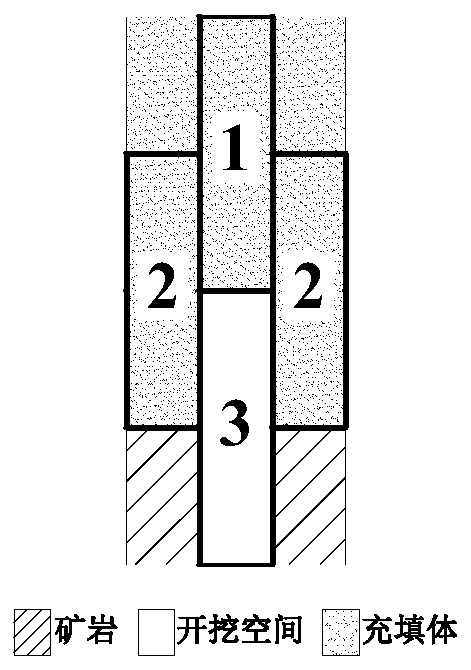

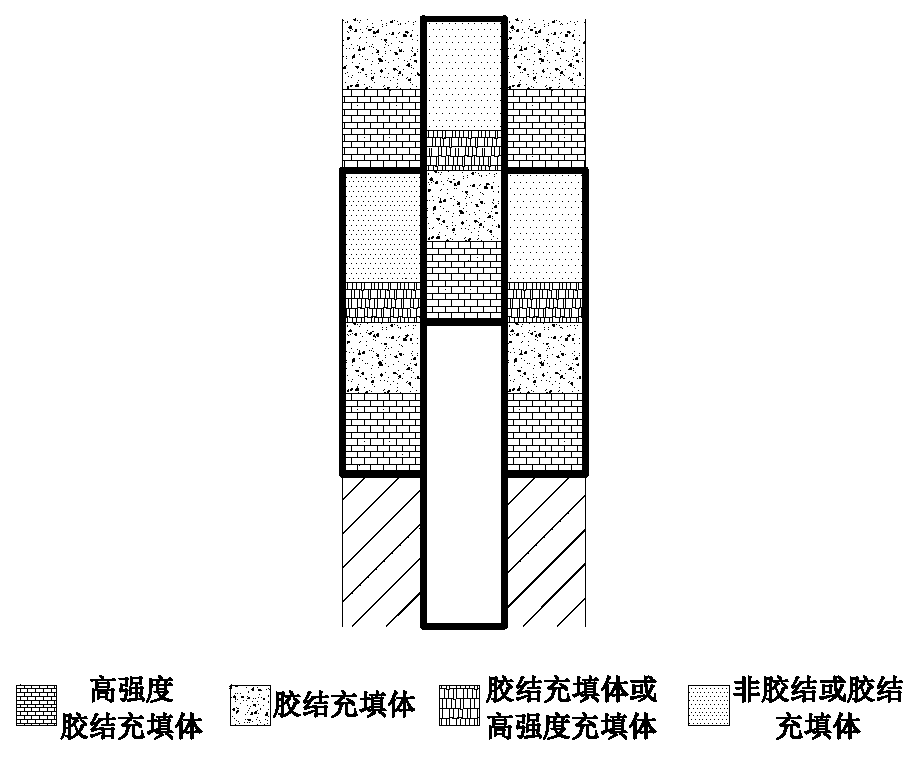

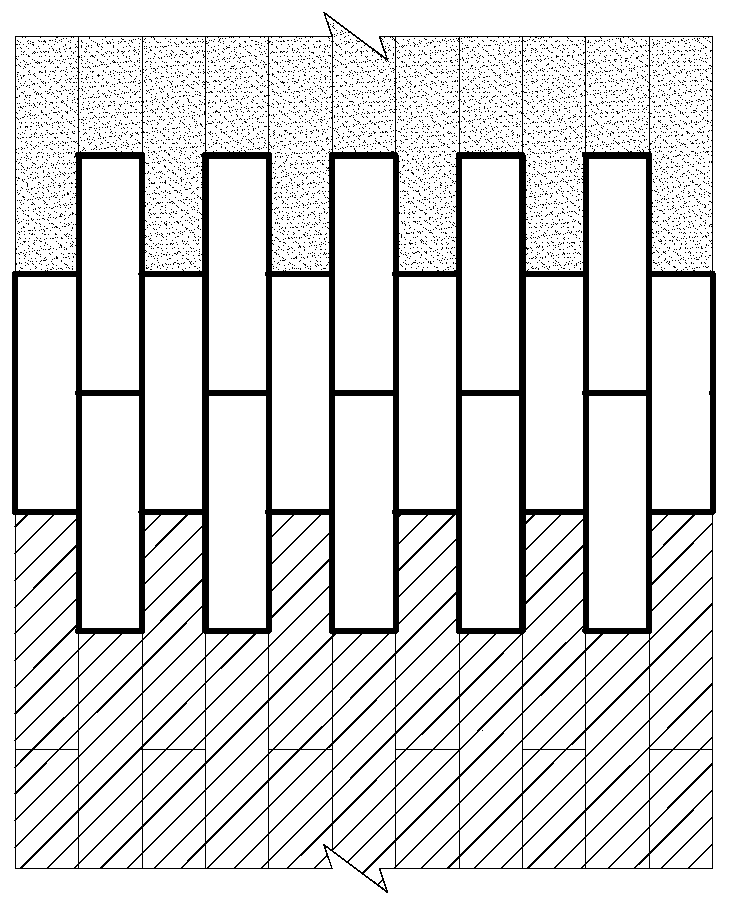

Descending open stope subsequent filling mining method

A filling mining method and open field technology, applied in underground mining, filling, surface mining, etc., can solve the problems of low mining efficiency, high labor cost, high material cost, etc., and achieve high mining efficiency, high degree of mechanized operation, and mining field production capacity large effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0094]As an example of using the present invention in the field, for example, a large-scale underground metal mine has an annual output of about 1.5 million tons of ore, and the ore grade and value are relatively high. The main ore body is about 1,500 meters long along the strike, and about 1,700 meters long in the direction. The distribution scale is large and the overall thickness is thick. The ore body is moderately inclined to inclined, with a dip angle of about 50-70°.

[0095] The fault structure is developed in the mining area, the ore-controlling structural alteration zone is relatively thick, and the engineering geological conditions are complex. Although the rock is relatively hard, the structural plane is well developed, which directly affects the quality of the rock mass. The orebodies mainly occur in granitic cataclysmic dikes, and the rock mass quality of the ore body is generally to extremely poor. The rock mass quality of the shallow ore body is better than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com