Physical simulation experiment oil sand processing device and processing method

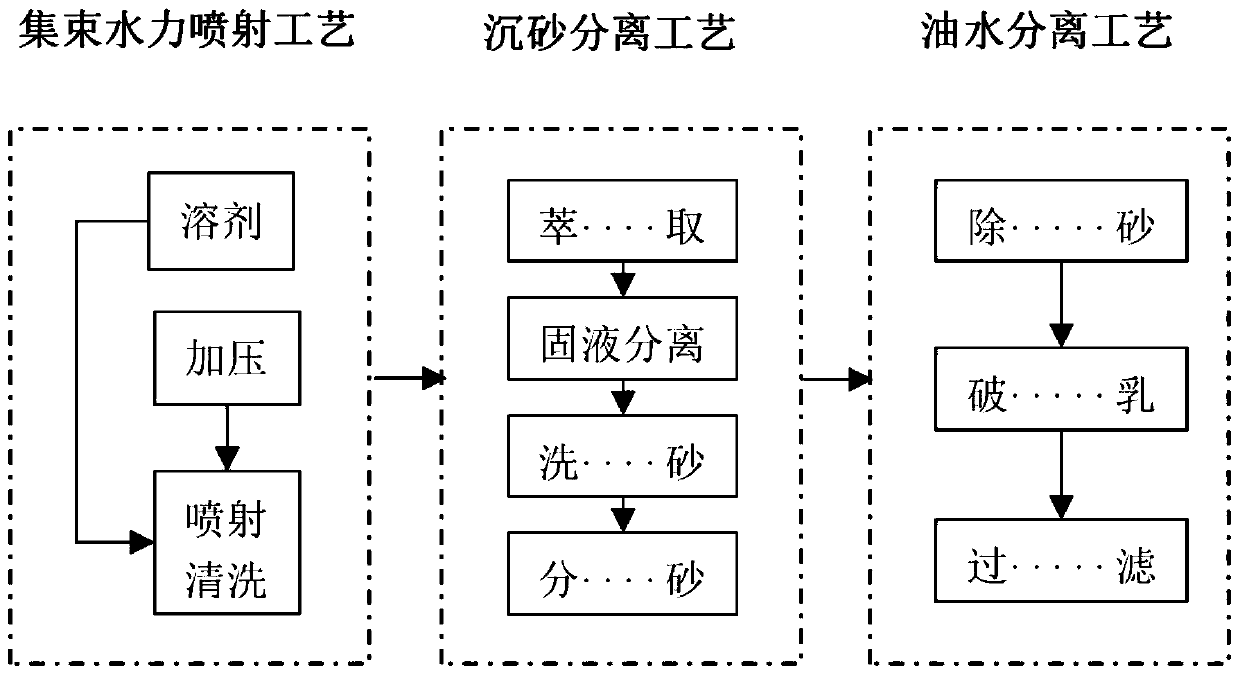

A technology of physical simulation and treatment method, applied in mechanical dehydration/demulsification, petroleum industry, teaching model, etc., can solve the problems of slow oil sand treatment efficiency, affecting large-scale physical simulation experiments, low efficiency, etc., and achieves short cycle time , Improve the effect of maximum utilization and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

