Tunnel communication repeater

A technology of repeaters and tunnels, which is applied in the direction of radio transmission systems, electrical components, transmission systems, etc., can solve problems such as the loss of protection of the dust-proof net, the influence of the normal operation of the repeater, and the entry of dust, so as to avoid normal heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

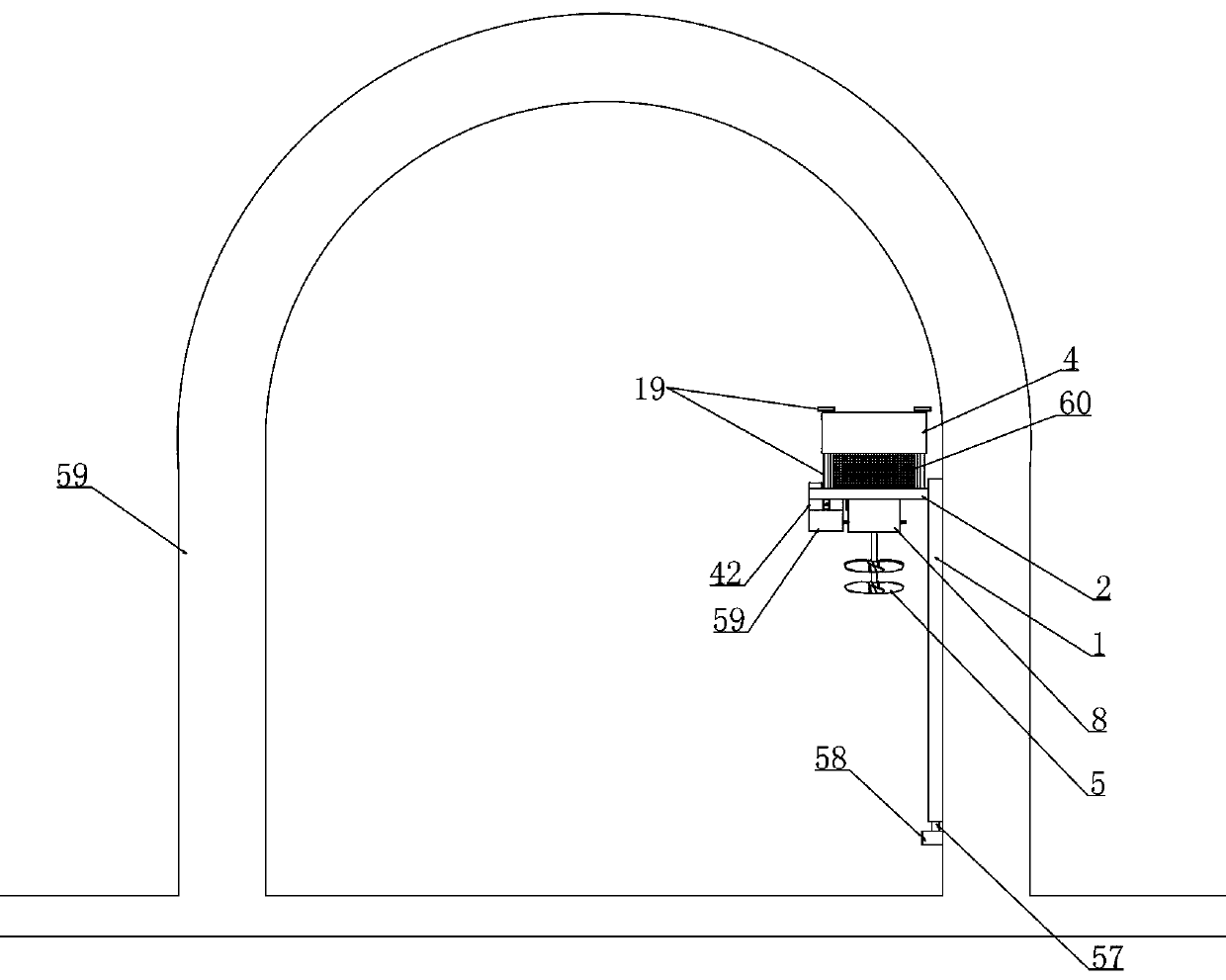

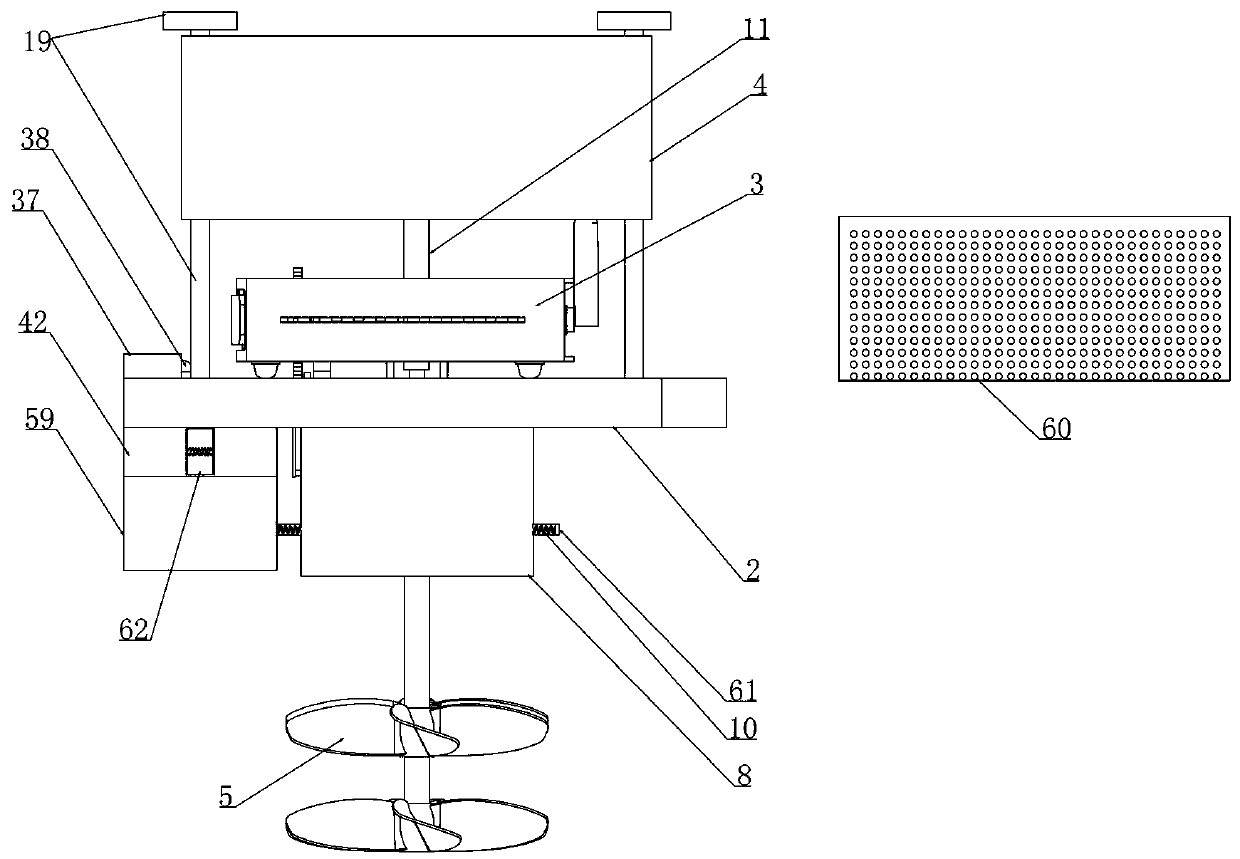

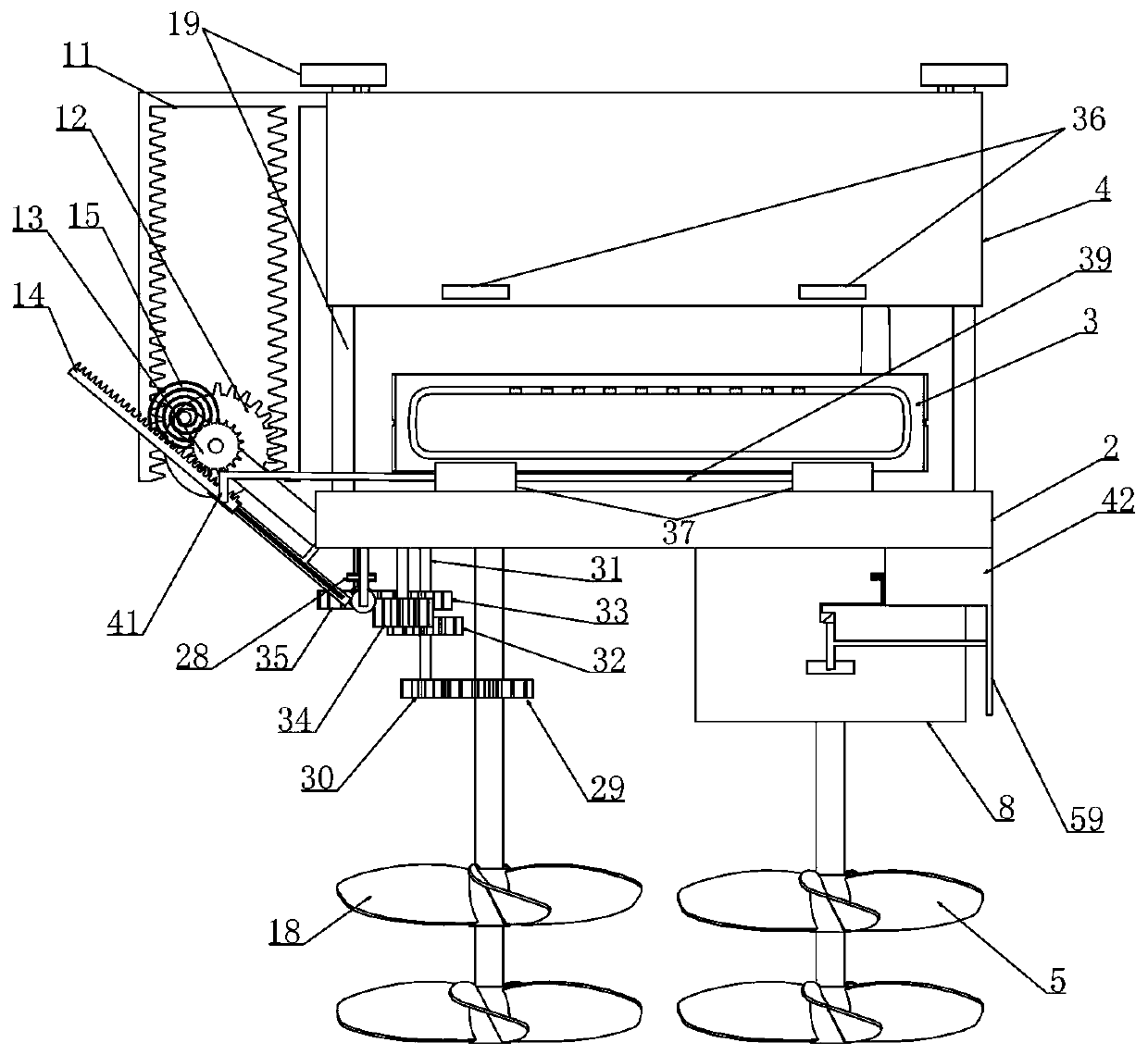

[0048] Embodiment 1, this embodiment provides a tunnel communication repeater, refer to the attached figure 1 As shown, it includes a slideway 1 fixedly installed on the side wall of the tunnel and a bearing plate 2 is vertically slidably installed in the slideway 1, and a communication host 3 is fixedly installed on the bearing plate 2. We control the bearing plate 2 in the sliding Vertically move in the channel 1, and then drive the communication host 3 to move vertically. When the communication host 3 needs to be inspected and maintained, the communication host 3 will be moved down to facilitate maintenance personnel to perform inspection and