Fan blade lattice tester and method for changing flow inlet angle of fan blade lattice

A cascade test, fan-shaped technology, applied in the direction of machine/engine, stator, engine components, etc., can solve problems such as poor technical feasibility, and achieve the effect of reducing materials, facilitating changes, and shortening experimental preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

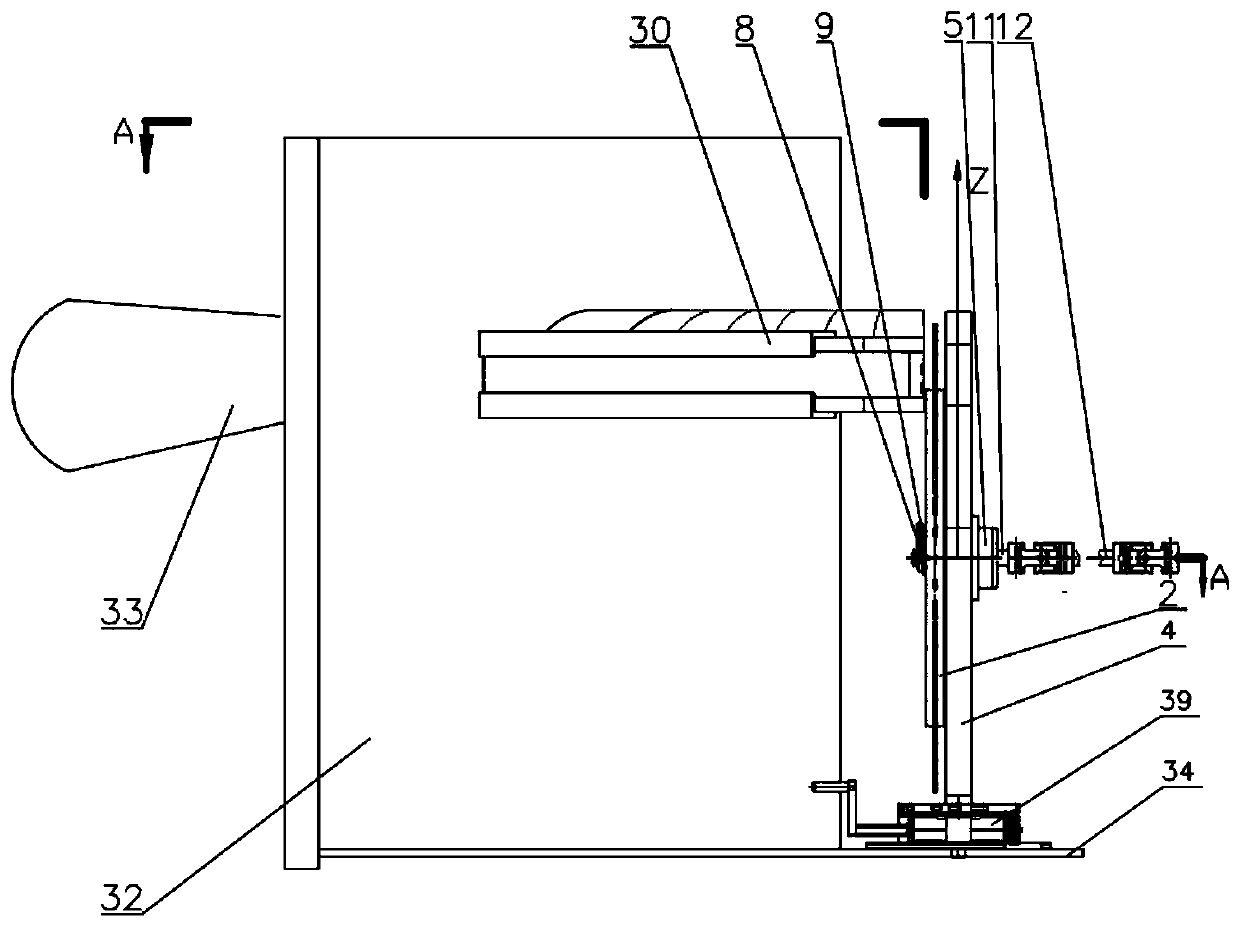

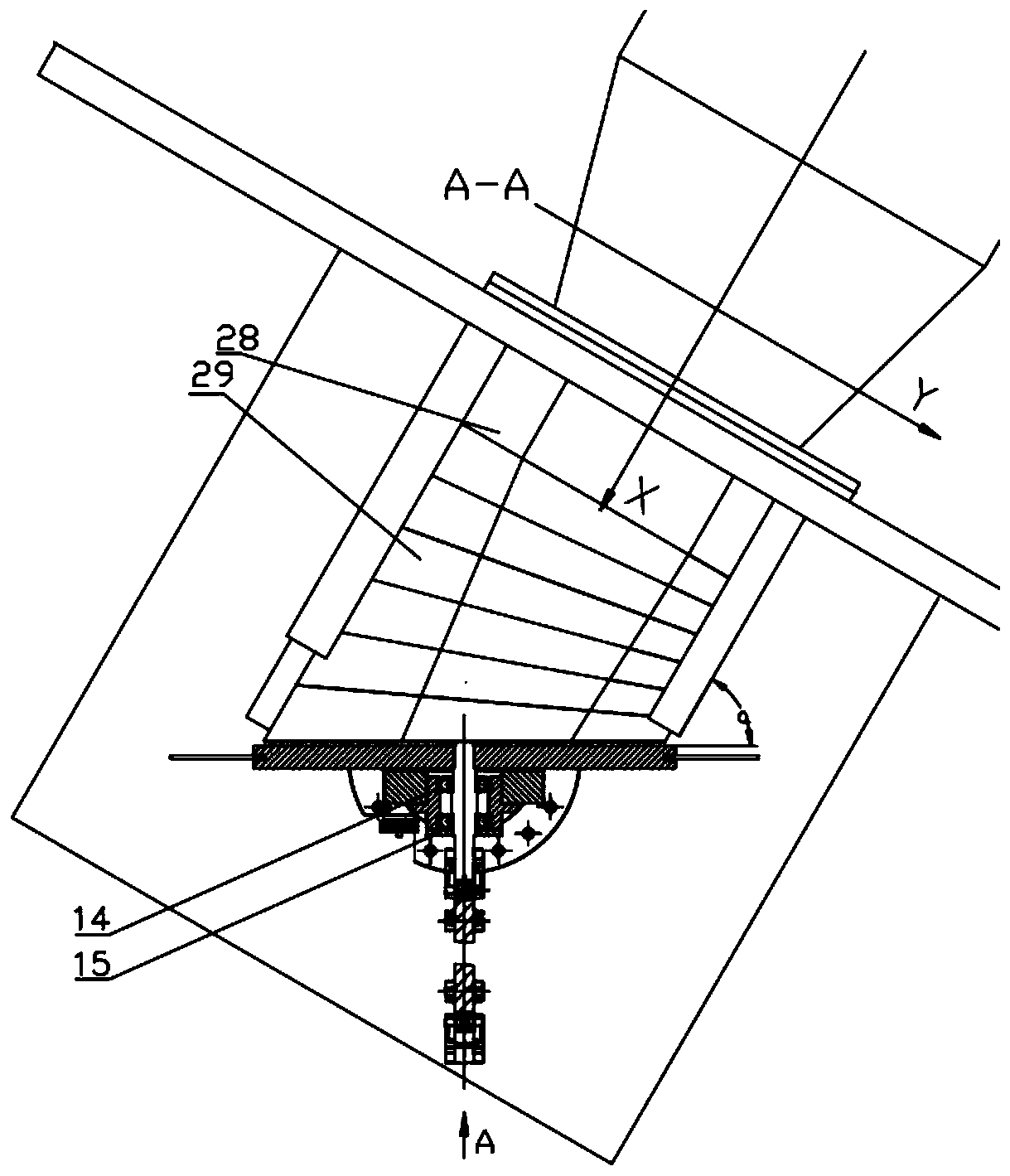

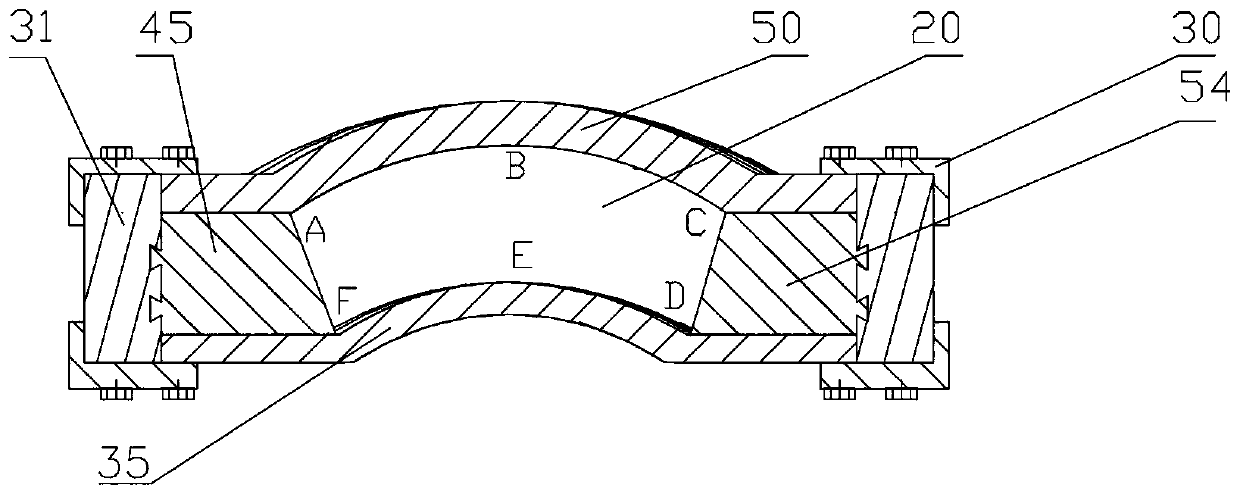

[0116] Such as figure 1 , 2 , 3 and 17, the present invention proposes a fan-shaped cascade tester, at least including a fan-shaped cascade 25 simulating an engine turbine and an experimental section 20 upstream thereof, and a simulated stator disc for simulating a vane can be arranged between the two 2. There may be a pressure vessel chamber 40 containing them outside the above-mentioned components. The fan-shaped turbine cascade 25 is coaxial with the simulated stator disk 2, and the axis can swing within a certain angle range, forming a different air intake angle a with the outlet of the experimental section. For this reason, the experimental section includes replaceable building blocks, such as the inner surface The arched upper curved surface is formed by splicing oblique building blocks 29 and straight building blocks 28 etc., and the entrance and exit surfaces of the oblique building blocks 29 etc. have different hypotenuses so that the end of the flow channel and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com