Tobacco leaf blending method

A tobacco leaf and blending technology, which is applied in the fields of tobacco, tobacco preparation, and application, can solve the problems of unbalanced quality distribution of tobacco leaf raw materials, many grades, and inability to meet the formulation requirements of cigarette enterprises for individualization, refinement, and homogenization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

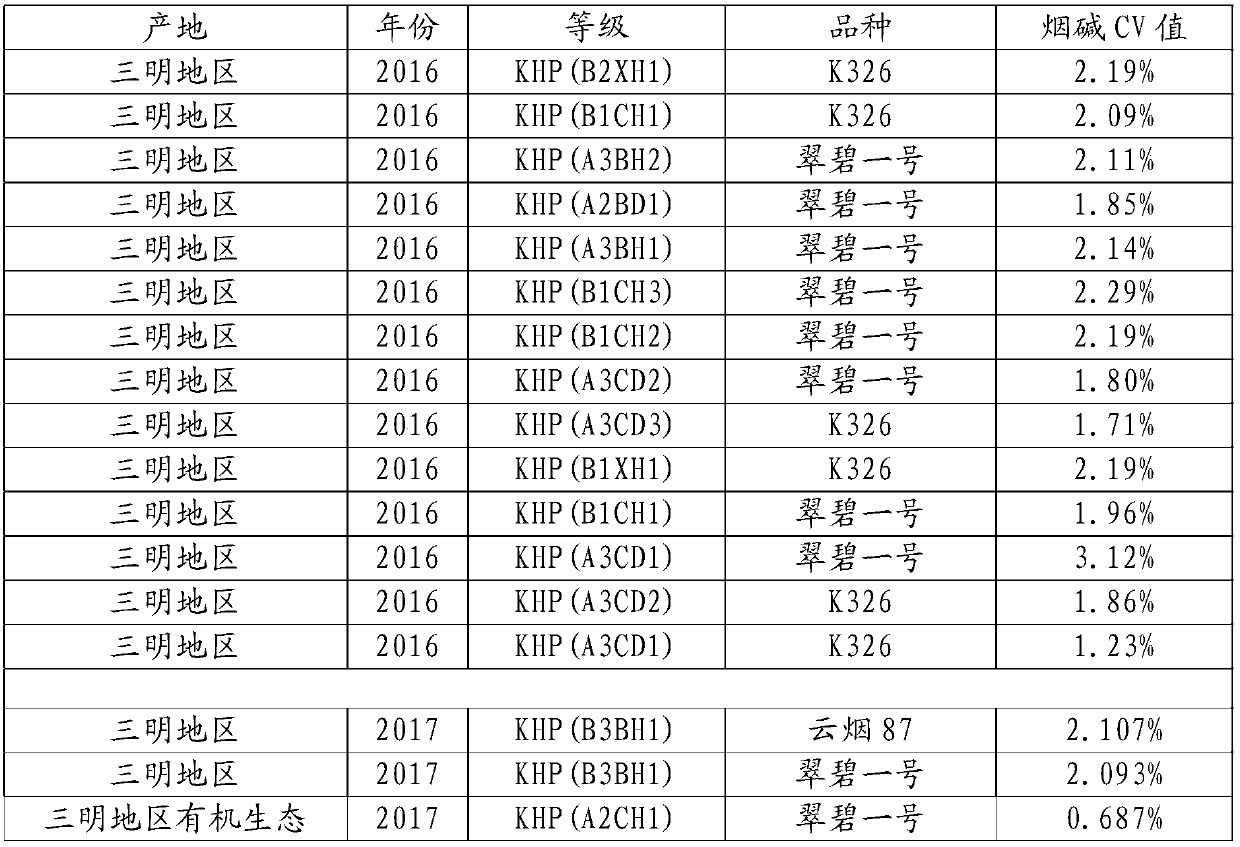

[0047] For two consecutive years in 2016 and 2017, a tobacco leaf mixing method provided by this application to improve the homogenization level of threshing and redrying was adopted in redrying factory A to process all modular tobacco leaves. The specific method is as follows:

[0048] 1. Storage and selection of raw tobacco

[0049] 1. Control of the selection process: According to the number of selected stations, they are divided into several groups, and each station in each group is assigned cigarette packs of different positions, and after selection, they are divided into small assembly boxes. After the selection of each table, the tobacco leaves are selected in pairs to ensure the selection quality.

[0050] 2. Tobacco leaves with a relatively large quantity of incoming materials are classified into grades and stacked according to the place of origin.

[0051] 3. Every 6 racks of tobacco leaves is a group, and each rack is marked with a label, and the group is marked o...

