Printing method and printer capable of realizing small-batch high-speed printing

A high-speed printing, small-batch technology, applied in the direction of copying/marking, printing, object separation, etc., can solve the problems of unfavorable equipment utilization, equipment cost control, screen printing is not suitable for small batch printing, unfavorable equipment cost, etc. , to achieve the effect of low transmission control accuracy, good printing effect, and improved printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

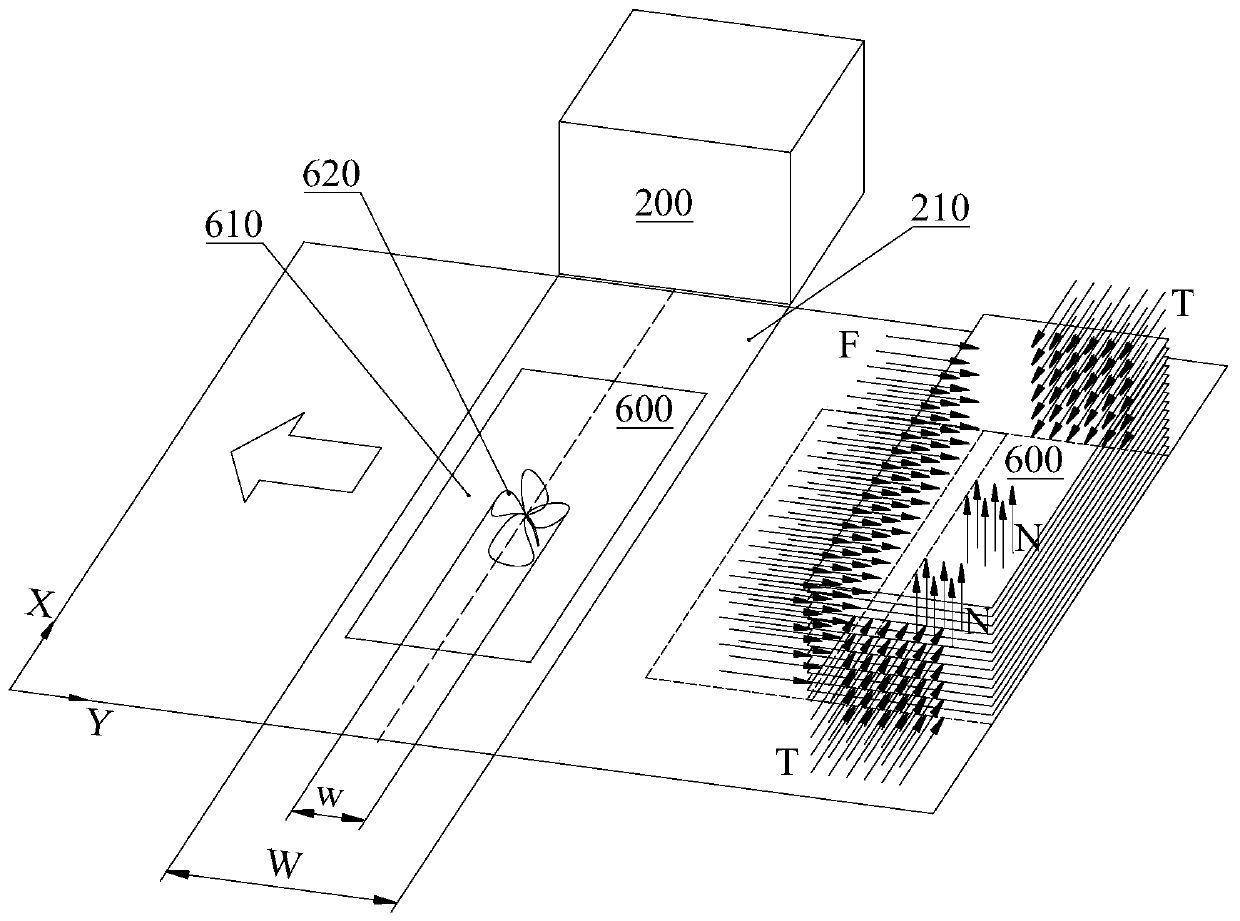

[0033] Such as figure 1 As shown, a small-batch high-speed printing printing method is used to print a target pattern 620 on a target area 610 of a discontinuous medium, including the following steps:

[0034] S1. Convey the medium along the Y direction to the position where the print format of the spray vehicle covers the target area 610 or the target area 610 covers the print format of the spray vehicle, and stop the transmission after reaching the position;

[0035] S2. The spray vehicle moves along the X direction, and prints the target pattern 620 on the target area 610 of the medium during the moving process;

[0036] Wherein, the Y direction and the X direction are perpendicular to each other, and the projected length w of the target pattern 620 in the Y direction is smaller than the projected length W of the inkjet print surface in the Y direction.

