Direct-current relay capable of resisting short circuit current and extinguishing arc

A DC relay, anti-short-circuit technology, applied in circuits, electrical switches, electrical components, etc., can solve problems such as the failure of bounce and arcing, the inability of dynamic and static contacts to contact and close reliably, and achieve strong short-circuit resistance and improve short-circuit resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

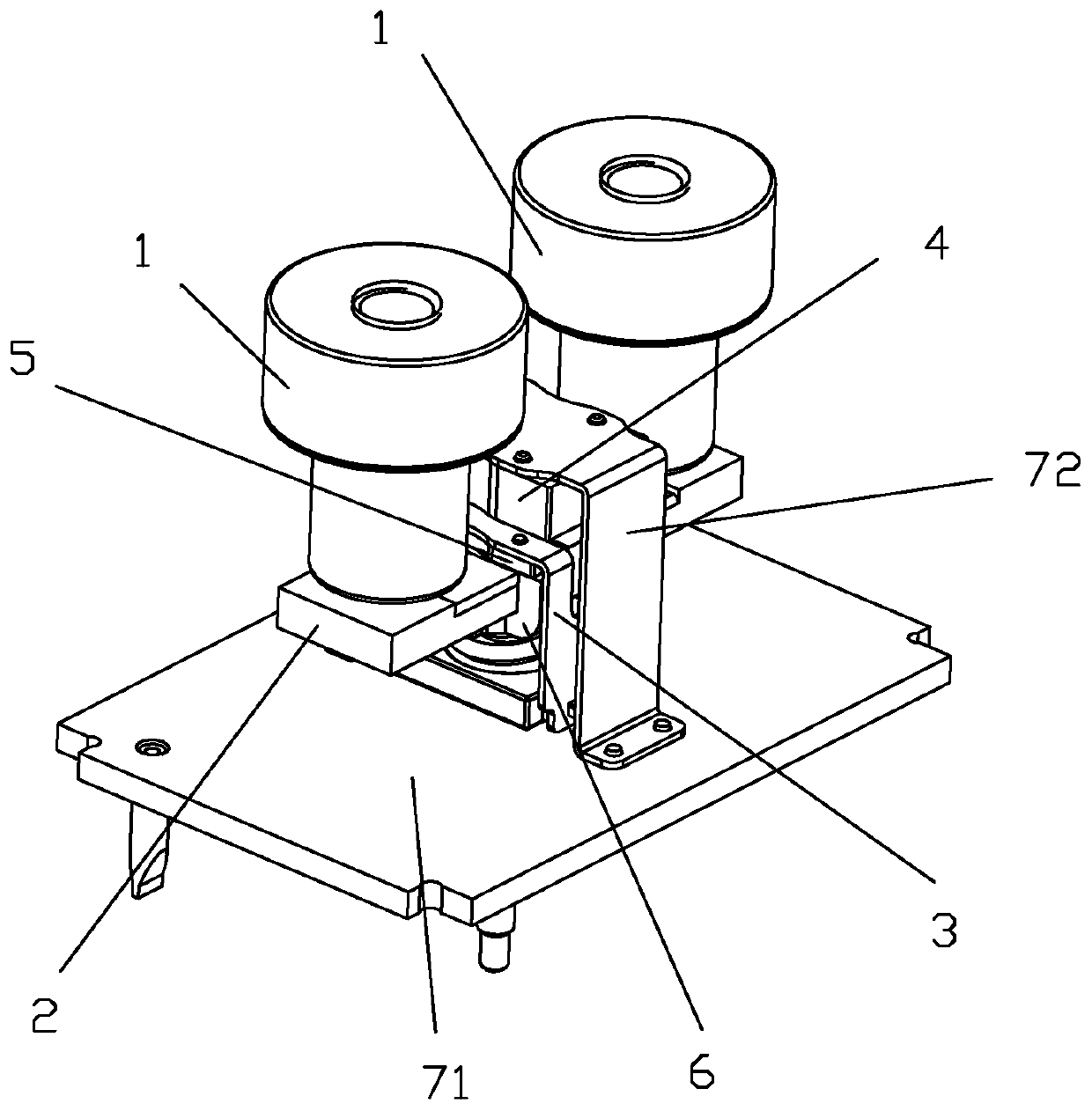

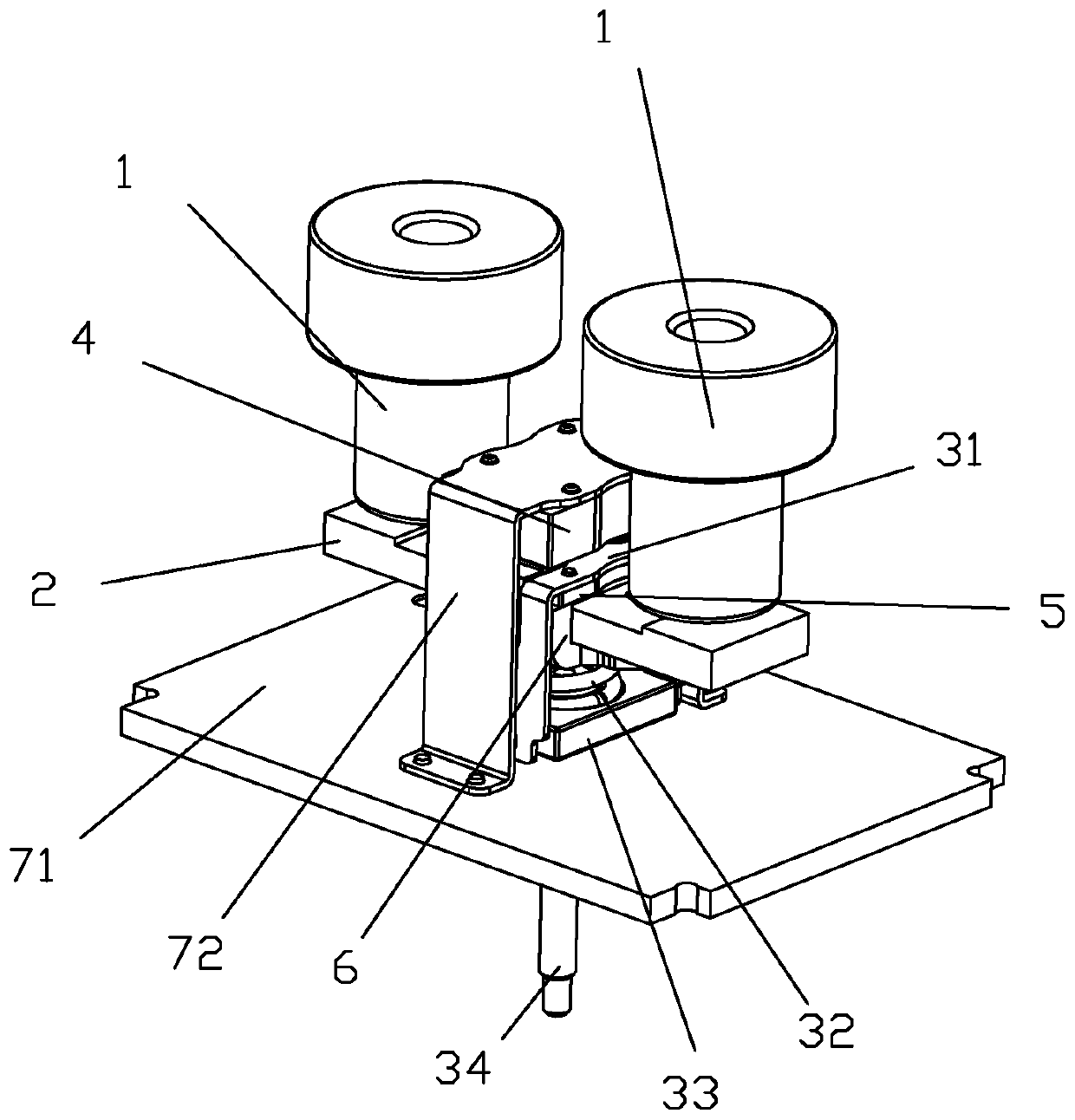

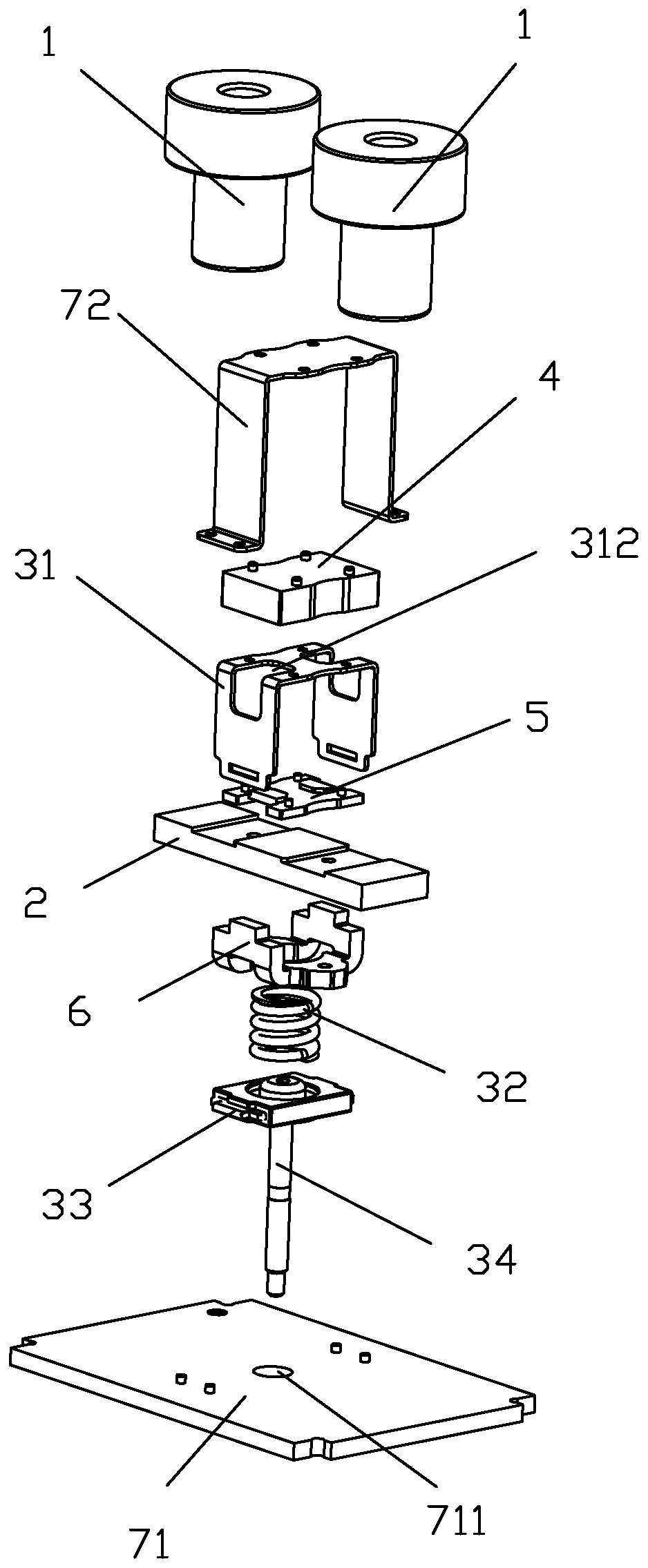

[0050] see Figure 1 to Figure 11 As shown, a DC relay capable of resisting short-circuit current and arc extinguishing of the present invention includes two static contact terminals 1, a straight-type moving reed 2 and a push rod part 3; the moving reed 2 is installed in the push rod part 3, so that under the action of the push rod part 3, the moving contacts at the two ends of the moving reed 2 are matched with the static contacts at the bottom of the two static contact lead-out ends 1; in this embodiment, the moving The two ends of the reed 2 constitute the moving contact of the moving reed 2, and the bottom end of