Embodiment 2

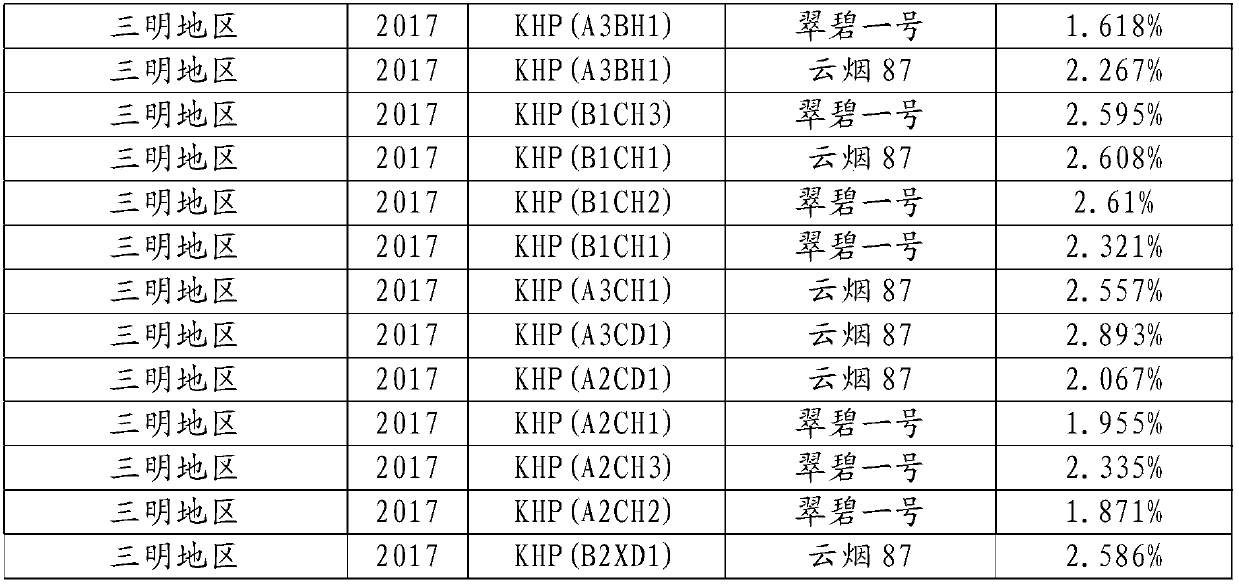

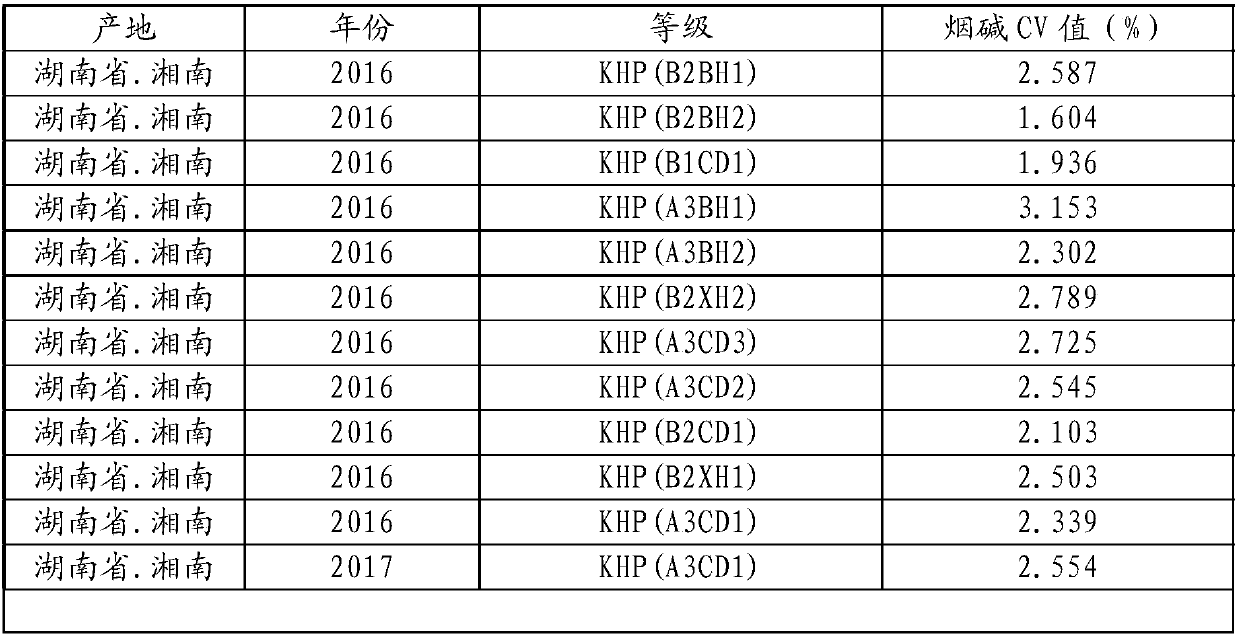

[0068] For two consecutive years in 2016 and 2017, a method of blending tobacco leaves to improve the homogenization level of threshing and redrying was adopted in the redrying factory B to process all the modular tobacco leaves of our company. The specific method is as follows:

[0069] 1. Storage and selection of raw tobacco

[0070] 1. Selection link control: According to the number of selection stations, divide them into several groups, each station in each group is allocated cigarette packs in different positions, and after selection, they are divided into small assembly boxes. After each stand is selected, the selected tobacco leaves are randomly inspected to ensure the selection quality.

[0071] 2. Tobacco leaves with a relatively large quantity of incoming materials are classified into grades and stacked according to the place of origin.

[0072] 3. Every 6 racks of tobacco leaves is a group, and each rack is marked with a label, and the group is marked on the logo....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com