Refuse dump platform structure and refuse dump platform greening method

A platform structure and dump site technology, applied in drainage structures, infrastructure engineering, botanical equipment and methods, etc., can solve the problems of difficult rooting and germination of plants, inconvenient construction, and difficulty in sanding, etc., so as to facilitate the rooting and growth of plants , increase the amount of rainwater infiltration, and the effect of easy rooting of plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

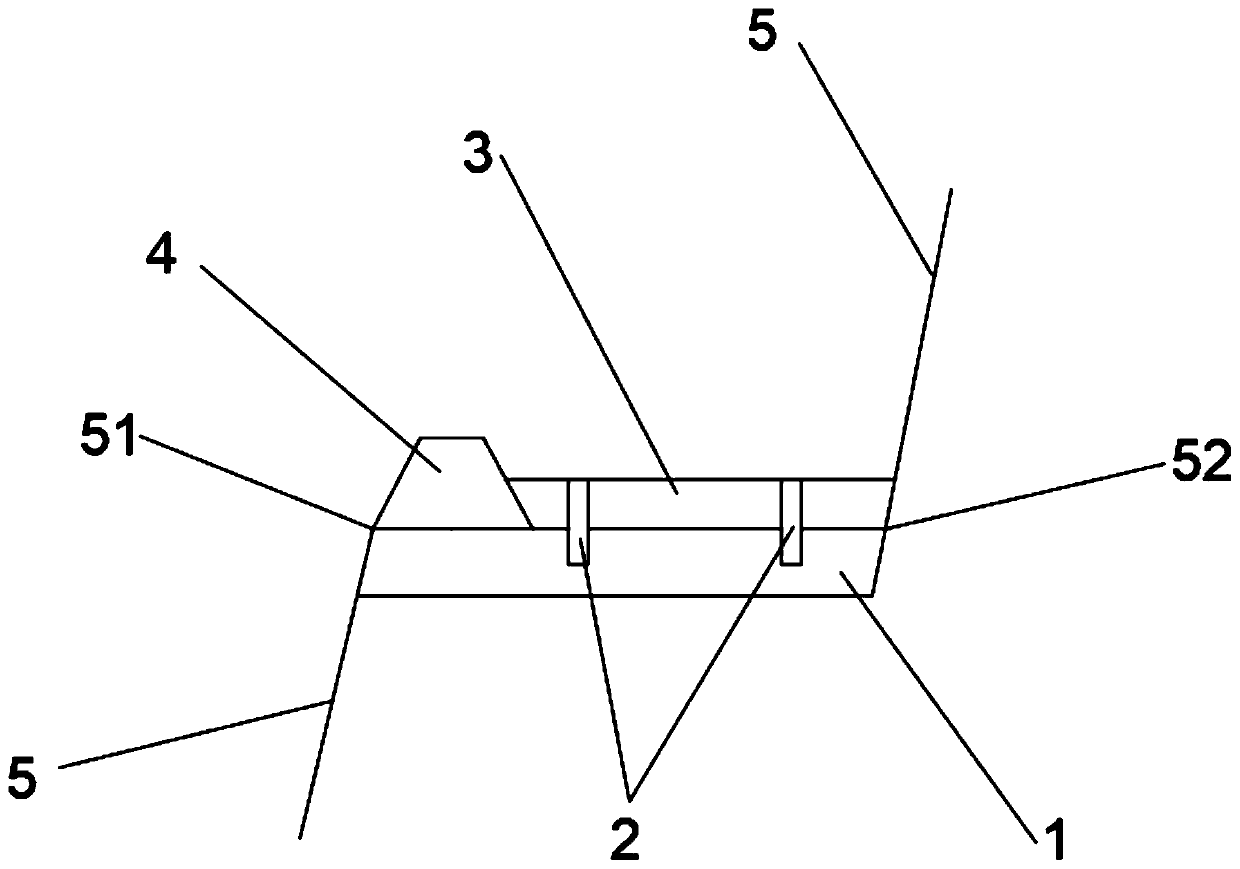

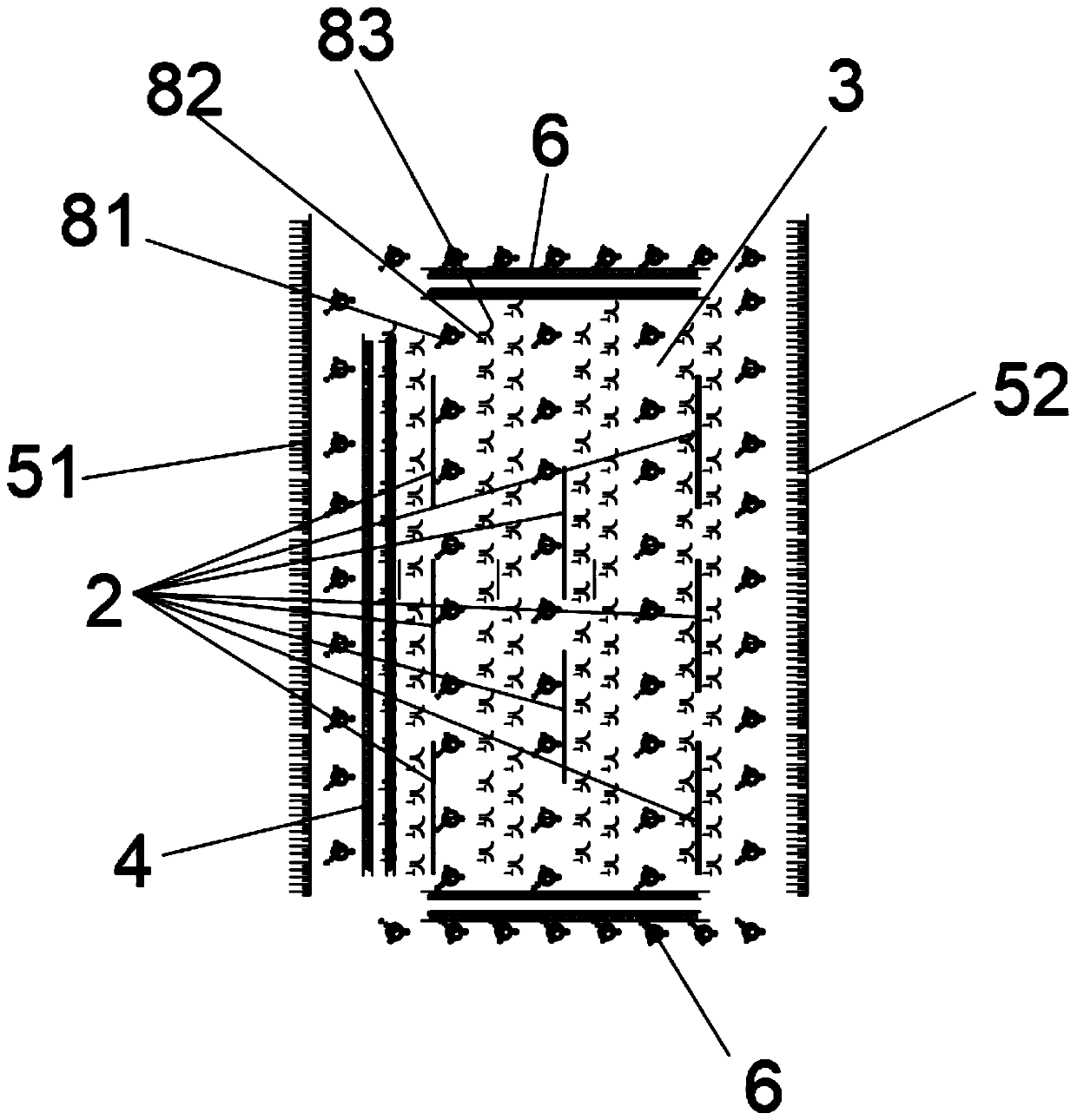

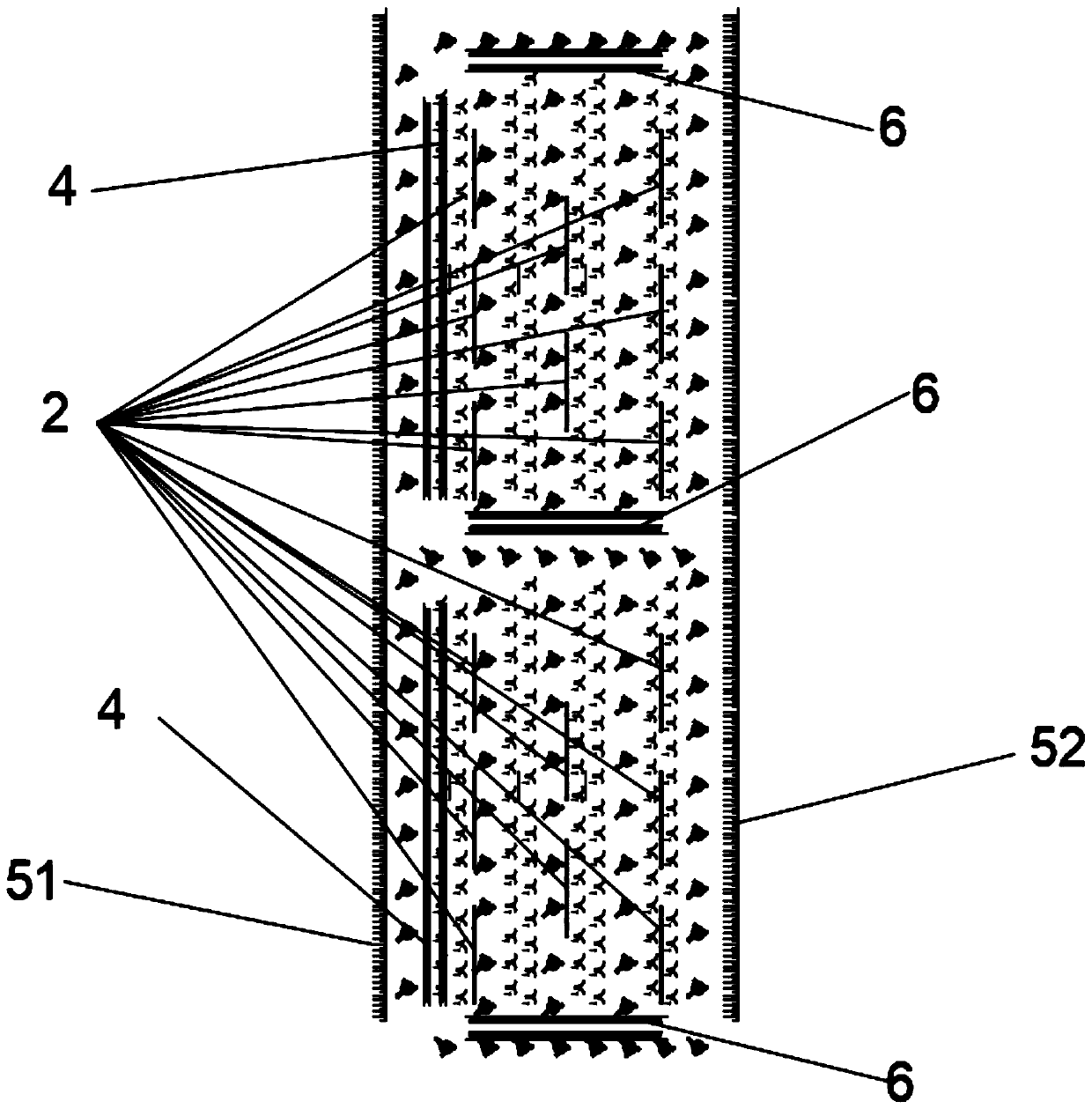

[0033] Such as Figure 1-Figure 4 As shown, the embodiment of the dump site platform structure disclosed by the present invention includes a platform layer 1, a soil layer 3 and a blocking plate 2, and the blocking plate 2 is made of a biological material, such as a wooden board, or by Salix salix, caragana, A compressed board made of biological materials such as sunflower stalks or leaves. The blocking board 2 is 50cm long, 20cm wide, and 1cm thick. The platform layer 1 is compacted. The surface of the platform layer 1 has grooves. The groove is 50cm long, 10cm wide, and 10cm deep. The lower part of the blocking plate 2 is plugged into the groove. The blocking plate 2 is perpendicular to the platform layer 1. The part of the blocking plate 2 buried in the groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com