7-shaped rolling type mop

A rolling, font-shaped technology, used in carpet cleaning, floor cleaning, cleaning equipment, etc., can solve problems such as high cost and unfavorable hand hygiene, and achieve the effect of fewer manufacturing processes, light and clean mopping, and low material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

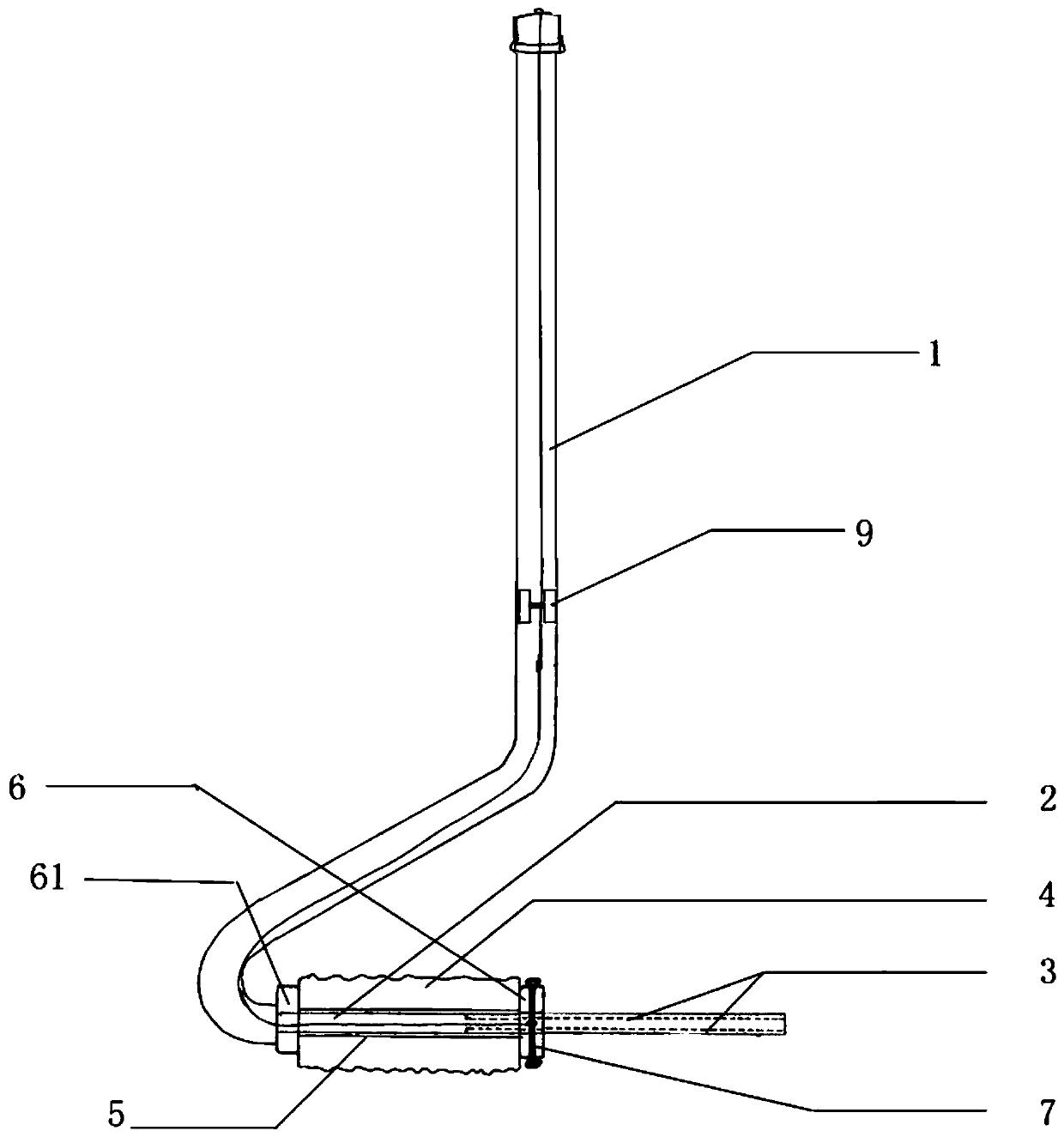

[0032] As shown in 1, this embodiment discloses a 7-shaped rolling mop, which includes a mop rod composed of a straight rod 1 and a horizontal rod 2, a mop head arranged on the horizontal rod 2, a pull cord 8, and the inside of the mop rod Hollow, the lower end of the straight bar 1 communicates with the left end of the cross bar 2 . The mop head includes a strip-shaped elastic cleaning body 4 , a first clip 6 and a movable shaft 7 , and the first clip 6 is arranged on the right side of the cross bar 2 . The mop head includes a strip-shaped elastic cleaning body 4, a first clip 6 and a movable shaft 7. The symmetrical two walls of the cross bar 2 are provided with through slots 3, and the elastic cleaning body 4 is opened along the length direction. There is an installation hole 5, which is sleeved on the cross bar 2 through the installation hole 5. The diameter of the installation hole 5 is larger than the outer diameter of the cross bar 2; the movable shaft 7 is installed al...

