Preparation method for fermented rice row noodles and fermented rice row noodles

A technology for rice and rice milk, which uses bacteria and food ingredients used in food preparation as taste improvers, lactobacilli, etc., can solve the problem of increasing the labor intensity of production work, difficulty in large-scale stable production, and affecting the surrounding environment of rice noodles. and other problems, to achieve the effect of good appearance, low cooking loss and broken rate, and high elasticity and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

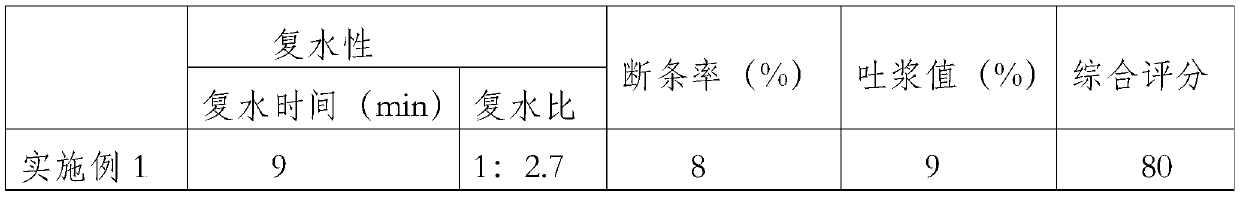

Embodiment 1

[0047] The invention provides a preparation method of fermented rice noodles:

[0048] (1) After mixing rice and water according to the mass ratio of 1:1, the mixture of rice and water is obtained, after heat preservation treatment at 25°C for 5 hours, heat preservation treatment at 35°C for 5 hours, and heat preservation treatment at 45°C for 5 hours, to obtain The mixture of rice and water after heat preservation treatment;

[0049] (2) Add lactic acid to the mixture of heat-preserved rice and water, adjust the pH to 4.5, then add lactic acid bacteria (Lactobacillus brevis ATCC 367 Lactobacillus brevis, the mass ratio of the added amount to the rice is 0.1‰), at 45°C After fermentation for 2 hours, the rice was cleaned and refined, and the obtained rice milk was subjected to plate-and-frame pressure filtration, washed with water for 2 to 3 times to obtain a filter cake, and dried (boiler pressure was 0.6 MPa, primary air intake was 135°C, The secondary air intake is 110°C, ...

Embodiment 2

[0053] The invention provides a preparation method of fermented rice noodles:

[0054] (1) After mixing rice and water according to the mass ratio of 1:1.5, the mixture of rice and water is obtained, after heat preservation treatment at 30°C for 3 hours, heat preservation treatment at 40°C for 3 hours, and then heat preservation treatment at 45°C for 3 hours to obtain The mixture of rice and water after heat preservation treatment;

[0055] (2) Add lactic acid to the mixture of rice and water after heat preservation treatment, adjust the pH to 5.0, add lactic acid bacteria (Lactobacillus casei ATCC 334 Lactobacillus casei, the mass ratio of the added amount to rice is 0.2‰), and the temperature is 50°C After 4 hours of fermentation, the rice was cleaned and refined, and the obtained rice milk was subjected to plate-and-frame press filtration, washed with water for 2 to 3 times to obtain a filter cake, and dried (boiler pressure was 0.6 MPa, primary air intake was 135°C, The s...

Embodiment 3

[0059] The invention provides a preparation method of fermented rice noodles:

[0060] (1) After mixing rice and water according to the mass ratio of 1:1.5, the mixture of rice and water was obtained. After heat preservation treatment at 28°C for 3 hours, heat preservation treatment at 35°C for 3 hours, and heat preservation treatment at 45°C for 3 hours, obtained The mixture of rice and water after heat preservation treatment;

[0061] (2) Add lactic acid to the mixture of heat preservation treated rice and water, adjust the pH to 4.8, add lactic acid bacteria Lactobacillus gasseri ATCC 33323 Lactobacillus gasseri, the mass ratio of the added amount to rice is 0.15‰), at 50°C After lower fermentation for 3 hours, the rice was cleaned and refined, and the obtained rice milk was subjected to plate and frame pressure filtration, washed with water for 2 to 3 times to obtain a filter cake, and dried (boiler pressure was 0.6 MPa, primary air intake was 135°C, The secondary air int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com