the static contact lead-out 1 constitutes the static contact of the static contact lead-out 1; the DC relay also includes a fixed upper Yoke 4, a follow-up upper yoke 5 and a lower armature 6; the fixed upper yoke 4 is fixed above the push rod part 3 corresponding to the position between the two moving contacts of the moving reed 2 , the follow-up upper yoke 5 i...

Embodiment 2

[0062] see Figure 11 to Figure 16 As shown, a kind of arc extinguishing and anti-short circuit current DC relay of the present invention is different from Embodiment 1 in that a magnetic steel 81 for arc extinguishing is also arranged beside the contacts; The magnetic steel 81 is two pieces, and the two magnetic steels 81 are respectively configured at the positions corresponding to the dynamic and static contacts outside the two ends of the length of the moving reed 2, and the magnetic poles on the opposite sides of the two magnetic steels 81 are set for the opposite.

[0063] In this embodiment, the DC relay also includes two U-shaped yoke clips 82, the U-shaped bottom walls of the two yoke clips 82 are respectively connected to the opposite sides of the two magnets 81, and the two yoke clips 82 The ends of the two side walls of the U-shape respectively exceed the relative positions of the corresponding movable and static contacts and are close to each other at the middle po...

Embodiment 3

[0066] see Figure 17 to Figure 21 As shown, a kind of arc extinguishing and anti-short-circuit current DC relay of the present invention is different from Embodiment 1 in that a magnetic steel 91 for arc extinguishing is also arranged beside the contacts; There are three magnetic steels 91, two of which are respectively arranged on the outer sides of the width of the movable reed 2, and are in a position corresponding to one of the dynamic and static contacts (right side) in the three magnetic steels 91. , and the magnetic poles of the two magnetic steels 91 facing the moving and static contacts are set to be the same; the other magnetic steel 91 in the three magnetic steels 91 is arranged on the outside of one side of the length of the moving reed, And it is in the position corresponding to another moving and static contact (left side), and the pole face of said another piece of magnet steel 91 (left side) is substantially perpendicular to the pole faces of said two pieces o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com