Automatic feeding device for valve seat ring

A technology of automatic feeding and valve seat ring, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of low feeding efficiency, high jam rate, complex structure, etc., to reduce the jam rate and simple structure. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention are described with reference to the above drawings.

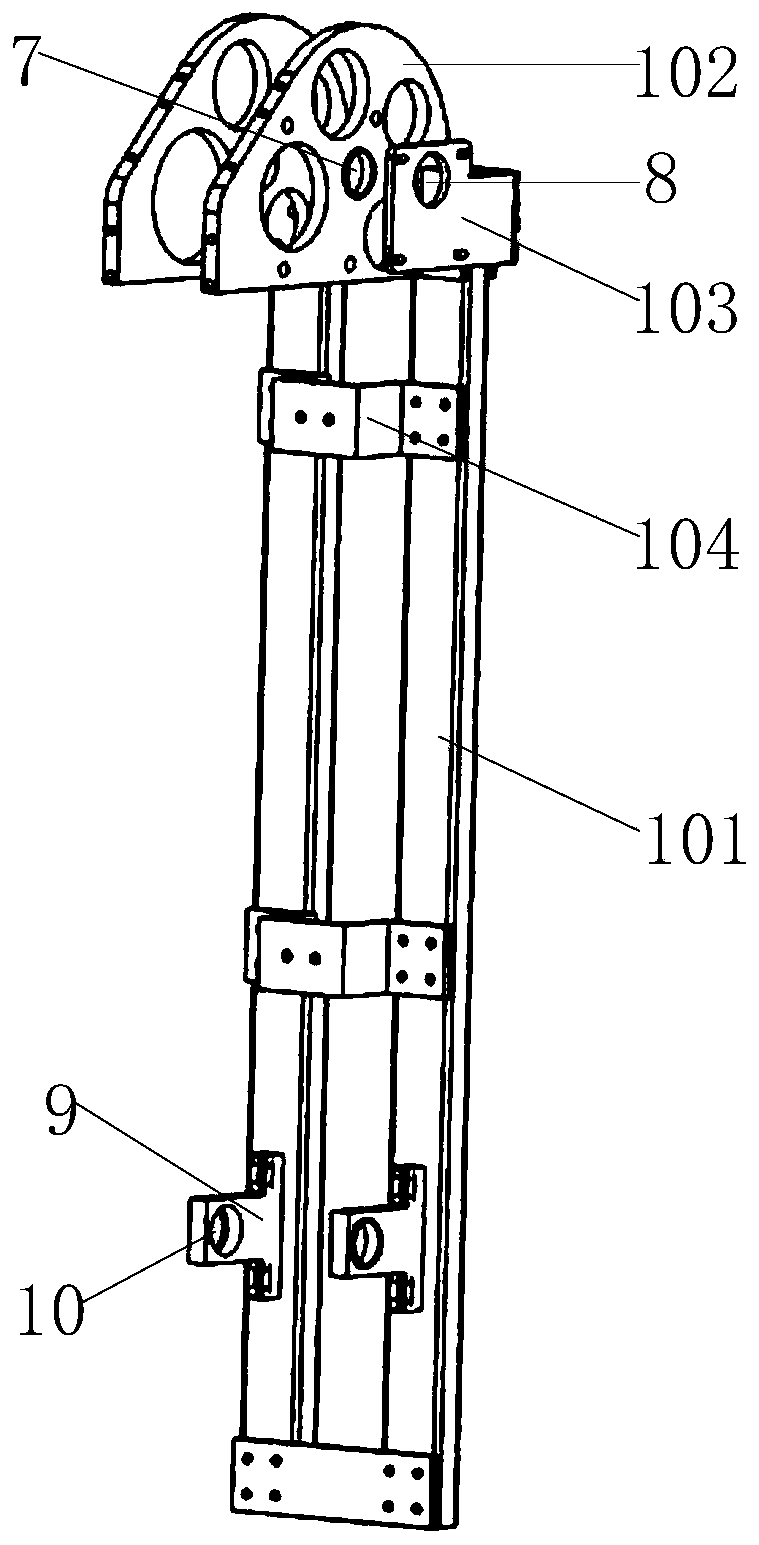

[0022] like Figure 1-5 As shown, a valve seat automatic feeding device in this embodiment includes a support mechanism 1, a transmission mechanism 2 is provided on one side of the support mechanism 1, a drive mechanism 3 for driving the transmission mechanism 2 and a setting In the actuator 4 on the transmission mechanism 2, the other side of the support mechanism 1 is provided with a material storage box 5, and a gap 6 is provided on the side of the storage box 5 and close to the support mechanism 1, so that The actuator 4 includes a bottom plate 41 arranged on the transmission mechanism 2 and a material hook 42 connected to the bottom plate 41 . That is to say, in this embodiment, the actuator 4 has multiple groups, and the angle formed between the material hook 42 and the bottom plate 41 is 60°, which is convenient for hooking the seat ring; the material hook 42 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com