High-speed paper machine, cationic starch and preparation method of cationic starch

A technology of cationic starch and cationic etherifying agent, applied in paper, papermaking, paper coating and other directions, can solve the problems of hindering fiber bonding, unable to improve the bonding strength between paper layers, and low degree of gelatinization, so as to reduce the gelatinization temperature, The effect of improving the degree of product substitution and improving the degree of gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

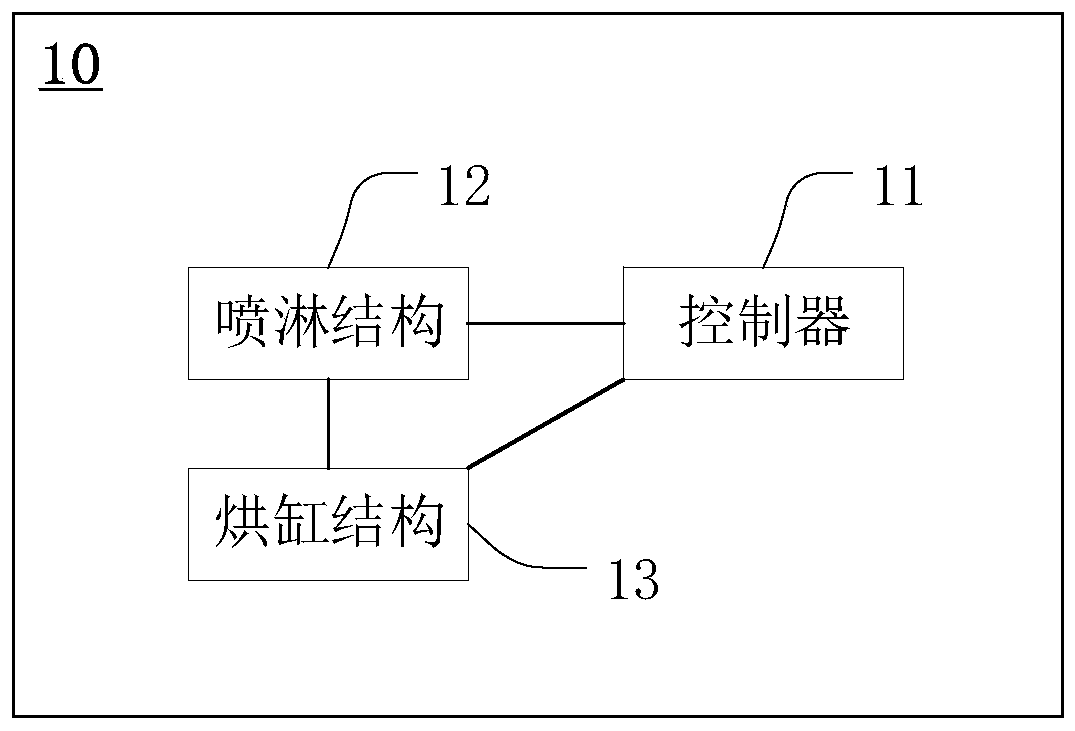

Method used

Image

Examples

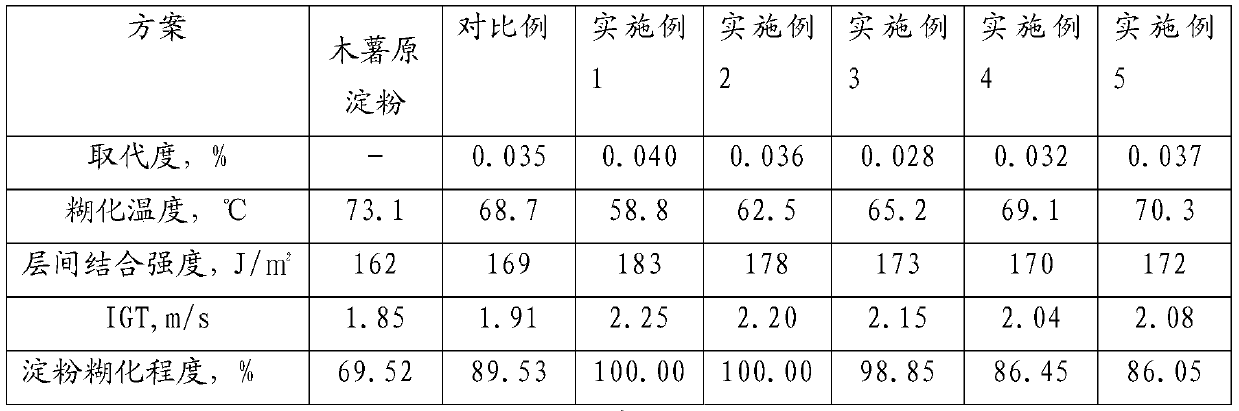

Embodiment 1

[0062] Adding a certain amount of cassava starch to a certain amount of water to prepare a concentration of 40% raw starch slurry, then adding a quality to the raw starch slurry is 0.7% of the absolute dry raw starch quality, and the concentration is 10% of the first alkali catalyst sodium hydroxide solution , and stirred evenly with the rotating speed of 1000rpm / min, now the pH of the raw starch slurry through alkali treatment is 10.94, and then adding the cationic etherifying agent that quality is 7% dry raw starch quality and quality is dry raw starch slurry to raw starch slurry 1.3% of the starch mass, the concentration is the mixed solution of the second alkali catalyst sodium hydroxide solution of 10%, the stirring speed is adjusted to 100rpm / min, the etherification reaction temperature is maintained at 40°C, and the reaction is carried out for 8 hours to prepare the cationic starch .

Embodiment 2

[0064] Adding a certain amount of tapioca starch to a certain amount of water to prepare a concentration of 42% raw starch slurry, then adding a quality to the raw starch slurry is 0.6% of the absolute dry raw starch quality, and the concentration is 10% of the first alkali catalyst sodium hydroxide solution , and stir evenly with the rotating speed of 1000rpm / min, now the pH of the raw starch slurry through alkali treatment is 10.56, then add the cationic etherification agent that quality is 6% dry raw starch quality and quality is dry raw starch slurry to raw starch slurry 1.2% of the starch mass, the concentration is the mixed solution of the second alkali catalyst sodium hydroxide solution of 10%, the stirring speed is adjusted to 100rpm / min, the etherification reaction temperature is maintained at 40°C, and the reaction is carried out for 10 hours to prepare the cationic starch .

Embodiment 3

[0066] Adding a certain amount of cassava starch to a certain amount of water to prepare a concentration of 38% raw starch slurry, then adding a quality to the raw starch slurry is 0.7% of the absolute dry raw starch quality, and the concentration is 10% of the first alkali catalyst sodium hydroxide solution , and stir evenly with the rotating speed of 1000rpm / min, now the pH of the raw starch slurry through alkali treatment is 10.71, then add the cationic etherification agent that quality is 5% dry raw starch quality and quality is dry raw starch slurry to raw starch slurry 1.0% of the starch mass, the concentration is a mixed solution of the second alkali catalyst sodium hydroxide solution of 10%, the stirring speed is adjusted to 100rpm / min, the etherification reaction temperature is maintained at 40°C, and the reaction is carried out for 12 hours to prepare cationic starch .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com