Fault analysis method and related equipment

A fault analysis method and faulty equipment technology, applied in the direction of instrumentation, error detection/correction, calculation, etc., can solve the problems of low network fault analysis efficiency, low resolution efficiency, complex log content structure, etc., to reduce fault maintenance costs and improve User experience, the effect of improving the efficiency of fault detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

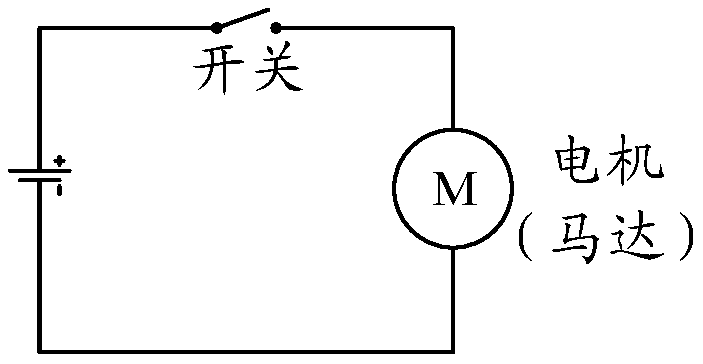

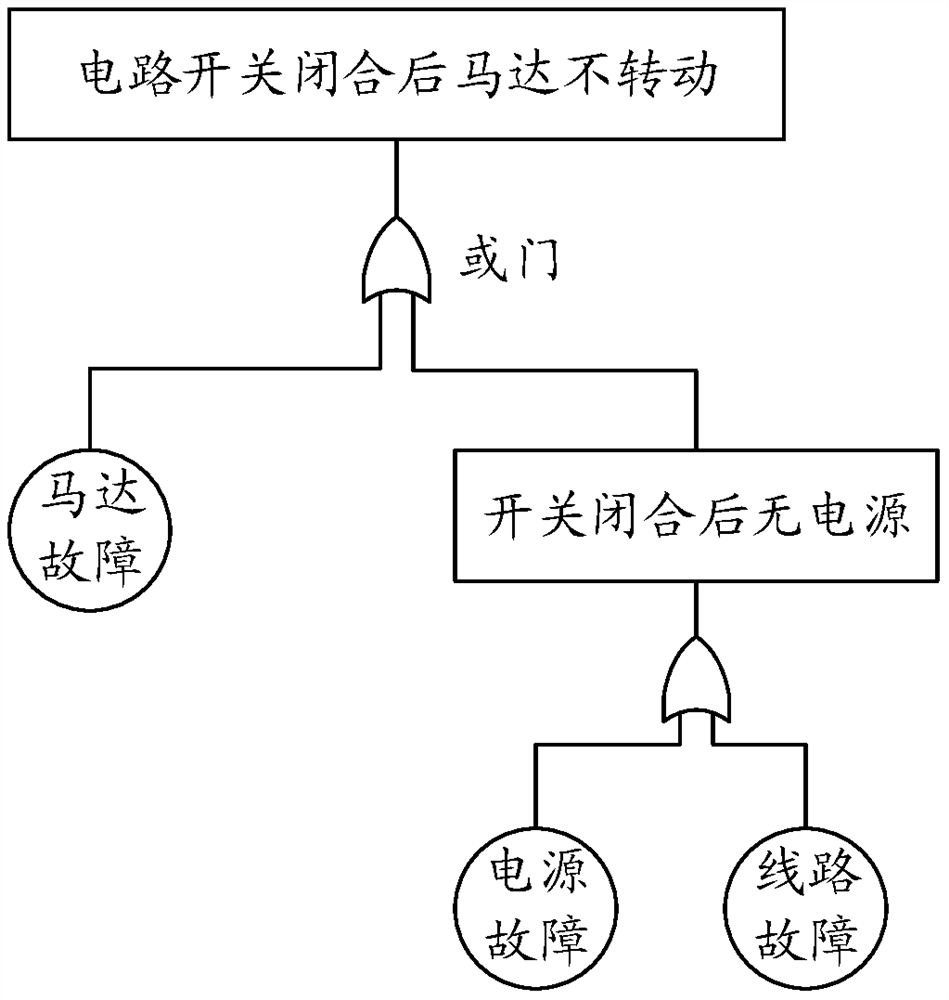

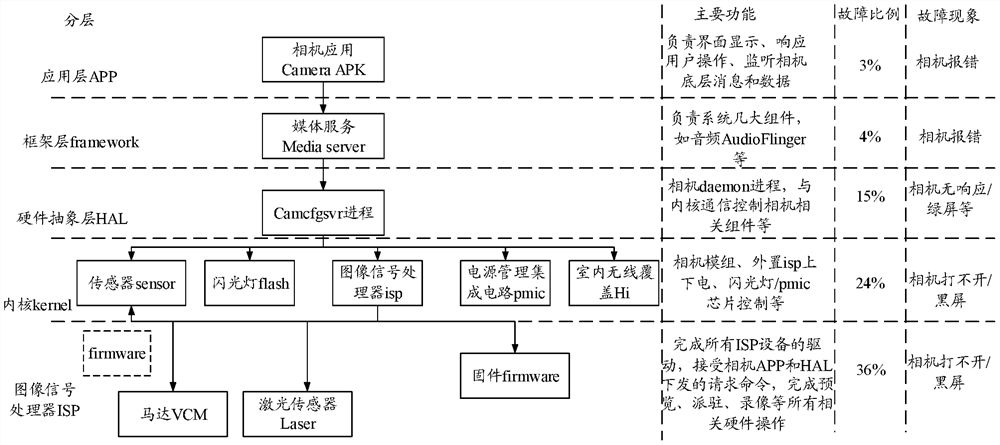

[0037] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings of the present invention.

[0038] The inventor of the present application discovered during the process of filing the present application that in the prior art, the following two solutions are adopted in order to determine and obtain the cause of the equipment failure.

[0039] In the first solution, relying on the experience of the maintenance engineer will increase the labor cost and the maintenance time will be too long. Especially for some complex faults, the maintenance engineer cannot rely on the experience to know the cause of the fault, and the fault detection rate is low. Equipment maintenance time.

[0040] In the second solution, by analyzing the log records of the equipment, combined with the diagnosis and analysis of the maintenance engineer, the cause of the equipment failure is located and the corresponding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com