Seed-carrying combined drip irrigation band and manufacturing method thereof

A production method and technology of drip irrigation tape, applied in botany equipment and method, pressurized spreading method of liquid fertilizer, sowing seeder, etc., can solve the problem of increasing the workload of seedlings during the period, increasing the cost of agricultural planting, affecting the yield, etc. problems, to achieve the effect of reducing the difficulty of field operations, increasing germination rate and crop yield, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

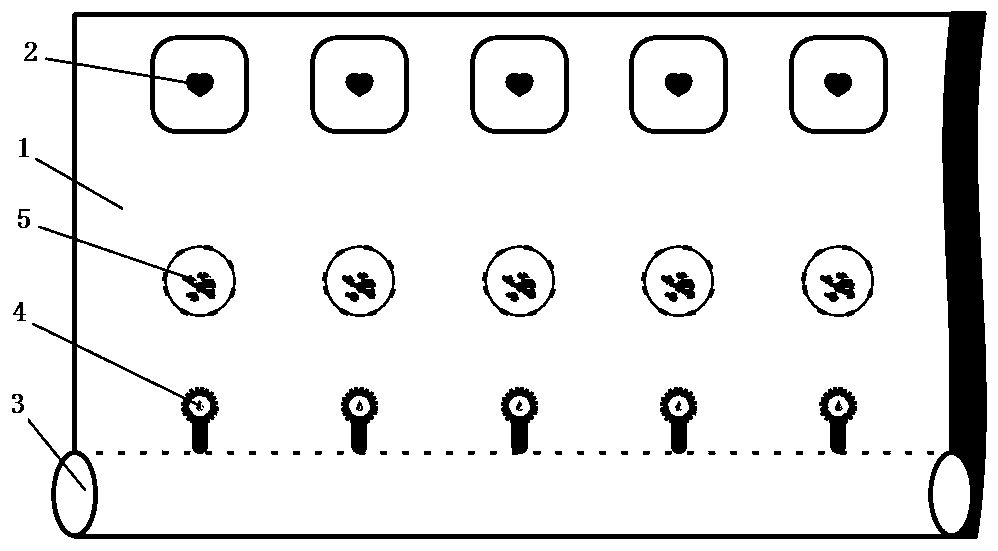

[0020] Example: such as figure 1 As shown, on the strip base belt with drip irrigation tape, the crop seeds are fixed along the base belt. The drip irrigation belt and the dripper are installed on the base belt, and the drip irrigation belt on the base belt is a tubular structure.

[0021] A reasonable layout is the drip irrigation belt, drippers and seeds on the transverse surface of the base belt. If there is a fertilizer bag, it is best to set the fertilizer bag between the seeds and the drip irrigation belt.

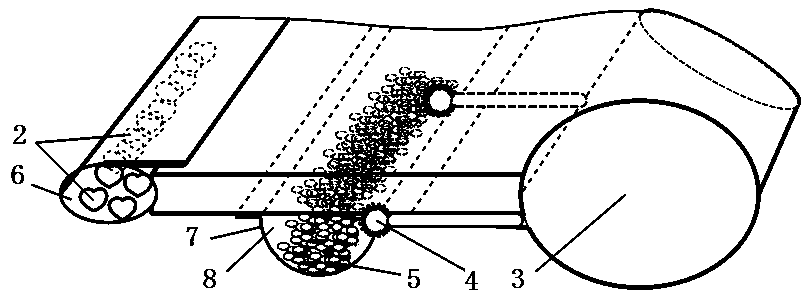

[0022] like figure 2 As shown, the seeds of drill crops are distributed in strips on the base belt, the base belt and the drip irrigation belt are parallel to the seed strips, and the distance between the dripper and the seed strips should be less than 10 cm.

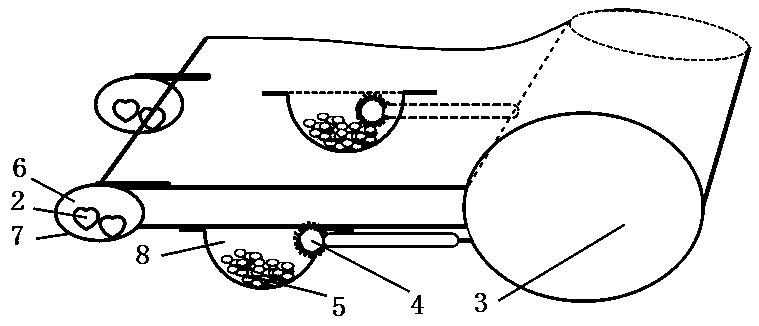

[0023] like image 3 As shown, the fixed seeds of hole-sowing crops are distributed in holes according to the requirement of plant spacing. The best way is to set 1 to 4 drippers around each hole. The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com