maintenance operations on it. The bottom of the bearing plate 2 is provided with an outlet (not shown in the figure), and the data line connected to the communication host 3 protrudes outward through the outlet. It is characterized in that we vertically slide and install a protective The cover 4 and the carrier plate 2 are provided wit...

Embodiment 2

[0055]Embodiment 2, on the basis of embodiment 1, with reference to appended Figure 8 As shown, four guide columns 19 are fixed on the upper end surface of the bearing plate 2 and the protective cover 4 is vertically slidably installed on the four guide columns 19, referring to the attached Figure 10 As shown, when the positioning device realizes the positioning of the protective cover 4, the L-shaped rod 20 is inserted into the L-shaped hole 22 that cooperates with it and is arranged on the protective cover 4, as attached Figure 10 As shown, when several trigger balls 7 are in contact with the arc-shaped trigger plate 9, the L-shaped bar 20 is moved toward the direction of the compression positioning spring 21 and the horizontal part of the L-shaped bar 20 is withdrawn from the horizontal part of the L-shaped hole 22, Now protective cover 4 loses the location of L-shaped bar 20 to it, then protective cover 4 moves down along guide bar under its own gravity, thereby realize...

Embodiment 3

[0056] Embodiment 3, on the basis of Embodiment 2, in this solution, four trigger balls 7 are arranged in total and correspond to four guide columns 19 respectively, and the two arc-shaped trigger plates 9 do not contact in the initial state (as shown in the attached Figure 11 As shown), we connect the L-shaped rod 20 with the positioning spring 21 and fix the iron plate on the side wall, refer to the attached Figure 12 As shown, when the air in the tunnel is static, that is, when the high-speed train is not passed, some trigger balls 7 are not in contact with the arc trigger plate 9, when the high-speed train is passed in the tunnel, the high-speed airflow generated drives the trigger fan blade 5 to rotate and Synchronously drive a number of bearing rods 23 fixed on the outer wall of the ring 6 to rotate, and then throw the trigger ball 7 fixedly mounted on the swing rod 24 outward through centrifugal force so that the trigger ball 7 touches the inner circle of the arc-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com