Sealing joint for gas insulation switch cabinet

A technology for gas-insulated switches and sealed joints, applied in switchgear, switchgear settings, electrical components, etc., can solve the problems of long delivery time, high price, inability to meet sealing reliability, etc., to avoid sealing damage, Improve sealing reliability and avoid sealing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

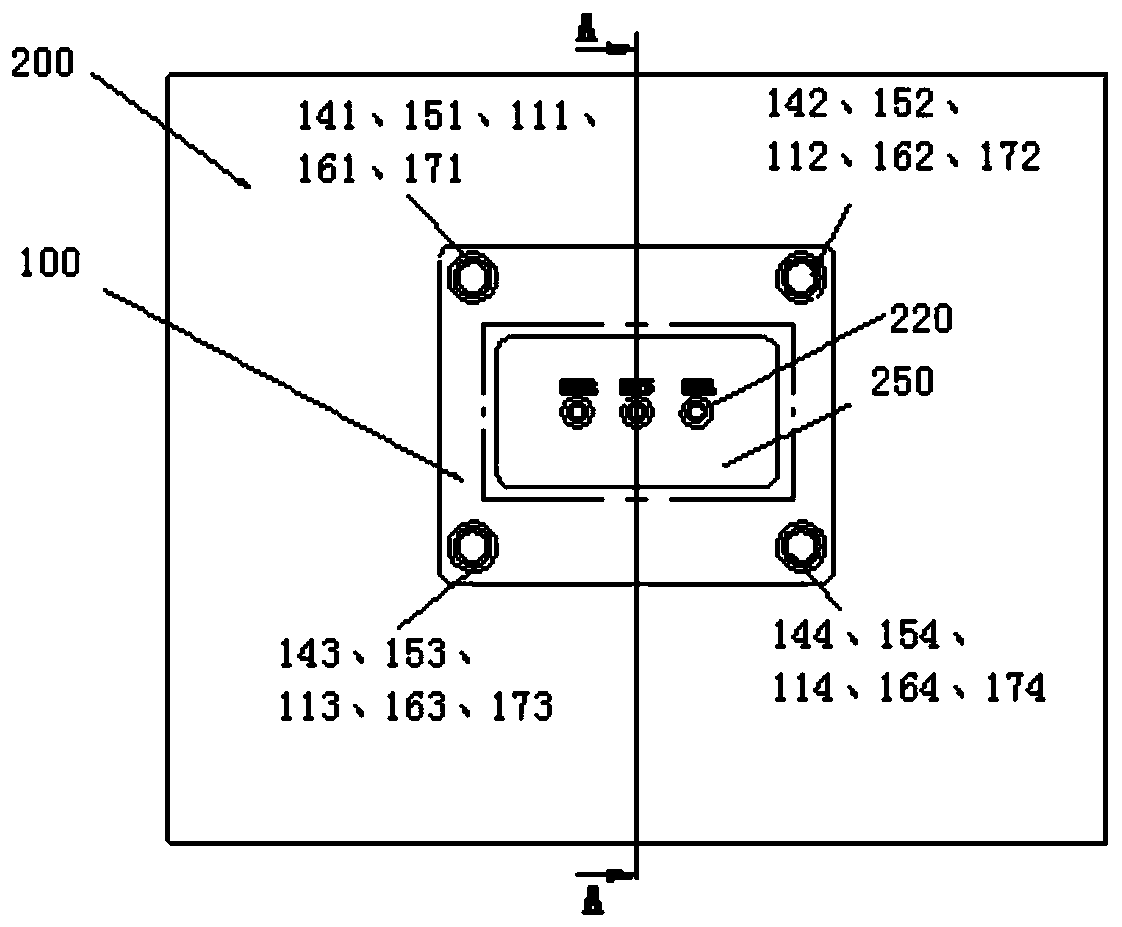

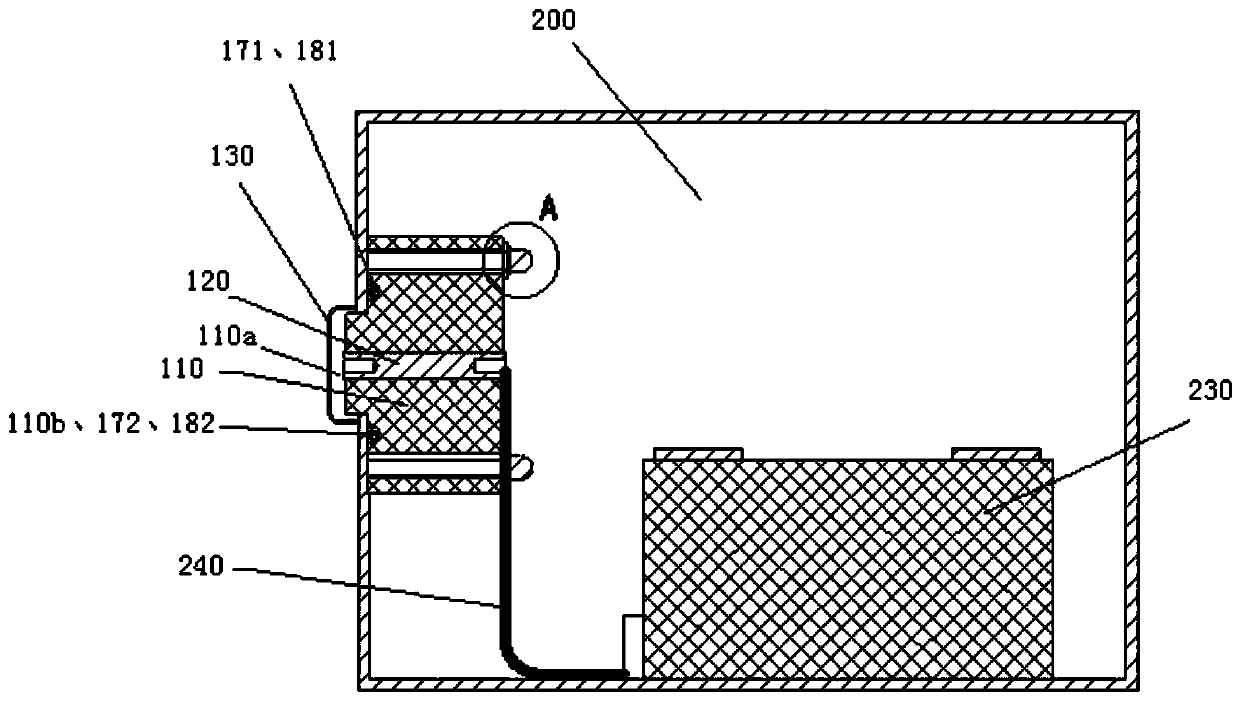

[0031] like Figure 1-4 The shown sealing joint 100 for gas-insulated switchgear includes an epoxy resin sealing body 110 , and the epoxy resin sealing body 110 is integrally fixed at the opening 210 of the gas-insulated switchgear 200 .

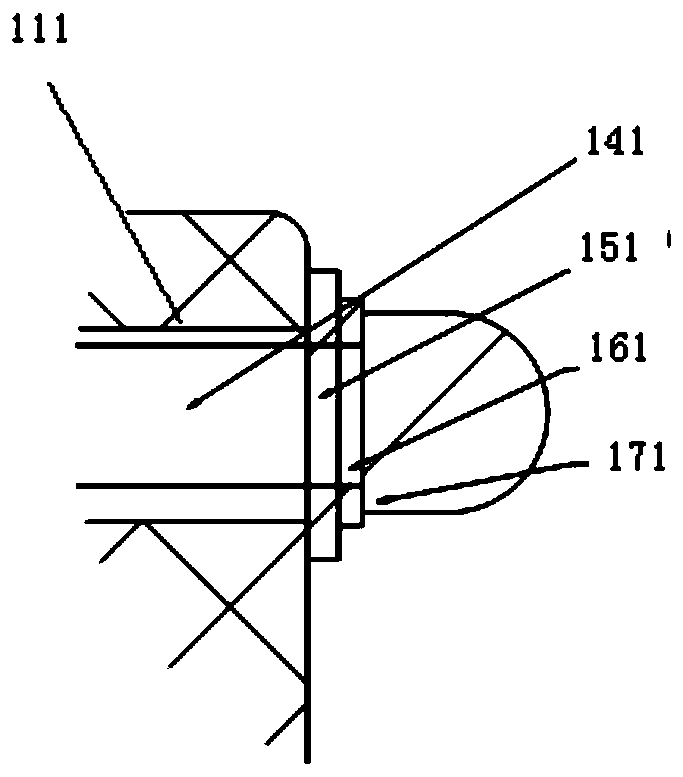

[0032] key combination figure 2 , a metal insert 120 runs through the epoxy resin sealing body 110, the epoxy resin sealing body 110 expands outward at one side 110a close to the opening 210 of the gas insulated switchgear 200, and the length of the metal insert 120 is not shorter than that of the epoxy resin sealing body 110. The longest part 110a after the expansion of the middle part of the resin sealing body 110.

[0033] And a protective cover 130 is opened outside the opening 210 of the gas insulated switchgear 200 .

[0034] key combination figure 2 and Figure 4 One end 121 of the metal insert 120 close to the opening 210 of the gas insulated switchgear 200 is provided with an internal thread groove 121a, and the other end 122 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com