Urban raised dust spraying apparatus and method thereof

A dust spraying and spraying device technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as inability to spray in time, waste of manpower and material resources, waste of resources, etc., to achieve good practical value and save space , prevent the effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

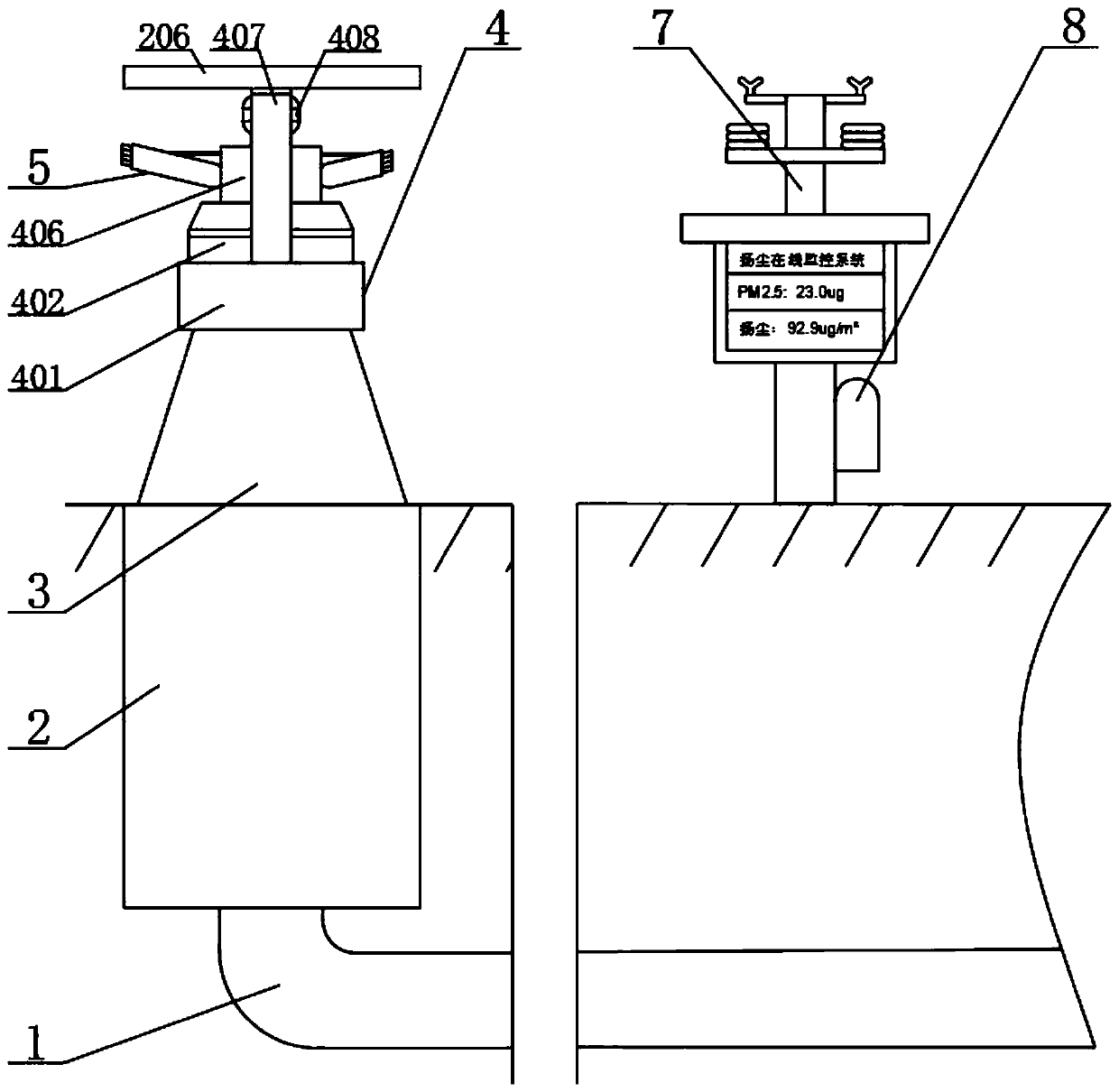

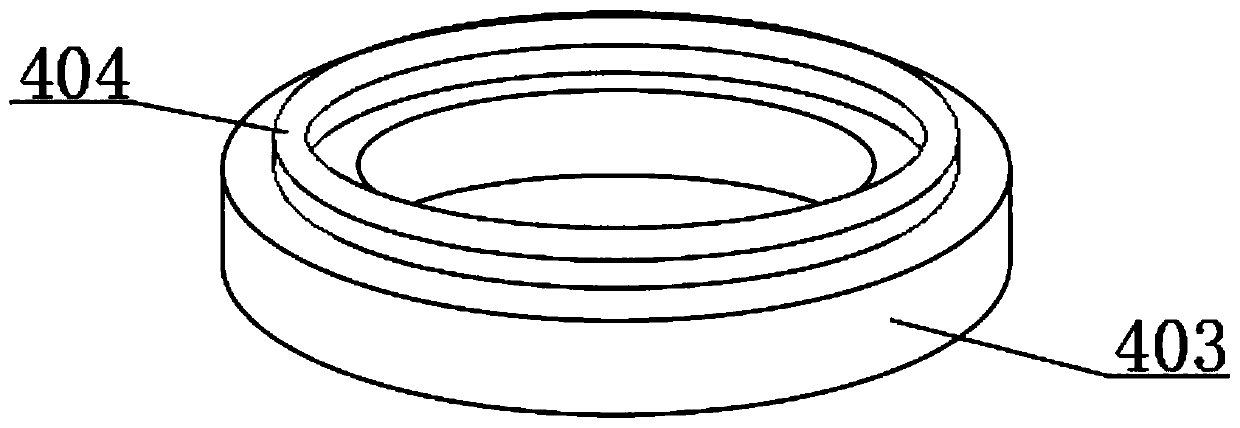

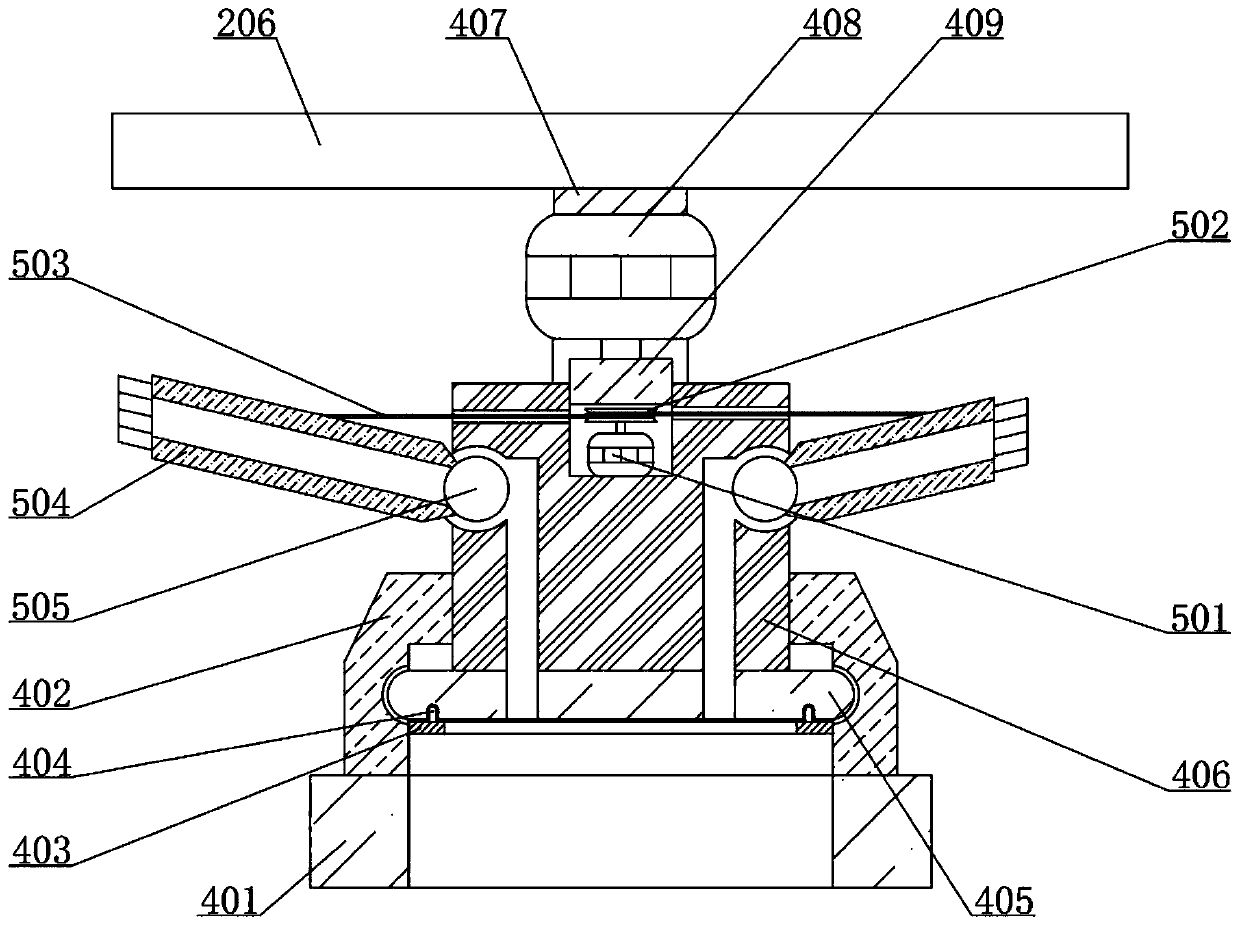

[0028] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present invention provides a technical solution:

[0029] An urban dust spraying device, comprising a water pipe 1, a lifting device 2, a lifting column 3 and a spraying device 4, the upper end of the water pipe 1 is connected with a lifting device 2, and the lifting device 2 includes a solenoid valve 201, a protective cylinder 202, a connecting pipe 203 and Cover plate 206, connecting pipe 203 is fixedly connected to the upper left side of water pipe 1, solenoid valve 201 is fixedly connected to the outer side of water pipe 1, and the outer side of water pipe 1 is fixedly connected to protective tube 202, and electric telescopic rods 204 are arranged on the left and right sides of solenoid valve 201, The lower end surface of the electric telescopic rod 204 is fixedly connected with the protective tube 202, the outer side of the sealing plate 205 is slidably connected with the protective tube 202, ...

Embodiment 2

[0037] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present invention provides a technical solution:

[0038] An urban dust spraying device, comprising a water pipe 1, a lifting device 2, a lifting column 3 and a spraying device 4, the upper end of the water pipe 1 is connected with a lifting device 2, and the lifting device 2 includes a solenoid valve 201, a protective cylinder 202, a connecting pipe 203 and Cover plate 206, connecting pipe 203 is fixedly connected to the upper left side of water pipe 1, solenoid valve 201 is fixedly connected to the outer side of water pipe 1, and the outer side of water pipe 1 is fixedly connected to protective tube 202, and electric telescopic rods 204 are arranged on the left and right sides of solenoid valve 201, The lower end surface of the electric telescopic rod 204 is fixedly connected with the protective tube 202, the outer side of the sealing plate 205 is slidably connected with the protective tube 202, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com