Flying bar fixing seat and cavity filter

A fixed seat and flying rod technology, applied in the field of communication, can solve problems such as poor index, difficult installation, failure, etc., to prevent the processing tolerance from being too small, reduce shaking, and ensure stable combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in combination with the embodiments and accompanying drawings.

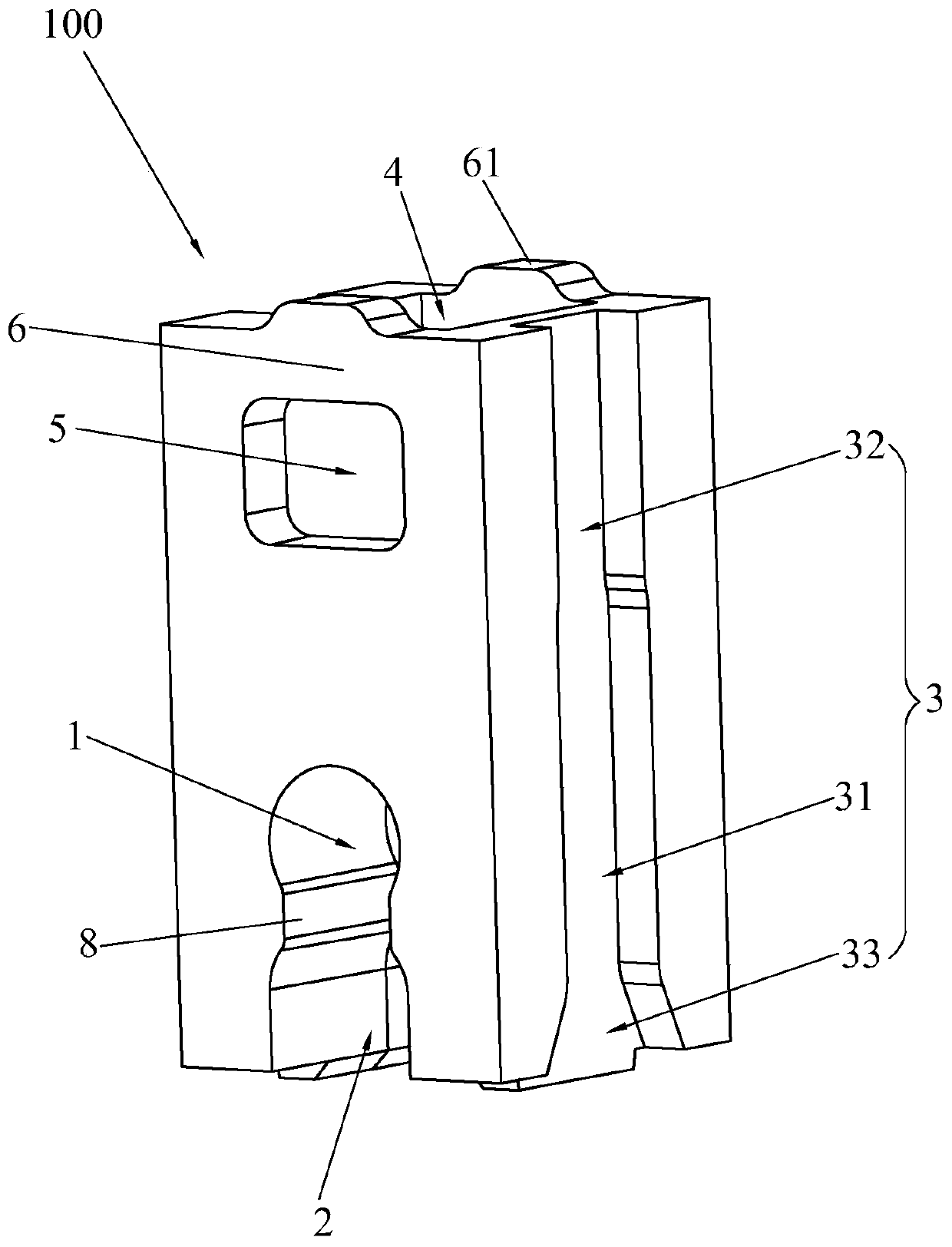

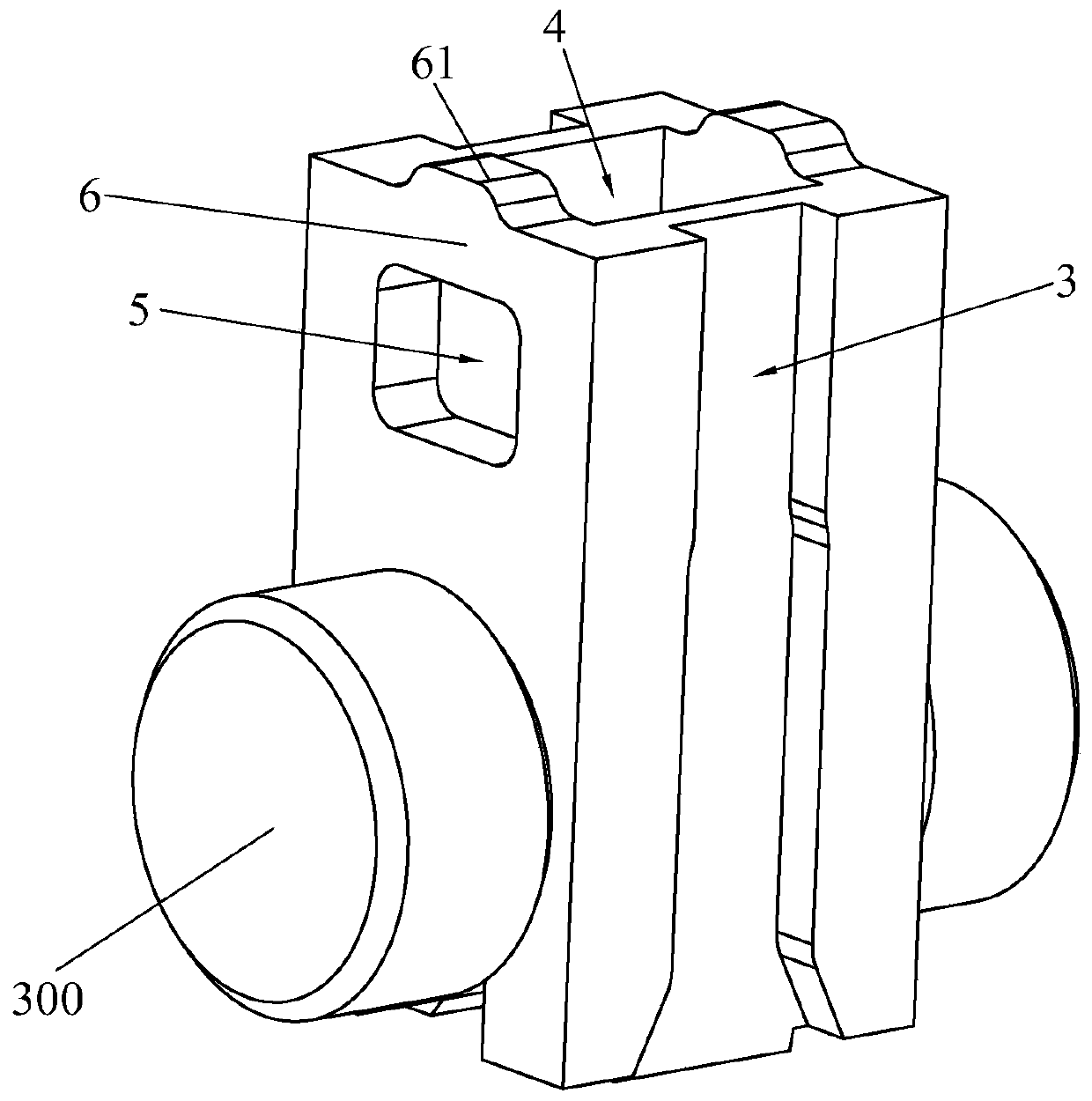

[0022] see Figure 1 to Figure 4 , the present invention discloses a flying rod holder 100. The flying rod holder 100 is in the shape of a cuboid as a whole. The lower part of the flying rod holder 100 is formed with a flying rod positioning hole 1 and a lower end opening 2 that penetrate front and rear. The upper end of the lower opening 2 It communicates with the fly rod positioning hole 1, the lower end of the lower opening 2 penetrates downward, the left and right sides of the fly rod holder 100 are respectively provided with vertically penetrating installation slots 3, and the upper part of the fly rod holder 100 is provided with a vertically extending And the groove 4 that penetrates upwards, the cross section of the groove 4 is rectangular, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com