Flexible material irregular shape cutting device

A flexible material and irregular technology, applied in the field of flexible material irregular shape cutting devices, can solve the problems of inconvenience, difficulty in meeting diversification, and inflexible cutting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

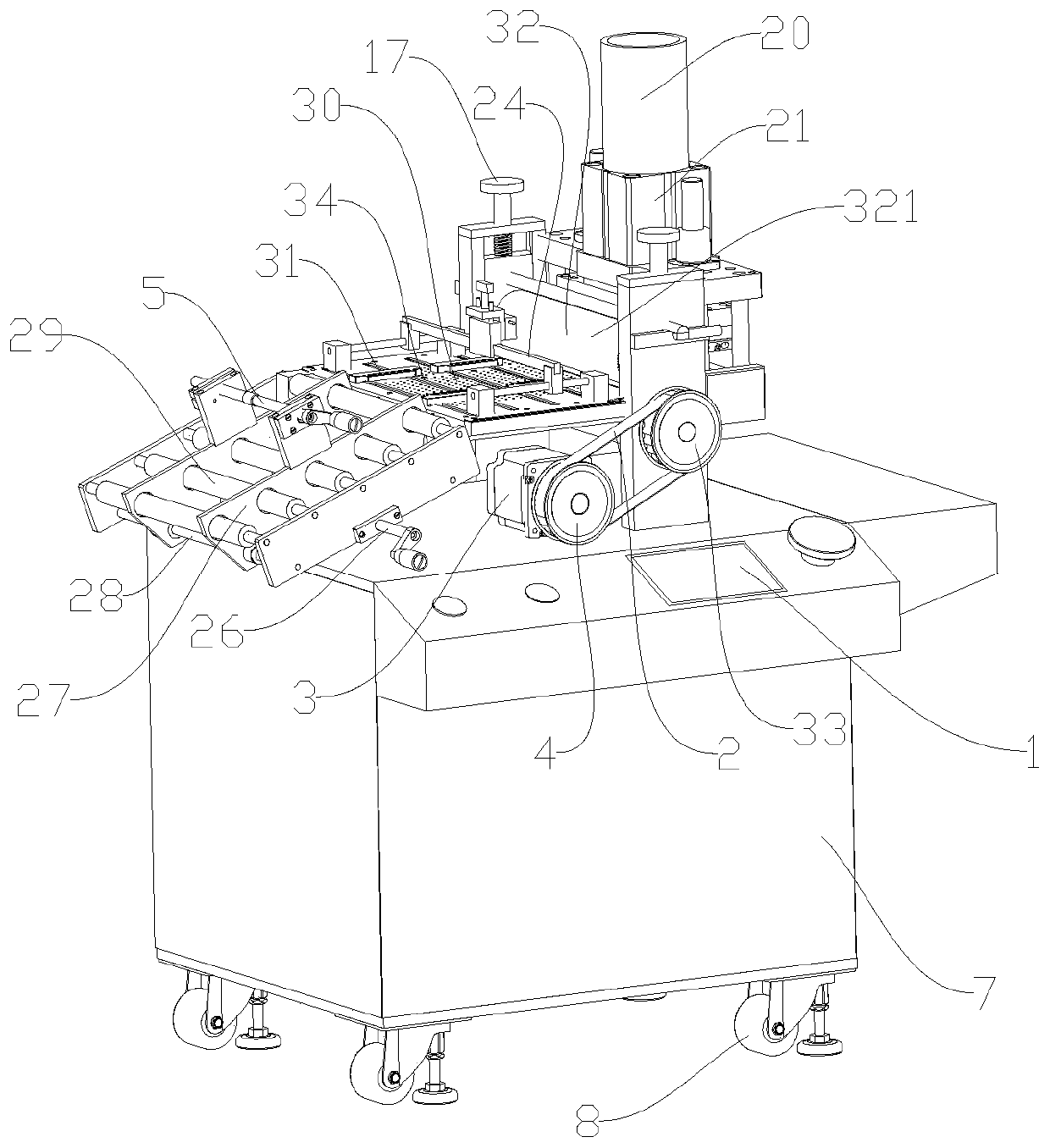

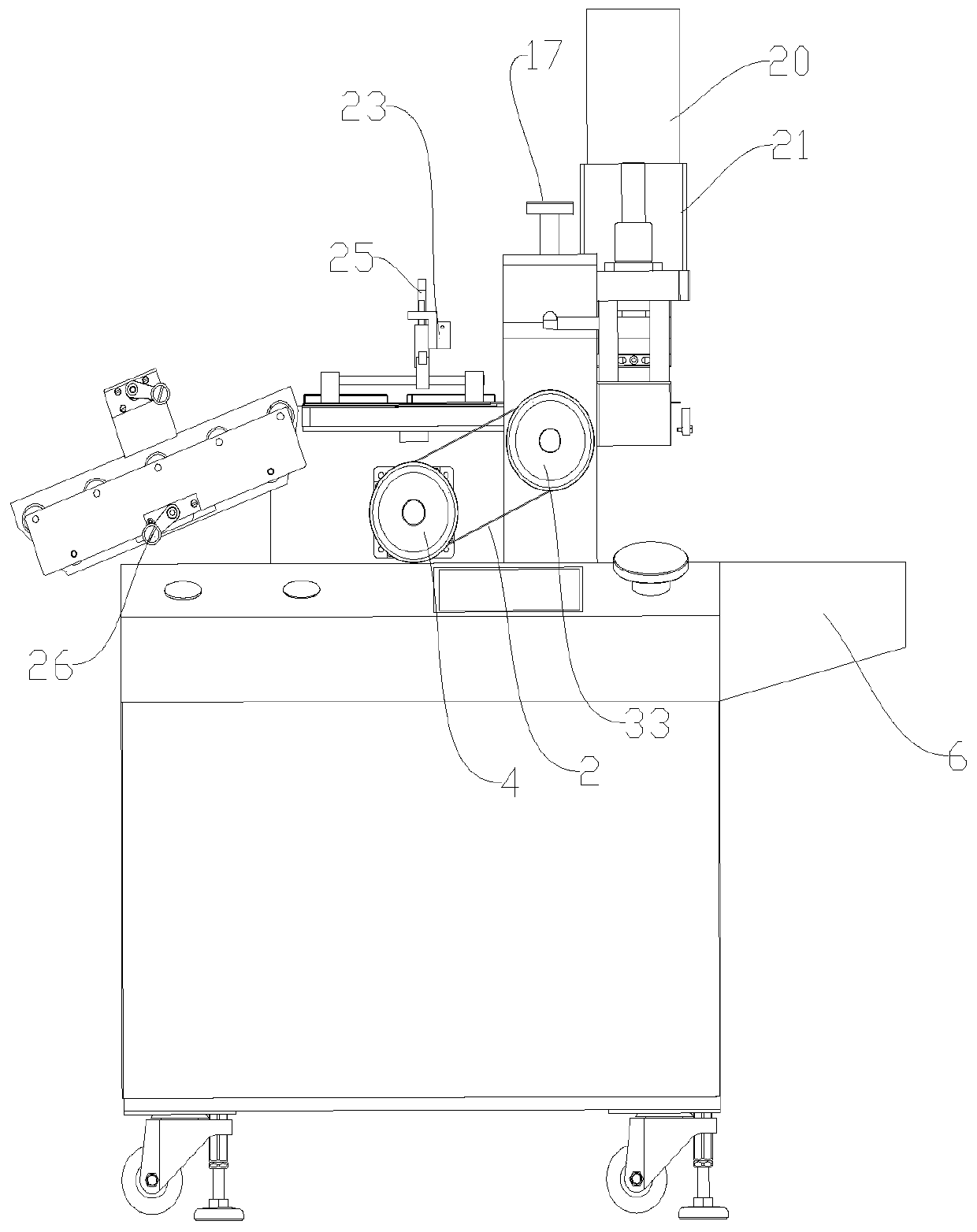

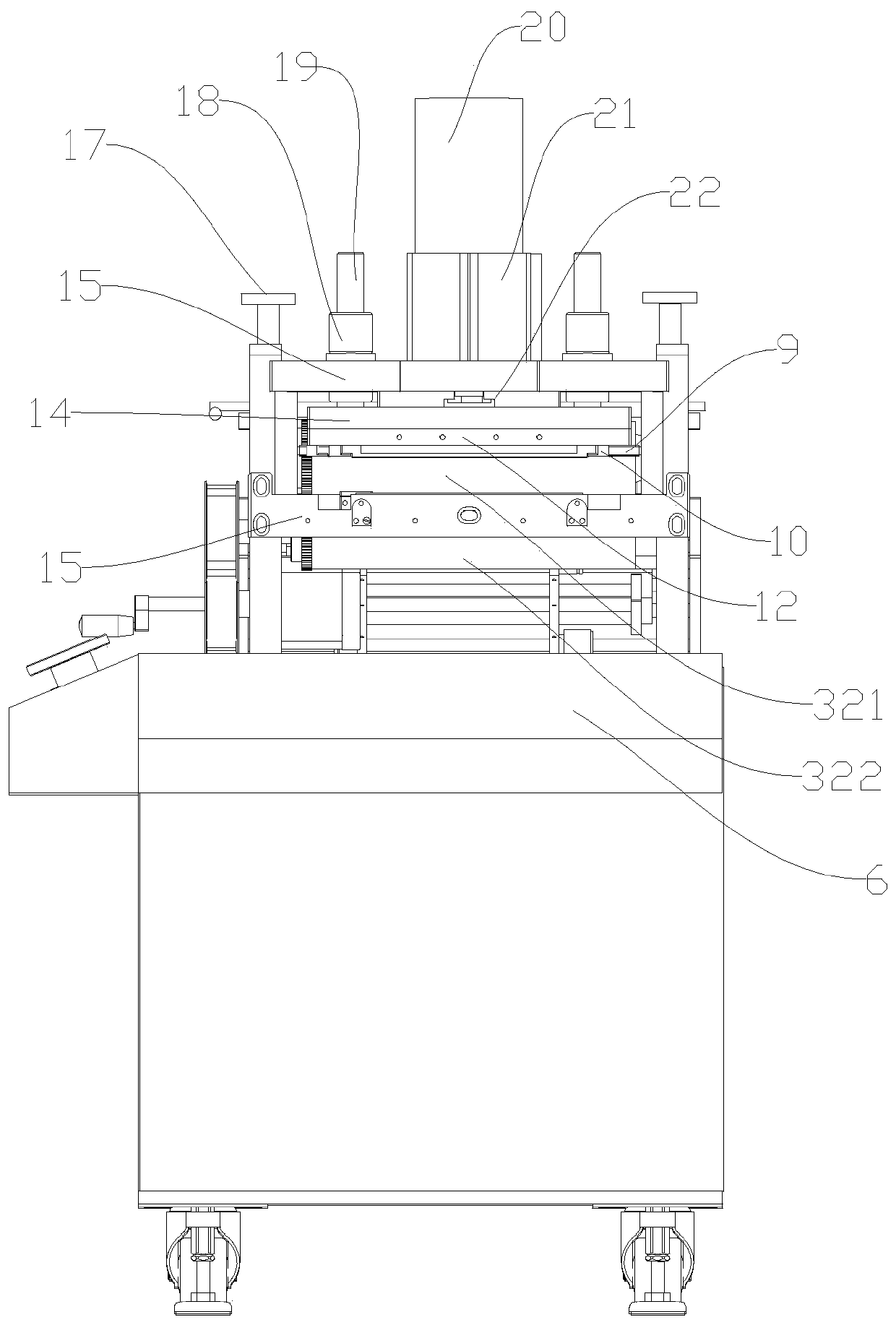

[0029] Figure 1 ~ Figure 4 A device for cutting irregular shapes of flexible materials according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a frame 7 on which a material conveying module, a material positioning and guiding module, a cutting module and a control system are arranged. The control system includes a man-machine interface touch screen 1. When cutting flexible materials, the required cutting requirements can be preset through the man-machine interface touch screen 1, and the control system gives instructions, and the flexible materials reach the cutting module for cutting under the pulling action of the material conveying module. Before the material reaches the cutting module, the position of the material can be adjusted and corrected through the material positioning and guiding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com