Weight measuring tire breaking device

A tire breaking and weighing technology, applied to measuring devices, instruments, roads, etc., can solve the problems of large road damage, road collapse, difficult vehicles, etc., and achieve the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

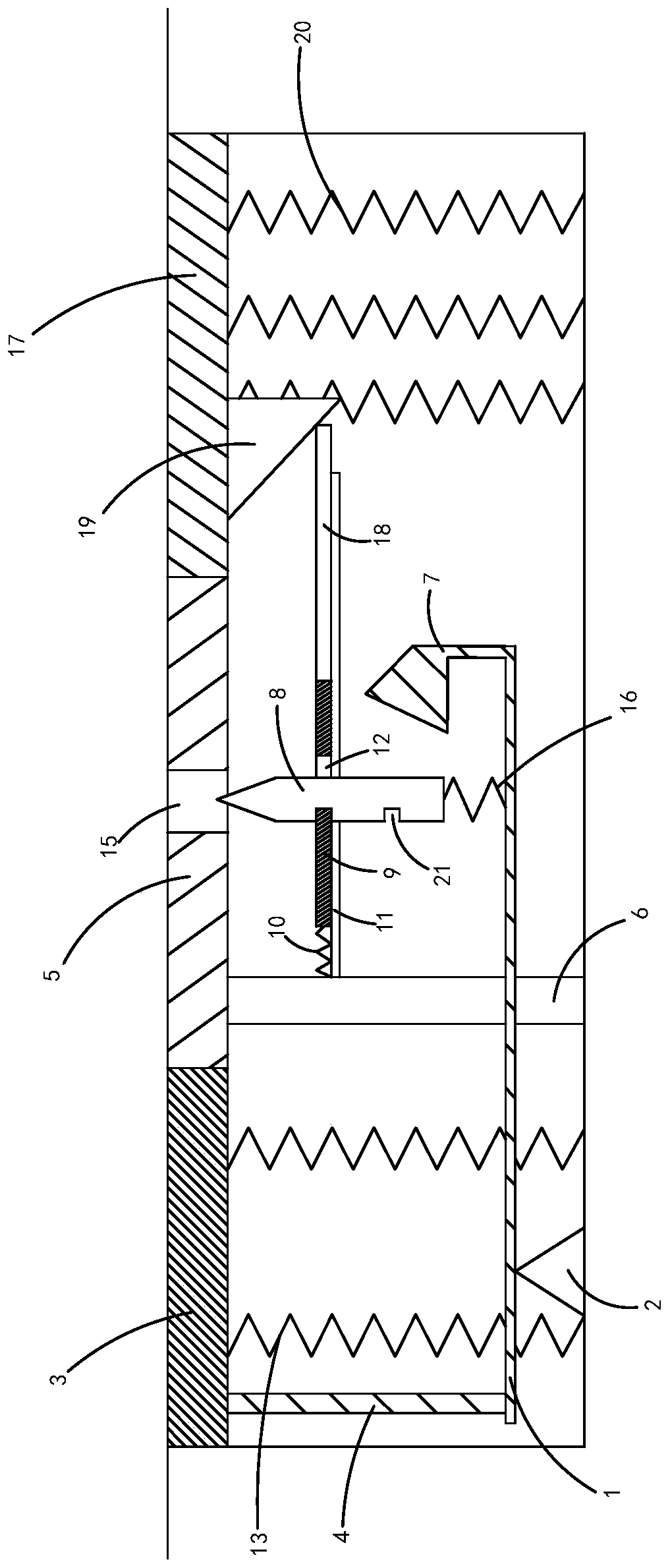

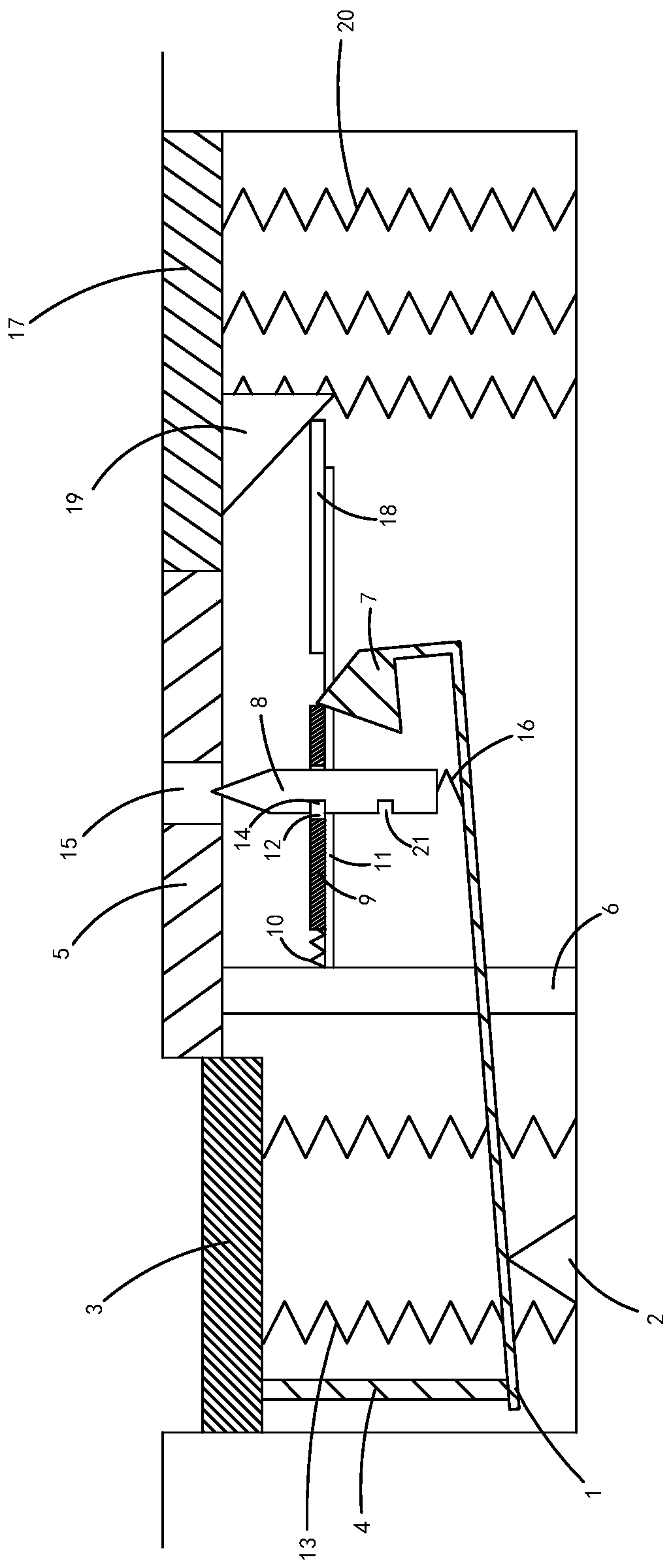

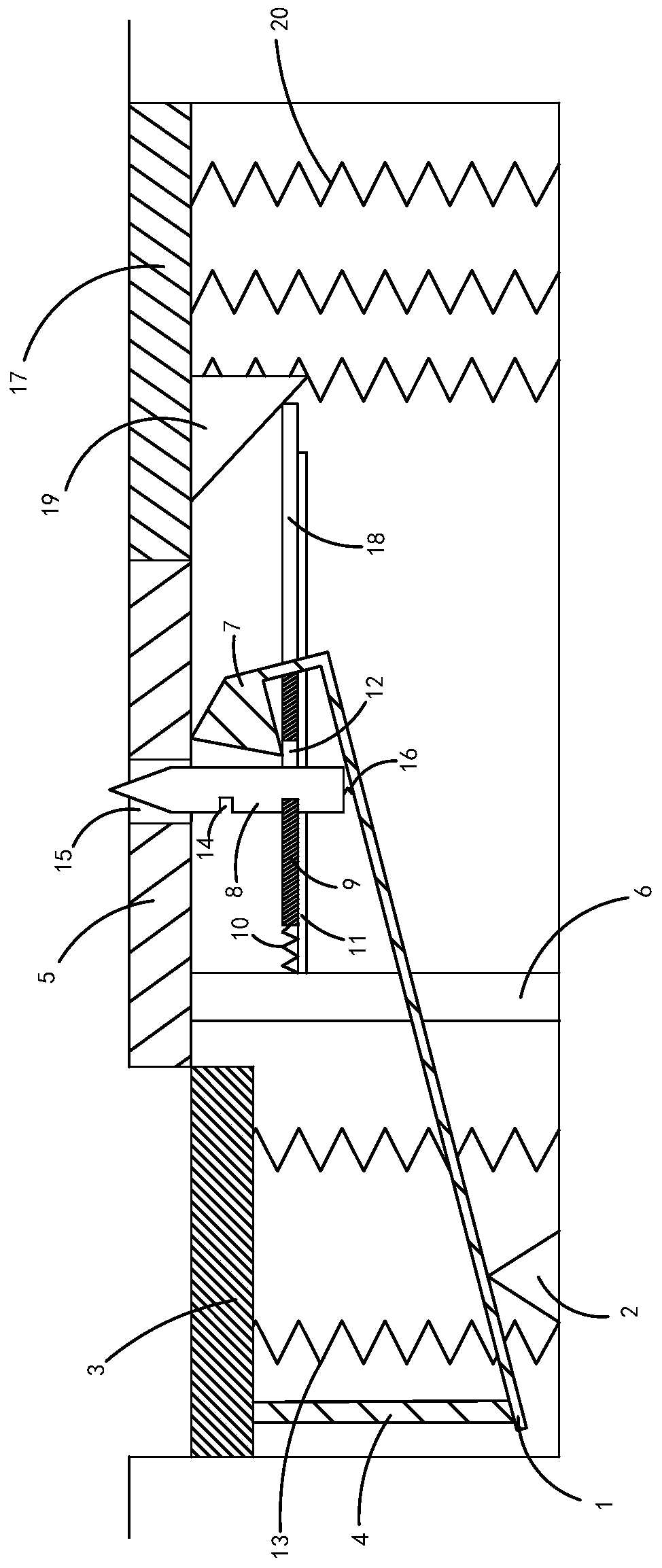

[0028] see Figure 1-4 , what this embodiment provides is a tire breaking device by weight measurement, including a lever plate 1, a fulcrum 2, a weight measuring plate 3, a lower pressure rod 4, a tire breaking plate 5, a first support plate 6, a starting needle 7, a tire breaking Needle 8, locking plate 9, locking spring 10, second support plate 11, first back-moving spring 13, broken tire spring 16, back-setting plate 17, reset push rod 18, reset wedge-shaped block 19 and second back-moving spring 20.

[0029] Wherein the road surface is sunken to form a pothole, and the ground at the bottom of the pothole is a horizontal plane, and the whole weighing tire breaking device is installed in the pothole, and the weight measuring plate 3, the tire breaking plate 5 and the resetting plate 17 are arranged from left to right along the vehicle traveling direction. To the right, it is arranged at the top opening of the pothole successively, and the weighing plate 3, the broken tire p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com