Vortex reactor and method of using same

A technology for reactors and reaction vessels, applied in chemical/physical/physicochemical stationary reactors, etc., can solve the problems of small effective reaction space, single flow form and fluid shear characteristics, and achieve extended residence time and structure Simple, easy to make and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

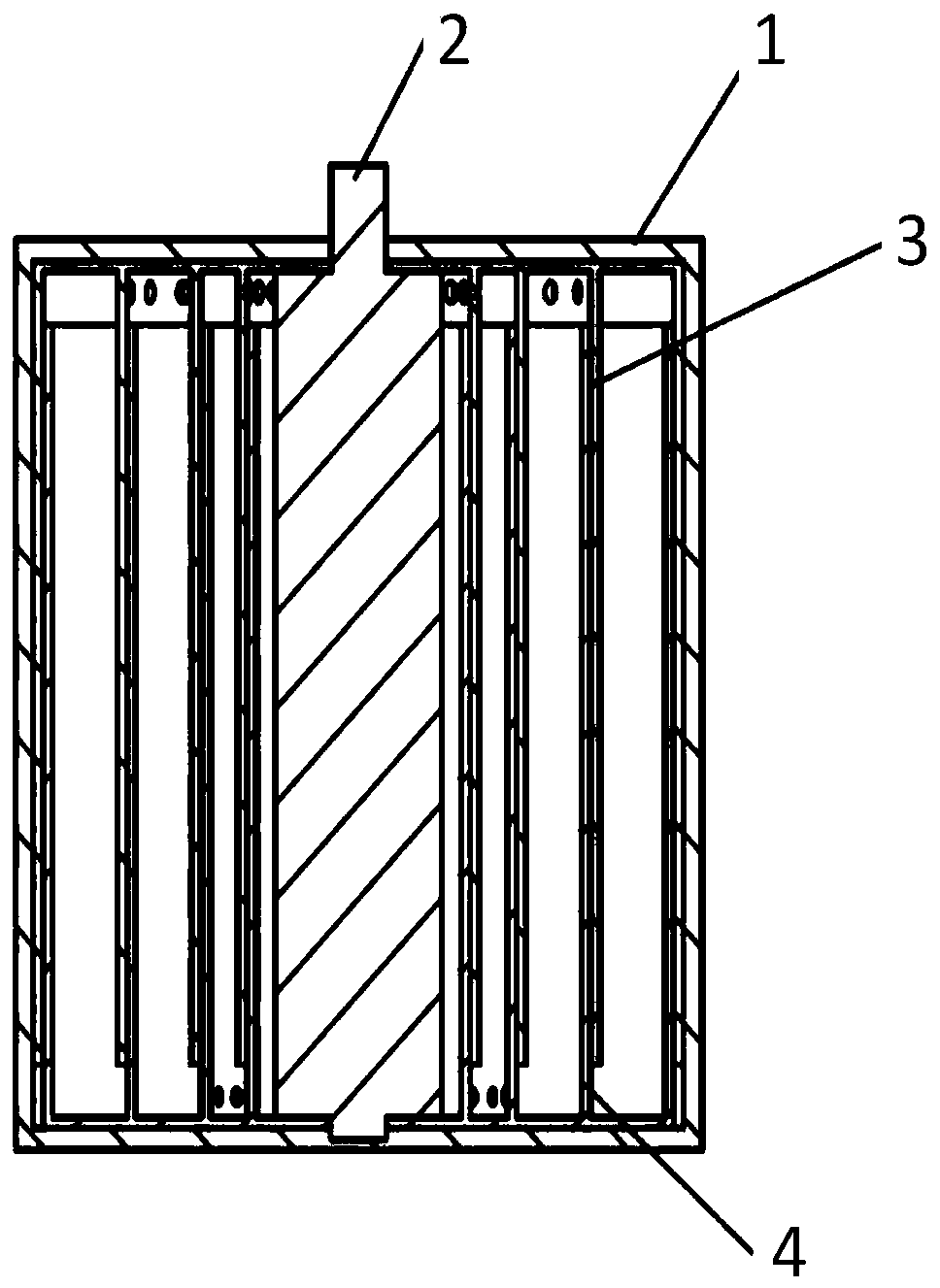

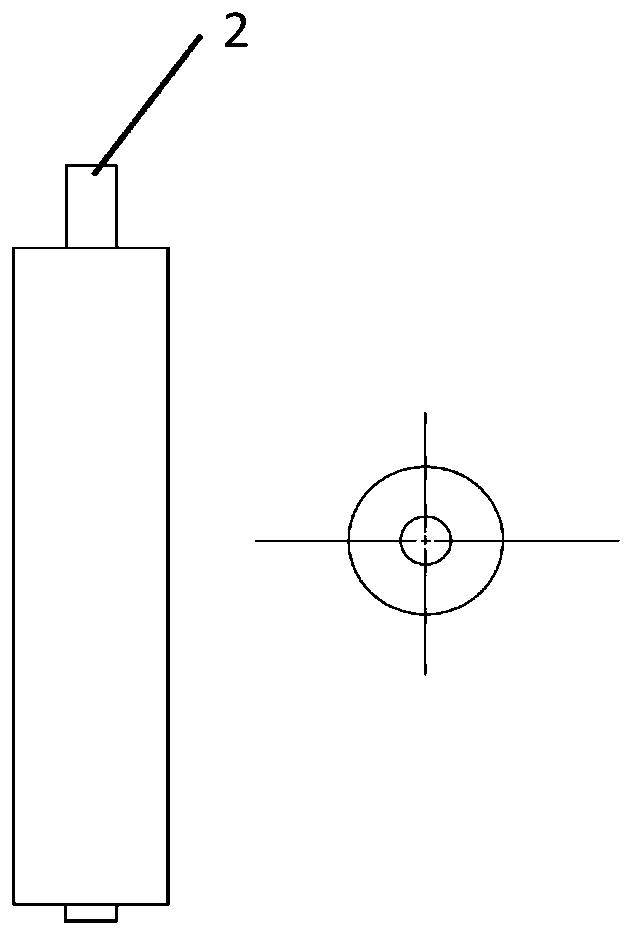

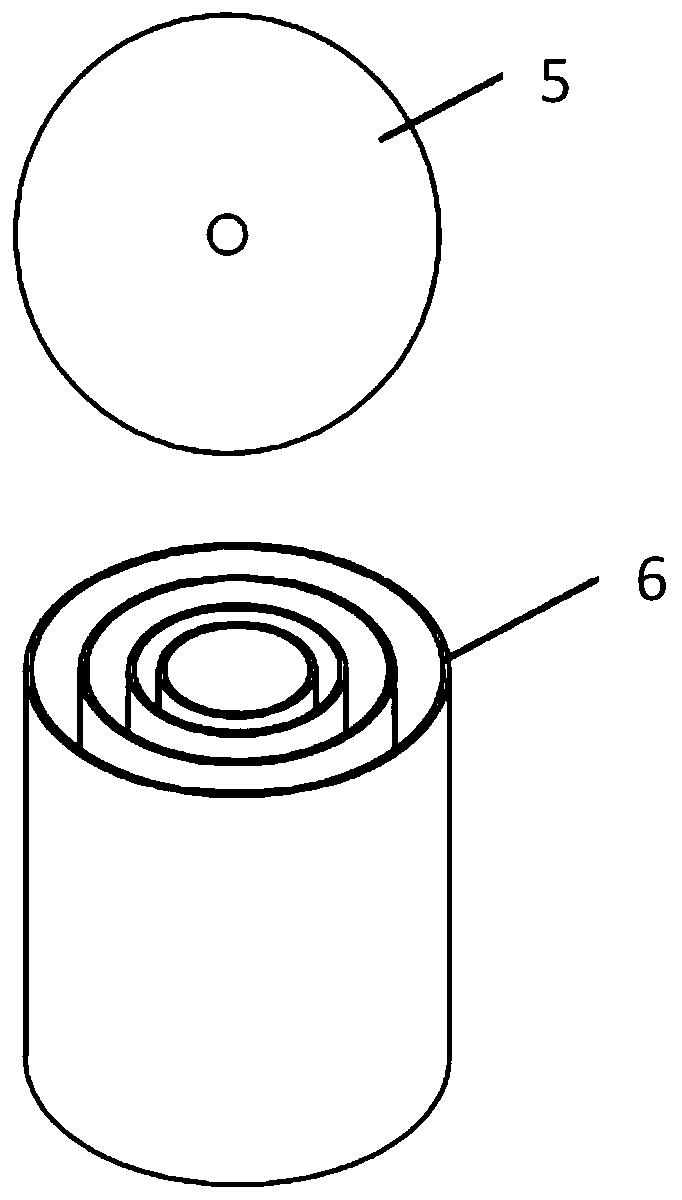

[0029] see figure 1 , a vortex reactor provided by an embodiment of the present invention, the reactor includes a reaction vessel 1, a rotating shaft 2, a rotor 3 and a stator 4, the reaction vessel 1 is a cylindrical structure, and the bottom is provided with a plurality of communicating external pipes inlet and outlet. A rotating shaft 2 is arranged at the center of the reaction vessel 1, such as figure 2 Shown is a schematic diagram of the connection relationship between the rotating shaft and the rotor according to an embodiment of the present invention. The rotor 3 is coaxially installed and fixedly connected to the rotating shaft 2. The rotating shaft 2 is driven to rotate by the motor. It is fixed on the bottom of the reaction vessel 1 and installed coaxially with the rotating shaft 2. The stator 4 and the rotor 3 are multi-layer nested cylindrical structures arranged coaxially at a certain radial distance, and the cylinders of each layer of the stator 4 are sleeved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com