Online self-adaptive cut tobacco width measuring method based on machine vision

A machine vision and width measurement technology, applied in the computer field, can solve the problem of low efficiency of tobacco width measurement, achieve the effect of online and automation, improve accuracy, and ensure reference value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

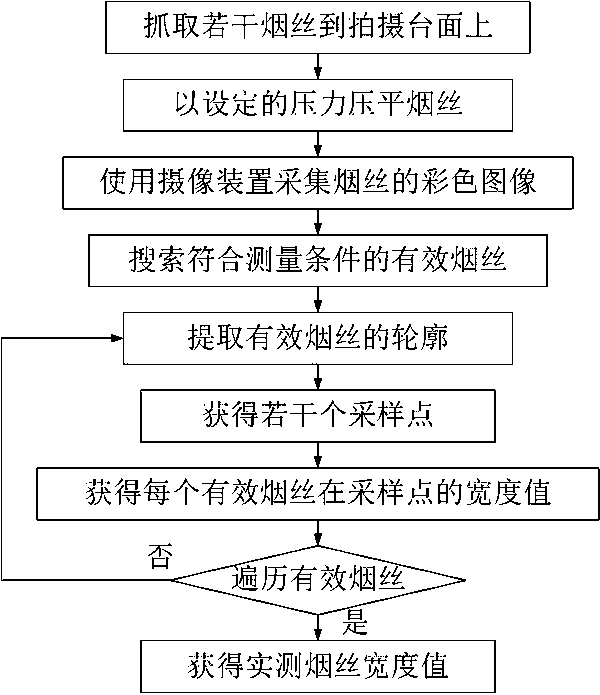

[0023] An online adaptive tobacco width measurement method based on machine vision, such as figure 1 As shown, this embodiment includes the following steps: A) Grab some shredded tobacco onto the shooting table, and flatten the shredded tobacco with a set pressure. Such as Figure 4 As shown, it is a real photo of shredded tobacco after flattening. The shredded tobacco is arranged randomly and overlapped. It is necessary to search for effective shredded tobacco that can be measured.

[0024] B) A camera is used to capture a color image of the shredded tobacco. An image enhancement operation is performed on the color image of the shredded tobacco, and the image enhancement operation includes increasing one or more of contrast, white balance or brightness balance. Carrying out image enhancement operation is helpful to improve the accuracy of tobacco width measurement result.

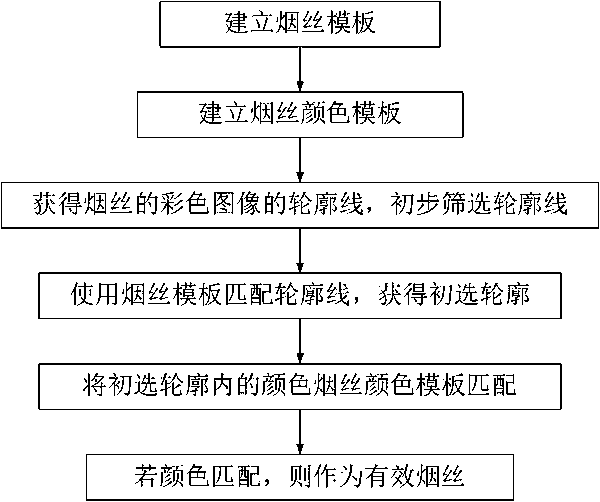

[0025] C) Use the preset shredded tobacco template to automatically search for effective shredded to...

Embodiment 2

[0038] An online self-adaptive shredded tobacco width measurement method based on machine vision. In this embodiment, a further improvement is made on the basis of Embodiment 1. In this embodiment, before performing step C), the following method is performed: estimating the proportion of effective shredded tobacco Whether it is up to the standard; the method for estimating whether the proportion of effective shredded tobacco is up to the standard includes: obtaining a decolorized copy of the color image of shredded tobacco, setting the color that falls within the preset color range of shredded tobacco to white, and setting the rest of the colors to black to obtain a decolorized copy; The average area S of the white area of , if the average area S is within the interval [Smin,Smax], Smin is the preset lower threshold, and Smax is the preset upper threshold, it is determined that the proportion of effective shredded tobacco reaches the standard; otherwise, it is determined that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com