Graphene lead-carbon battery negative electrode plaster board and preparation method thereof

A lead-carbon battery and negative electrode paste technology, which is applied in the field of electrochemical power sources, can solve the problems of battery negative plate volume expansion, low charge acceptance, and battery negative plate cracks, etc., to improve quality stability and broad market application prospects , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

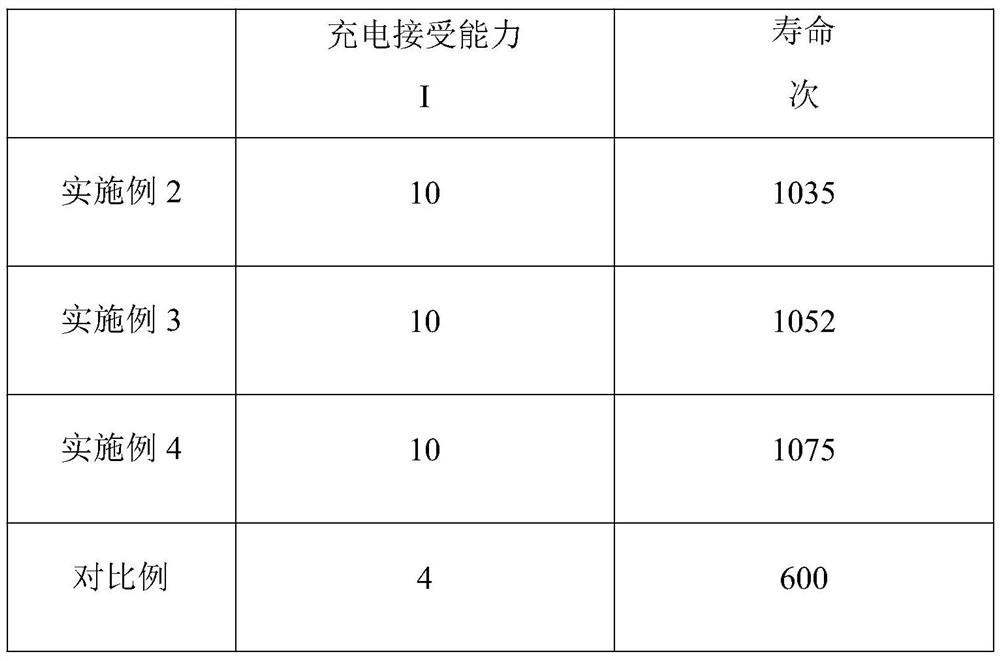

Examples

Embodiment 1

[0068] A graphene lead-carbon battery negative electrode plaster board, its raw materials include by mass percentage:

[0069] Graphene 0.3~0.5%,

[0070] Lignin 6-10%,

[0071] Crude wood fiber 0.55~0.65%,

[0072] Polyester fiber 0.2~0.6%,

[0073] Water-based acrylic resin 1~6%,

[0074] Curing agent 0.1~0.6%,

[0075] Carbon nanotubes and carboxylated double-walled carbon nanotubes 0.11~0.14%,

[0076] Indium trioxide 0.01~0.03%,

[0077] Dispersant 0.2~1%,

[0078] Water 10~15%,

[0079] The rest is lead sponge, and the mass percentage sum of all raw materials is 100%;

[0080] The graphene is a graphene nano-chip.

[0081] Preferably, the raw materials of the graphene lead-carbon battery negative electrode plaster board include by mass percentage:

[0082] Graphene 0.4%,

[0083] Lignin 8%,

[0084] Crude wood fiber 0.6%,

[0085] Polyester 0.4%,

[0086] Water-based acrylic resin 3.5%,

[0087] Curing agent 0.35%,

[0088] Carbon nanotubes and carboxylat...

Embodiment 2

[0105] A graphene lead-carbon battery negative electrode plaster board, its raw materials include by mass percentage:

[0106] Graphene 0.3%,

[0107] Lignin 6%,

[0108] Crude wood fiber 0.55%,

[0109] Polyester 0.2%,

[0110] Water-based acrylic resin 1%,

[0111] Curing agent 0.1%,

[0112] Carbon nanotubes and carboxylated double-walled carbon nanotubes 0.11%,

[0113] Indium trioxide 0.01%,

[0114] Dispersant 0.2%,

[0115] water 10%,

[0116]The rest is lead sponge, and the mass percentage sum of all raw materials is 100%;

[0117] The graphene is a graphene nano-chip.

[0118] In this embodiment, the carbon nanotubes are a mixture of single-walled carbon nanotubes and double-walled carbon nanotubes.

[0119] In this embodiment, the carbon nanotubes are a mixture of single-wall carbon nanotubes and double-wall carbon nanotubes. The mass ratio of single-wall carbon nanotubes and double-wall carbon nanotubes is 1:0.65.

[0120] In this embodiment, the dispersa...

Embodiment 3

[0128] A graphene lead-carbon battery negative electrode plaster board, its raw materials include by mass percentage:

[0129] Graphene 0.5%,

[0130] Lignin 10%,

[0131] Crude wood fiber 0.65%,

[0132] Polyester 0.6%,

[0133] Water-based acrylic resin 6%,

[0134] Curing agent 0.6%,

[0135] Carbon nanotubes and carboxylated double-walled carbon nanotubes 0.14%,

[0136] Indium trioxide 0.03%,

[0137] Dispersant 1%,

[0138] Water 15%,

[0139] The rest is lead sponge, and the mass percentage sum of all raw materials is 100%;

[0140] The graphene is a graphene nano-chip.

[0141] In this embodiment, the carbon nanotubes are a mixture of single-walled carbon nanotubes and double-walled carbon nanotubes.

[0142] In this embodiment, the carbon nanotubes are a mixture of single-wall carbon nanotubes and double-wall carbon nanotubes. The mass ratio of single-wall carbon nanotubes and double-wall carbon nanotubes is 1:0.78.

[0143] In this embodiment, the dispersa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com