Industrial robot high-precision constant-force grinding method based on curved surface self-adaption

An industrial robot, high-precision technology, used in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as the inability to achieve high-precision constant force control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

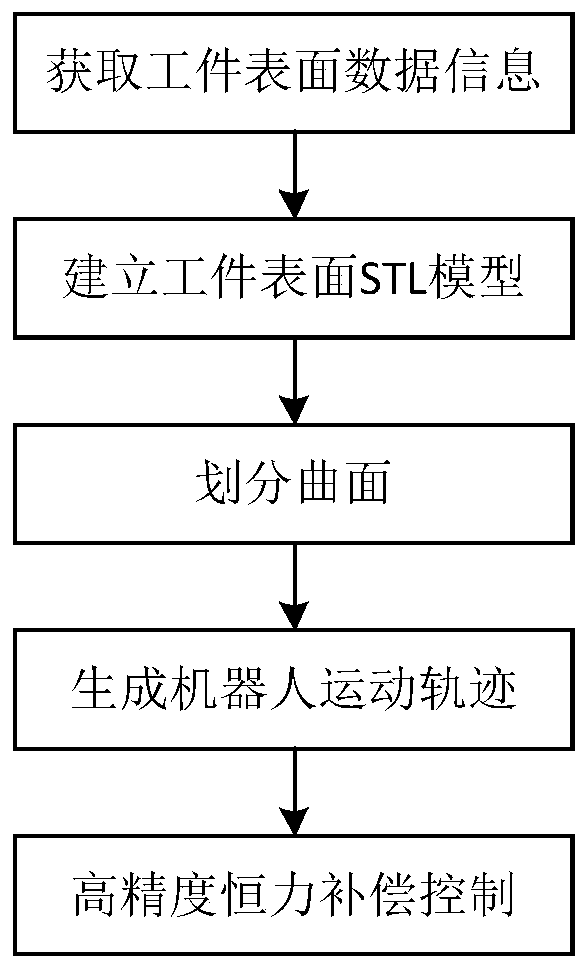

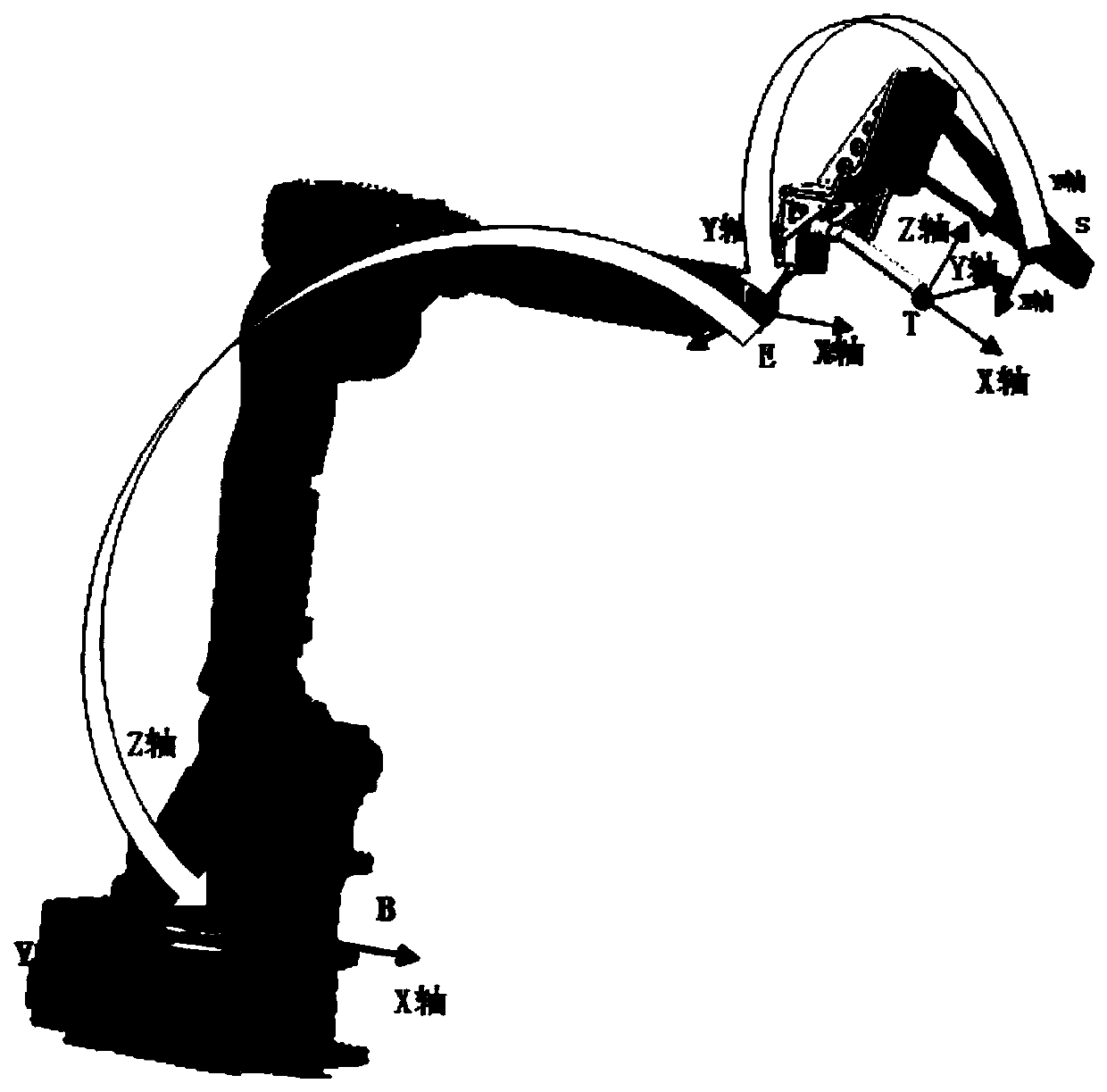

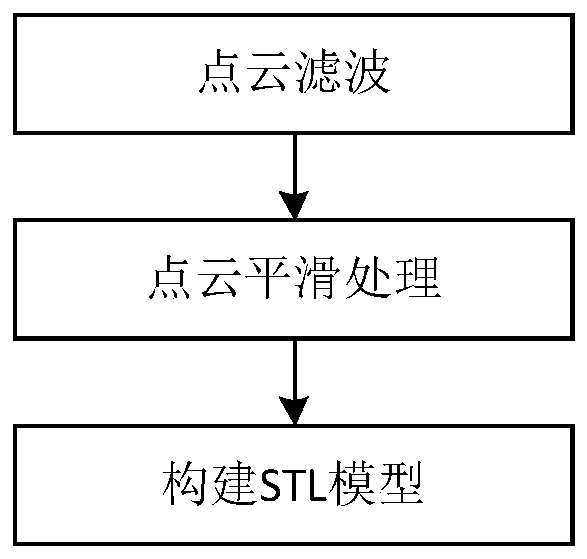

[0065] A high-precision constant force grinding method for an industrial robot based on surface self-adaption of the present invention, firstly uses a line structured light sensor to scan the surface of the workpiece to be polished to obtain a point cloud model of the workpiece surface, and then preprocesses the point cloud to establish the surface of the workpiece STL (stereolithography) model, and then construct the feature frame according to the STL model of the workpiece surface, use the cutting plane projection method to generate the robot grinding trajectory, and finally realize the constant grinding process by using the force control algorithm based on the real-time feedback of the six-dimensional force / torque sensor force control. Such as figure 1 As shown, the method includes the following steps:

[0066] 1. Obtain the surface data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com