Large-span composite structure type underground station and construction method thereof

A composite structure and underground station technology, applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of pedestrian traffic, troublesome construction of intermediate structural columns, and difficult to guarantee construction quality, saving time and cost. , the effect of speeding up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

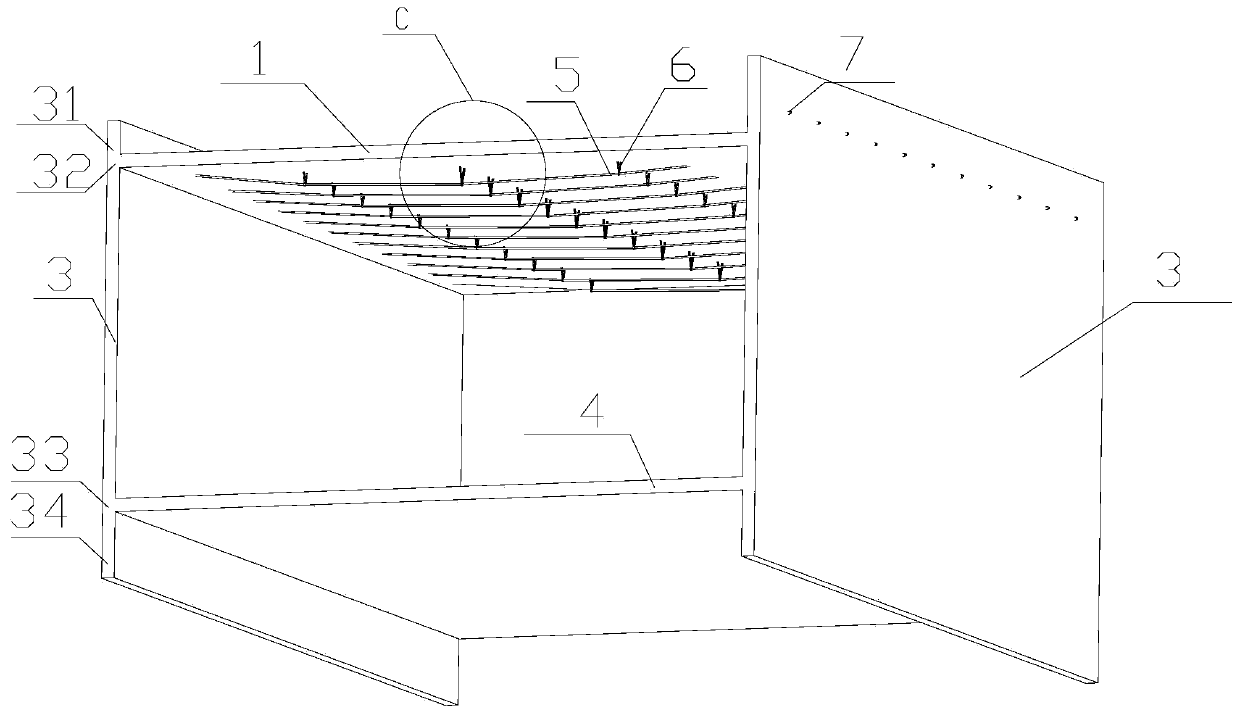

[0029] Such as Figure 1-4 As shown, a large-span composite structure underground station includes a top floor, a side wall and a floor, and the top floor, the top floor and two side walls are arranged in the shape of a "mouth".

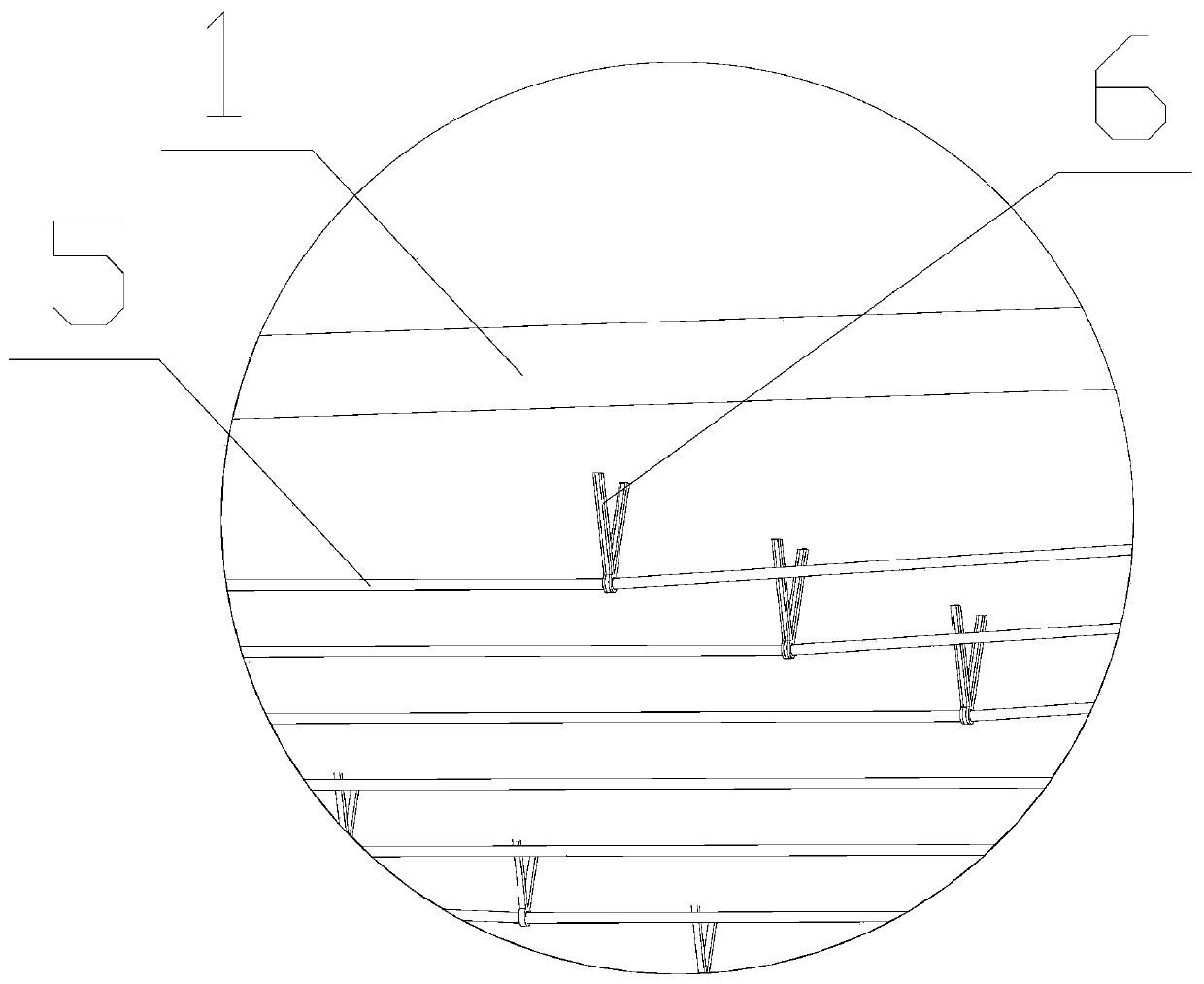

[0030] The top layer includes a top plate, a first stay cable, a second stay cable and a connecting rod, and a row of fixed points extending along the driving direction of the station is arranged on both sides of the middle of the top plate, and each fixed point in the row of fixed points In one-to-one correspondence with the fixing points of the other row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com