Pattern sewing machine

A technology of pattern machine and frame, which is applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine control device, etc., can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

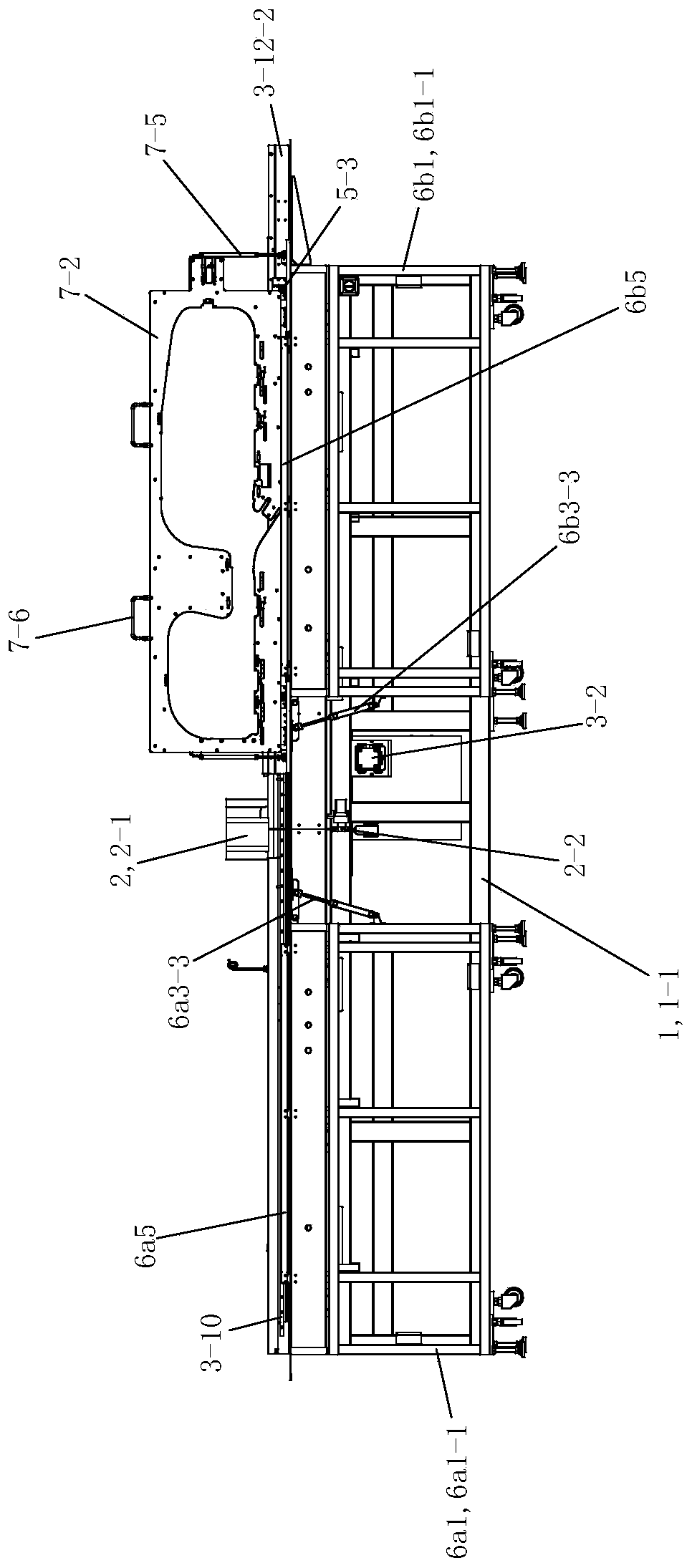

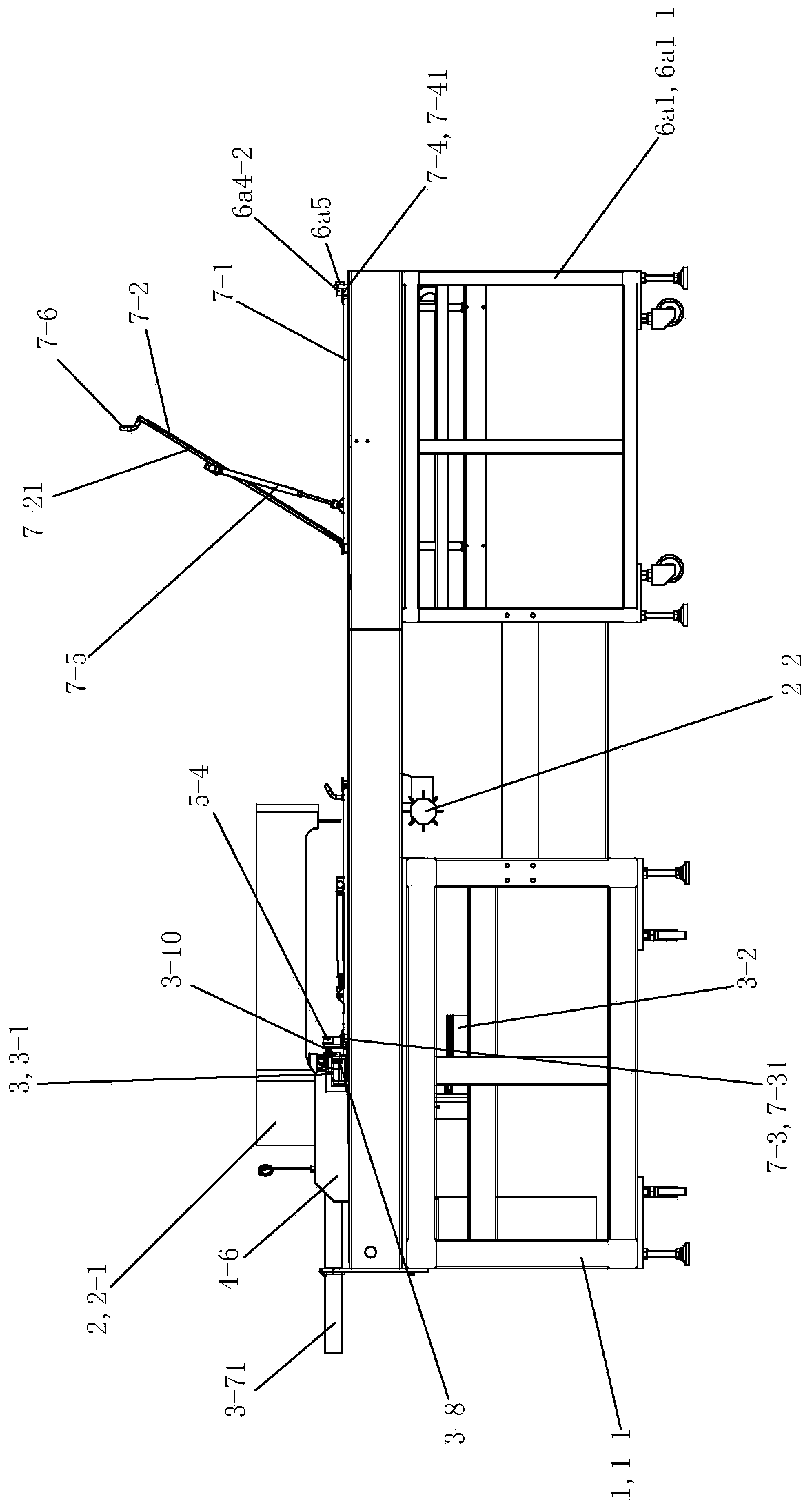

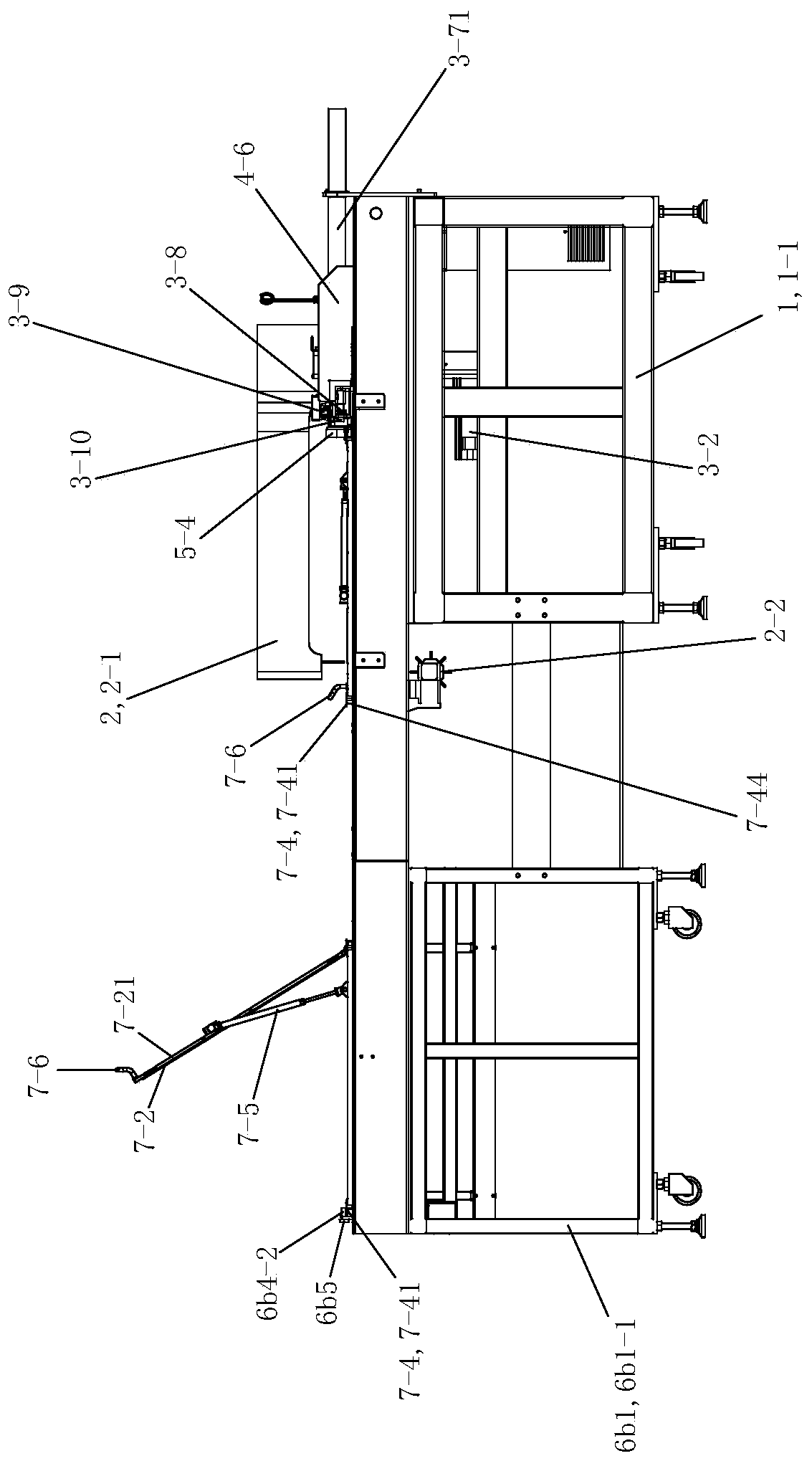

[0075] See Figure 1 to Figure 23 , The pattern machine of the present invention includes a table mechanism 1, a sewing mechanism 2, an X-direction drive mechanism 3, a Y-direction drive mechanism 4, a template quick assembly assembly 5, a mold changing device 6 and a template assembly 7.

[0076] See Figure 1 to Figure 11 , The workbench mechanism 1 includes a main frame 1-1, a workbench 1-2 and a moving platen assembly 1-3. The workbench 1-2 is fixedly arranged on the main frame 1-1. A movable platen hole is provided on the worktable 1-2. Four installation grooves 1-21 that run through the top and bottom of the workbench 1-2 are successively arranged on the workbench 1-2 from left to right.

[0077] See Figure 1 to Figure 11 , The mobile platen assembly 1-3 includes a movable platen 1-31, a platen lifting drive device 1-32, a platen front and rear drive device 1-33 and a platen guide assembly 1-34. The platen lifting drive device 1-32 includes a left platen lifting cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com