[0037] The present invention is different from the traditional multi-pass and single-pass printing modes, and creativel...

Embodiment 2

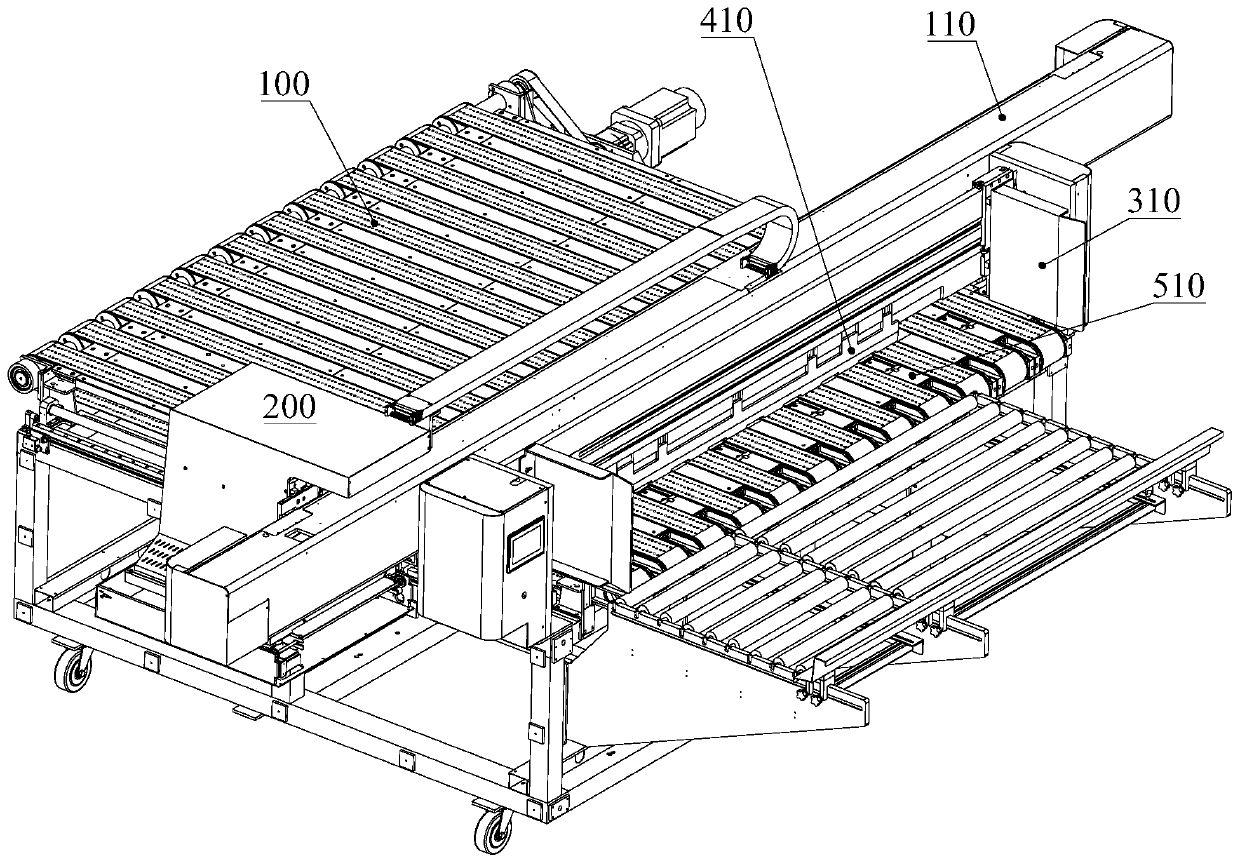

[0043] Such as figure 2 As shown, a small batch high-speed printing printer for printing target patterns on target areas of non-continuous media, including

[0044] The conveying platform 100 is used to convey the medium from the back to the front, and has a conveying direction Y; and

[0045] The spray vehicle is movably arranged above the conveying platform 100 and has a displacement direction X perpendicular to the conveying direction Y. The projected length W of the print format of the sprayed vehicle in the conveying direction Y is greater than the projected length of the target pattern in the conveying direction Y w;

[0046] Before printing, the conveying platform 100 conveys the medium to the position where the printing surface of the jetting vehicle covers the target area or the target area covers the printing width of the jetting vehicle, and the target pattern is printed after the medium is transported in place.

[0047] The present invention is different from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com