Multi-stage internal circulation drying machine for biomass fuel preparation

A biomass fuel, internal circulation technology, applied in biomass drying, dryer, drying and other directions, can solve problems such as hidden safety hazards, material fire, easy to produce sparks, etc., to reduce dust, extend length, and prevent sparks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

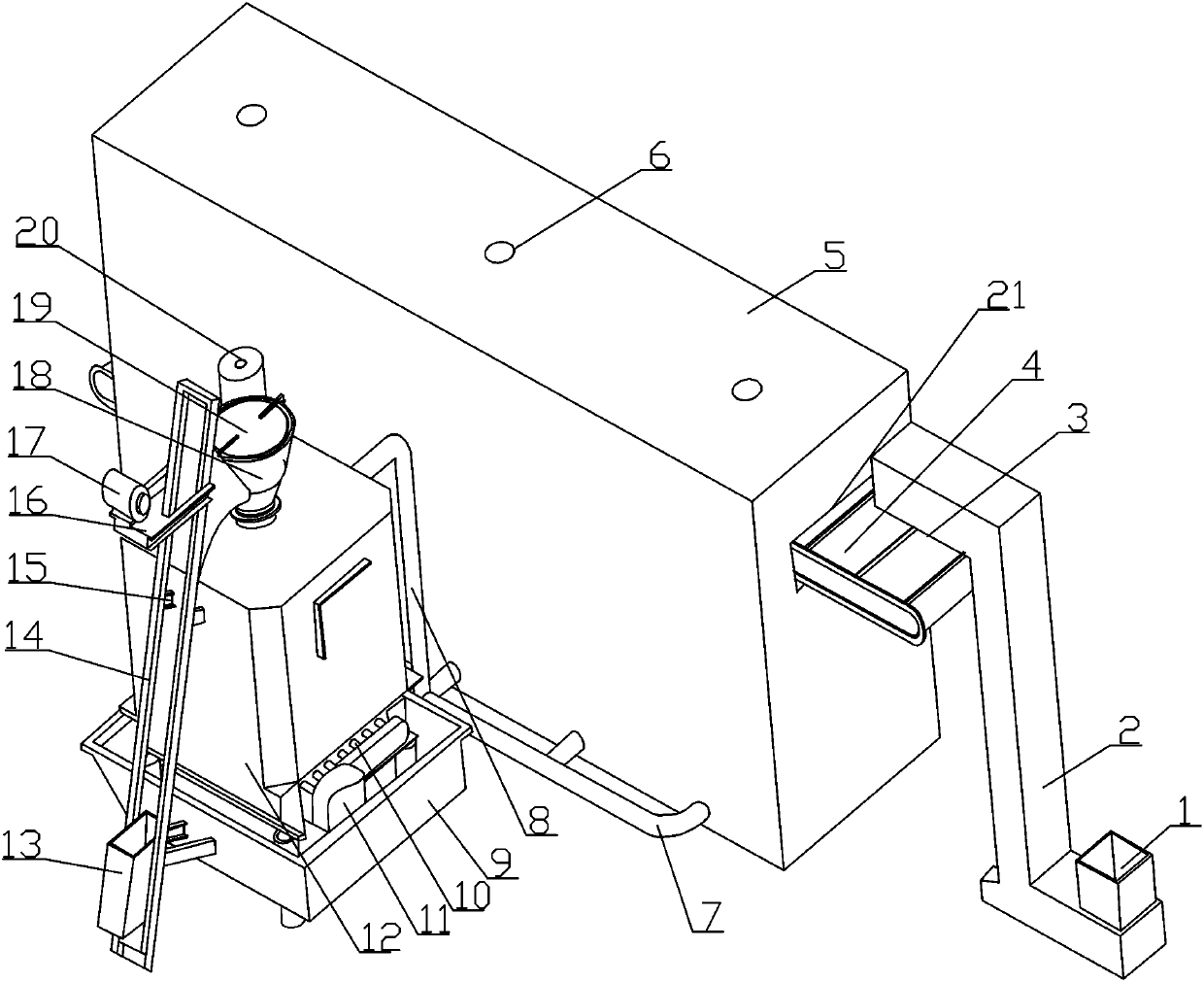

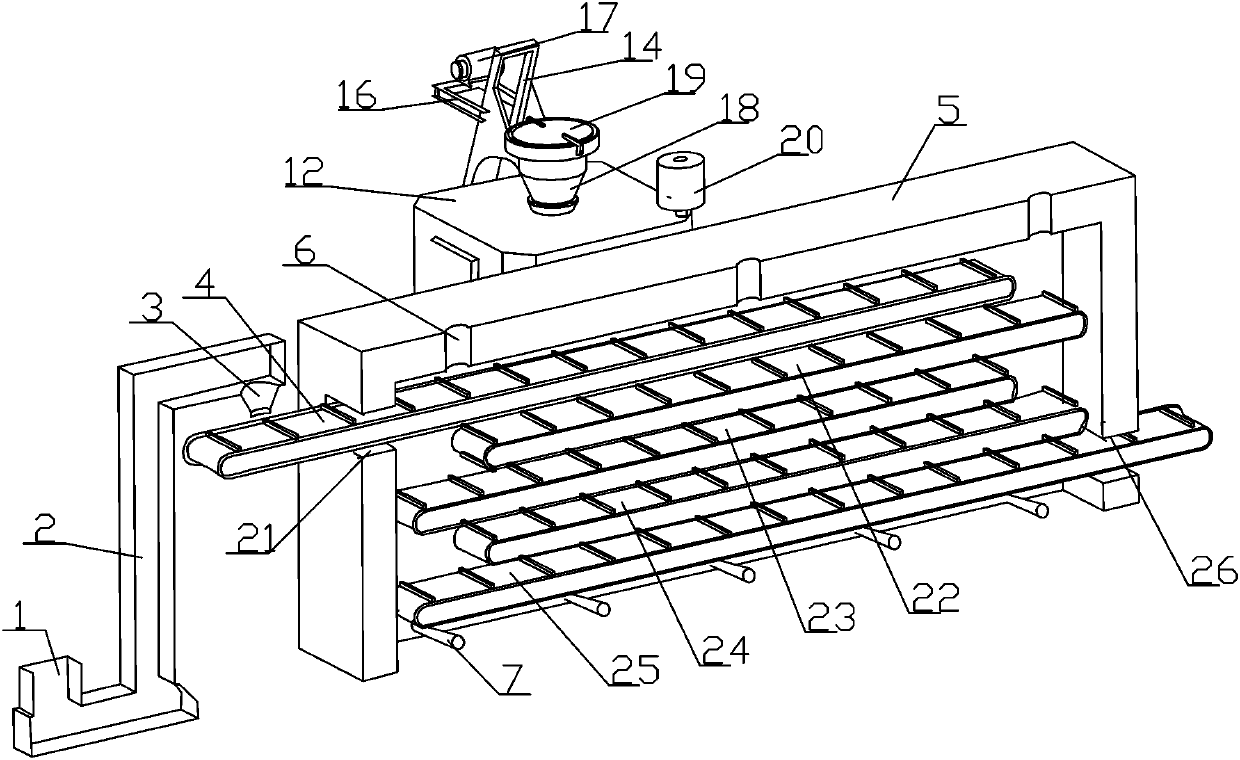

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] join Figure 1-2 , multi-stage internal circulation biomass fuel preparation dryer, which includes a drying box 5, the top of one side of the drying box 5 is provided with a feed port 21, the position of the feed port 21 protrudes a The primary material conveyor belt 4, the primary material conveyor belt 4 outside the drying box 5 is connected to the material lifting device for supplying the material to be dried; Below, from top to bottom, there are two-stage material conveyor belt 22, three-stage material conveyor belt 23, four-stage material conveyor belt 24 and five-stage material conveyor belt 25; The discharge port 26 on the drying box body 5; the bottom of the side of the drying box body 5 is provided with a plurality of hot air pipes 7 arranged side by side, and the hot air pipes 7 extend into the inside of the drying box body 5, and The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com