Embodiment 2

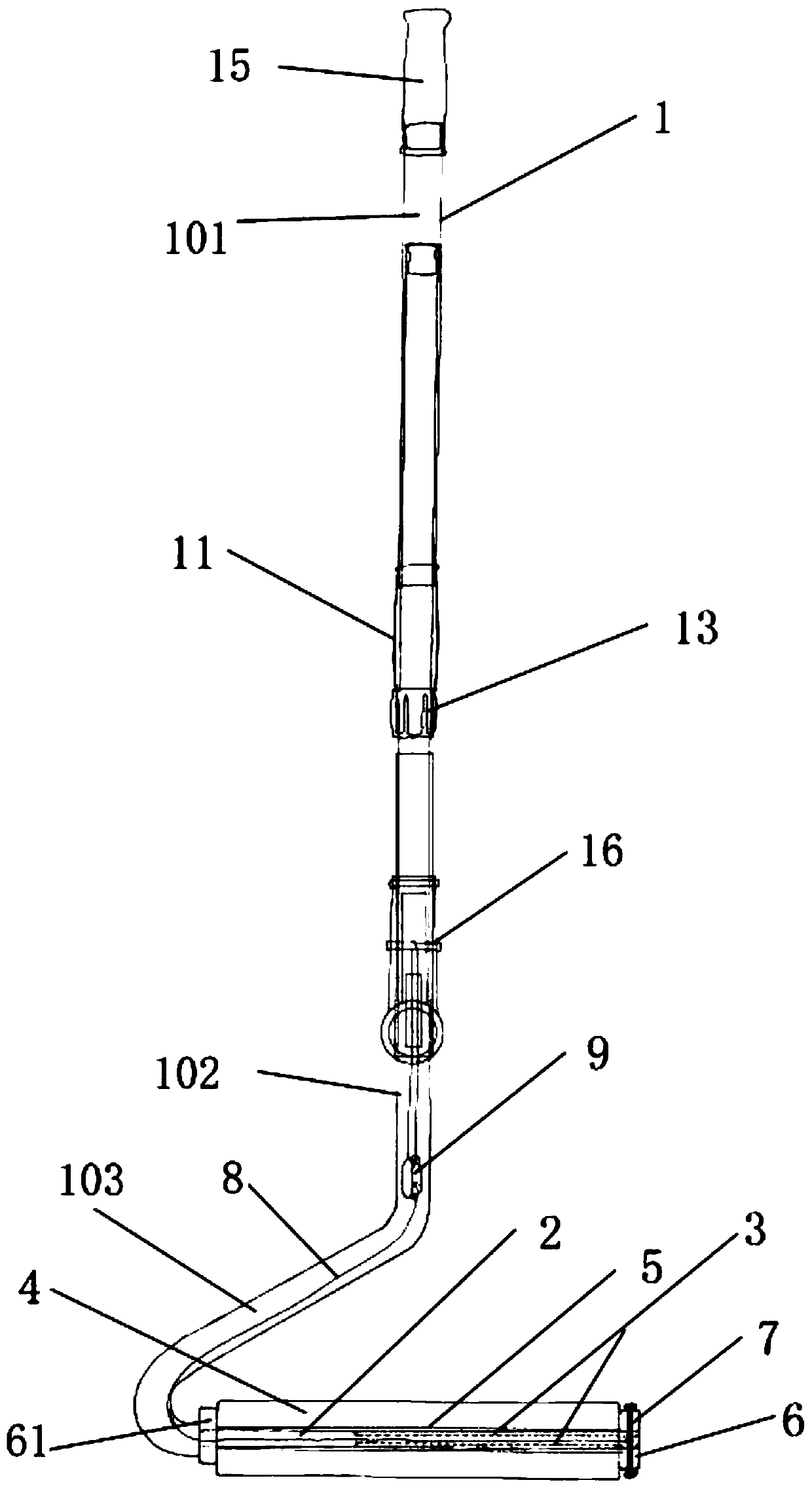

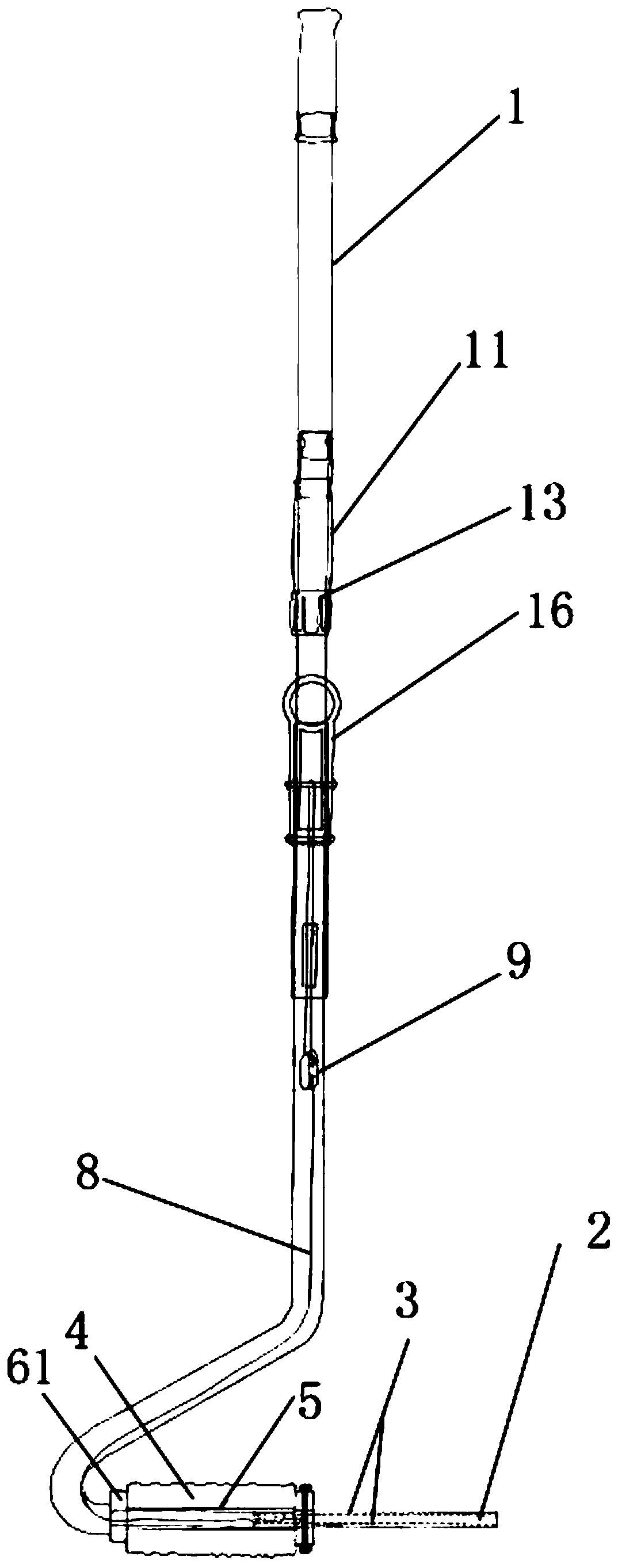

[0037] Different from Example 1, as Figure 2-3 As shown, the stay cord 8 protrudes from the side wall of the straight bar 1. When the moisture on the mop head needs to be wrung out, the user pulls the stay cord 8 upwards from the side of the mop to move the elastic cleaning body on the cross bar in 4 directions. Compression on the left.

[0038] A preferred embodiment is that a movable handle 16 is sheathed on the straight rod 1 , the movable handle 16 is slidably connected with the straight rod 1 , and the other end of the drawstring 8 is fixed on the movable handle 16 . By pulling the wrench upwards, the pull cord is driven to pull the movable shaft to the left, thereby compressing the elastic cleaning body of the mop head to achieve the purpose of dehydration.

[0039] The straight rod 1 of this embodiment can be a telescopic rod. An embodiment of a telescopic rod structure is that the straight rod 1 is composed of an upper rod 101, a lower rod 102, and an oblique rod 10...

Embodiment 3

[0045] Such as Figure 4 with 5 As shown, this embodiment discloses a roller mop, which includes a mop rod and a mop head located at the lower end of the mop rod, and also includes a pull cord. The inside of the mop rod is hollow and includes a straight rod 1 and a horizontal rod 2. One end of the straight bar 1 communicates with one end of the cross bar 2, the pull cord is placed inside the mop bar and the two ends are respectively located in the straight bar 1 and the cross bar 2;

[0046] The mop head includes a strip-shaped elastic cleaning body 4, a first clip 6 and a movable shaft 7. The symmetrical two walls of the crossbar 2 are provided with through slots 3, and the elastic cleaning body 4 is along the length direction There is an installation hole 5, which is sleeved on the cross bar 2 through the installation hole 5. The diameter of the installation hole 5 is larger than the outer diameter of the cross bar 2; the movable shaft 7 is installed along the radial direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com