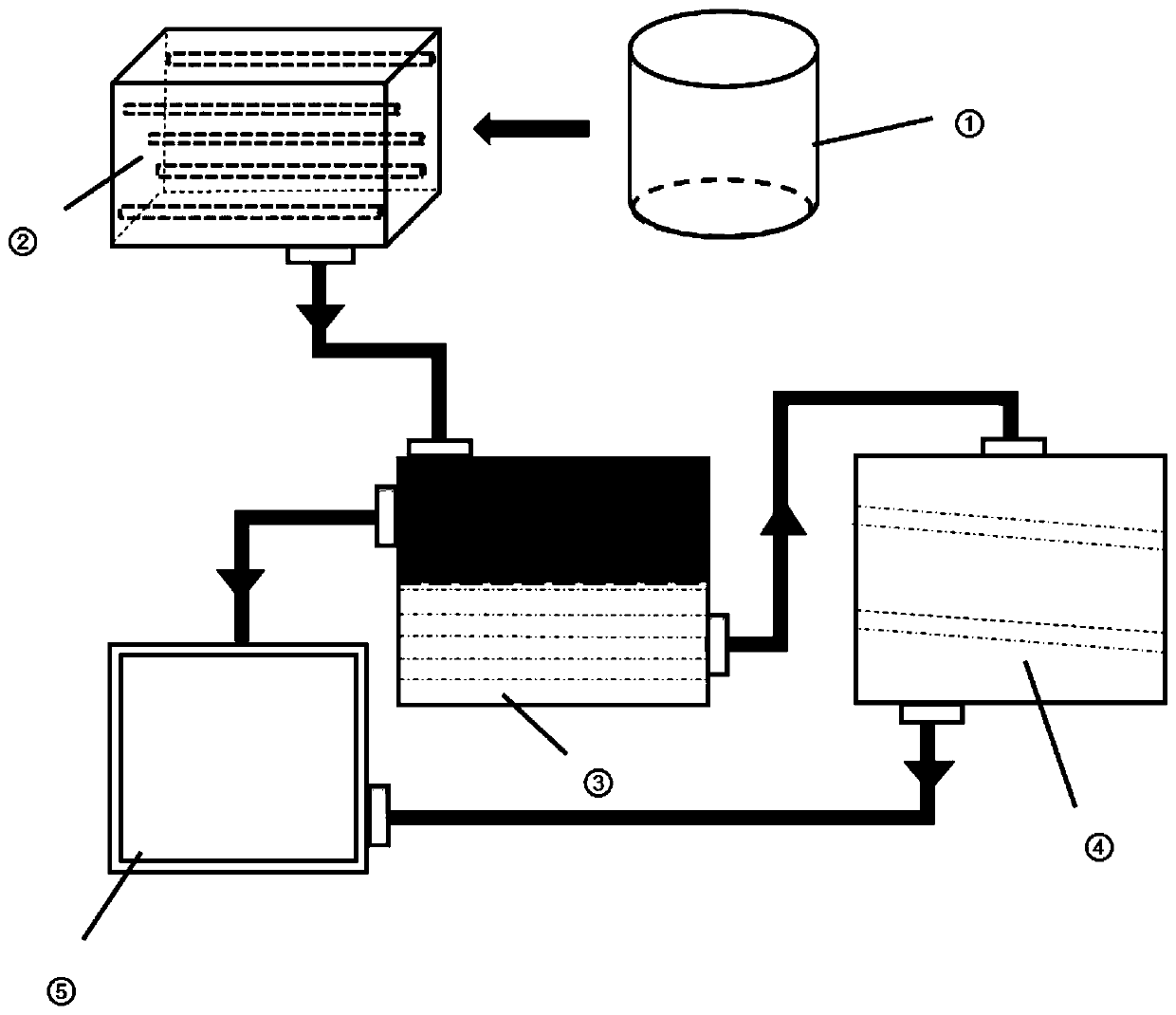

[0065] This embodiment 1 provides a physical simulation experiment oil sand treatment device, the outlet of the booster pump 1 is connected with the sand filling model 2 through a pipeline, the inlet of the booster pump 1 is connected with an extraction agent storage device, and the booster pump 1. The oil sand in the sand packing model is sprayed with extractant through the pipeline;

[0066] The sand filling model 2 is communicated with the settling container 3, and the mixture of sand particles and crude oil washed by the extractant in the sand filling model 2 enters the settling container 3, and the settling container 3 can mix solids such as sand particles and liquids such as crude oil and extractant separated;

[0067] The settling vessel 3 is communicated with the oil-water separator 4, and the liquid obtained by solid-liquid separation in the settling vessel 3 enters the oil-water separator 4, and the oil-water separator 4 is also provided with an opening for adding to...

Embodiment 2

[0070] The oil sand treatment device for the physical simulation experiment in Example 1 is used to process the oil sand in the physical simulation experiment, and recover the oil, sand and oil washing water used in the experiment.

[0071] The experimental sand treatment steps are as follows:

[0072] a. The extractant kerosene is introduced into the sand filling model 2 through the booster pump 1, and the oil sand is sprayed with cluster water. The mixture of washed down sand grains, extractant and crude oil in the sand filling model 2 is introduced into the settling container 3;

[0073] The content of sand filling model 2 is 100kg of oil sand, containing 10% oil, and 125L of extractant is used in step 1.

[0074] b. After the mixture completely enters the settling vessel 3, it passes through the gravity settling method in the settling vessel 3 to complete the solid-liquid separation. Get the sand for the experiment.

[0075] c, the liquid obtained by filtering in the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com