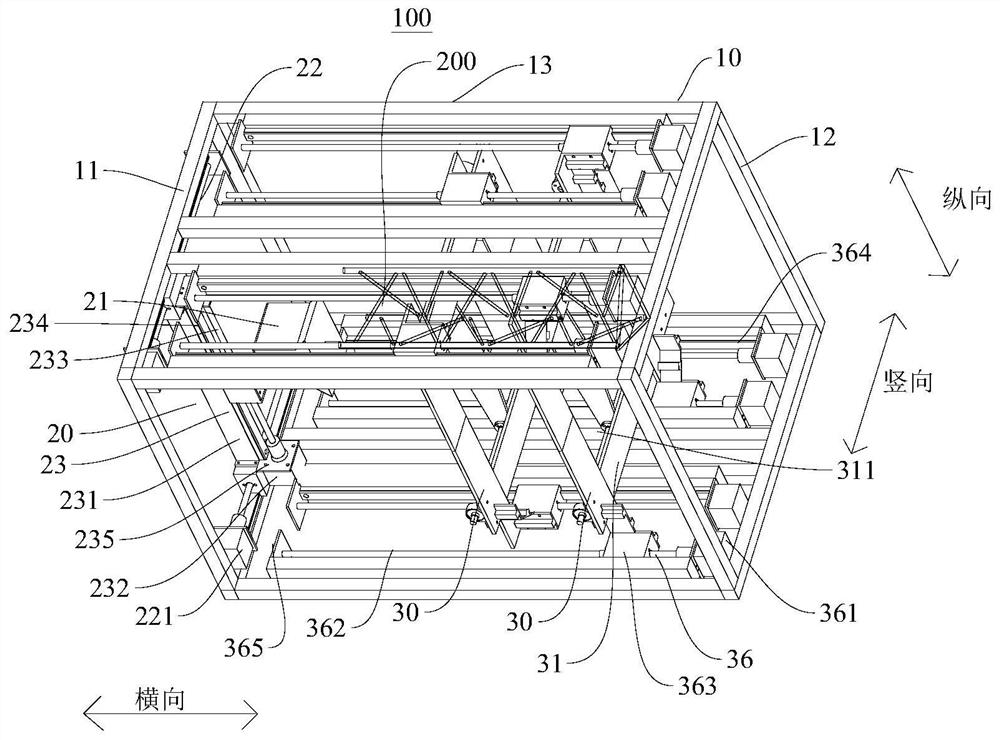

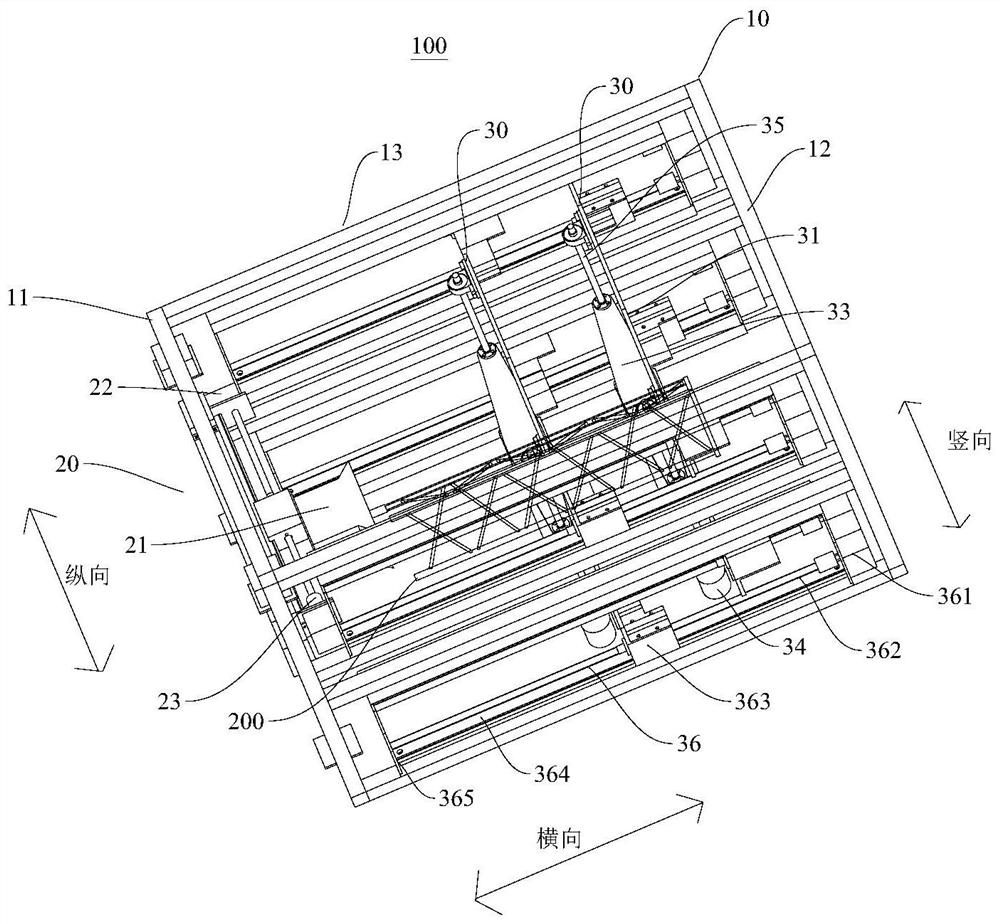

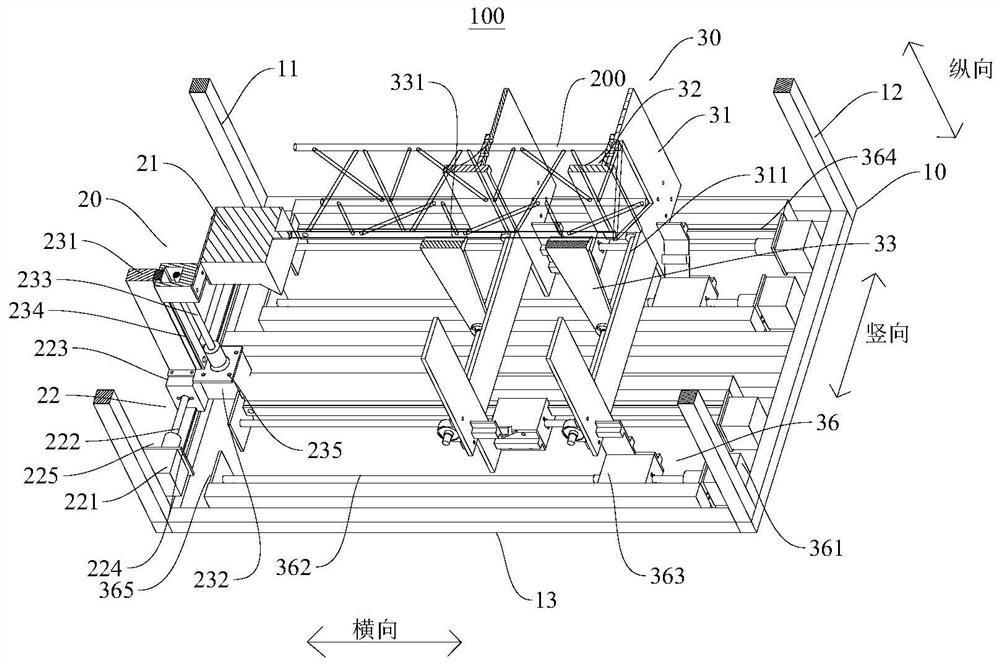

[0046] Refer below Figure 1-Figure 5 An on-orbit 3D printer 100 according to an embodiment of the present invention is described. The on-orbit 3D printer 100 can realize on-orbit printing of a truss structure, wherein the on-orbit refers to the space environment, which is different from the ground.

[0047] Such as Figure 1 ~ Figure 3 As shown, the on-rail 3D printer 100 according to the embodiment of the present invention includes: a frame 10, a spraying device 20 and two clamping devices 30, the spraying device 20 and the two clamping devices 30 are all arranged on the frame 10, and the frame 10 can Play the role of installation and protection. The two clamping devices 30 can cooperate with each other, so as to ensure the stability of their clamping of the printed part 200 .

[0048] Such as figure 1 and figure 2 As shown, the frame 10 is composed of a plurality of rod connections, wherein the frame 10 has a first bracket 11 and a second bracket 12 opposite in the lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com