Thin-wall square box rib-free and accurate positioning hollow floor construction method

A technology of precise positioning and hollow floor, which is applied in the direction of floor slabs, formwork/formwork/work frames, building components, etc. It can solve the problems of displacement of thin-walled square boxes, and achieve the effect of ensuring construction quality, high construction efficiency, and balanced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

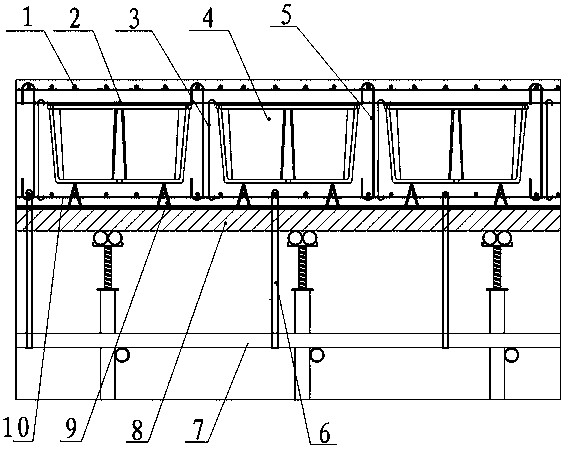

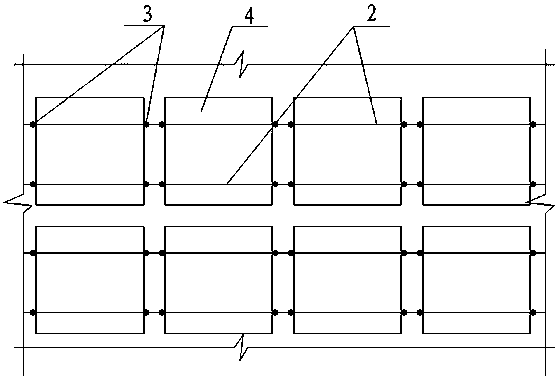

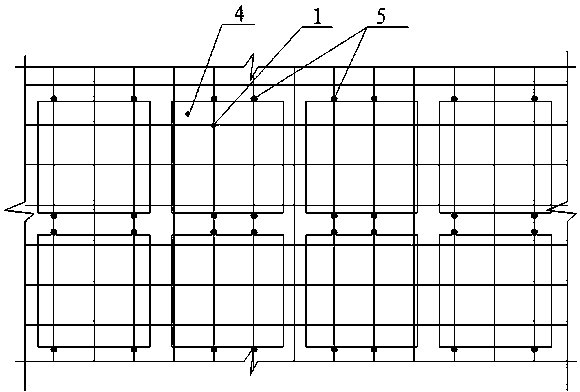

[0014] Such as figure 1 As shown, a thin-walled square box without ribs accurately locates the hollow floor construction method. Firstly, the formwork support 7 is built, and the floor formwork 8 is fixed on the formwork support 7. A total station and a level are used to support the floor formwork Accurately measure and place the positioning points and lines of the thin-walled square box; then start to bind the steel bars 10 at the lower part of the slab. 800-1200mm. The anti-floating iron wire 6 will pass through the floor formwork to bind the steel bar at the bottom of the plate and the formwork support 7 firmly;

[0015] Place the core mold positioning horse stool 9 above the floor template 8, and the positioning horse stool 9 is made of φ4mm cold-drawn steel wire, and the specific size is determined according to the actual project. After the positioning horse stool 9 is placed, the steel bar 10 at the bottom of the positioning horse stool 9 and the floor formwork is boun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com