Intelligent asphalt pavement repairing vehicle and construction method

A technology for asphalt pavement and car body, applied in satellite radio beacon positioning system, measuring device, instrument, etc., can solve problems such as easy sticking of knives, stop cleaning, and affect milling efficiency, so as to improve construction efficiency and safety, Reduce the difficulty of equipment control and improve the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

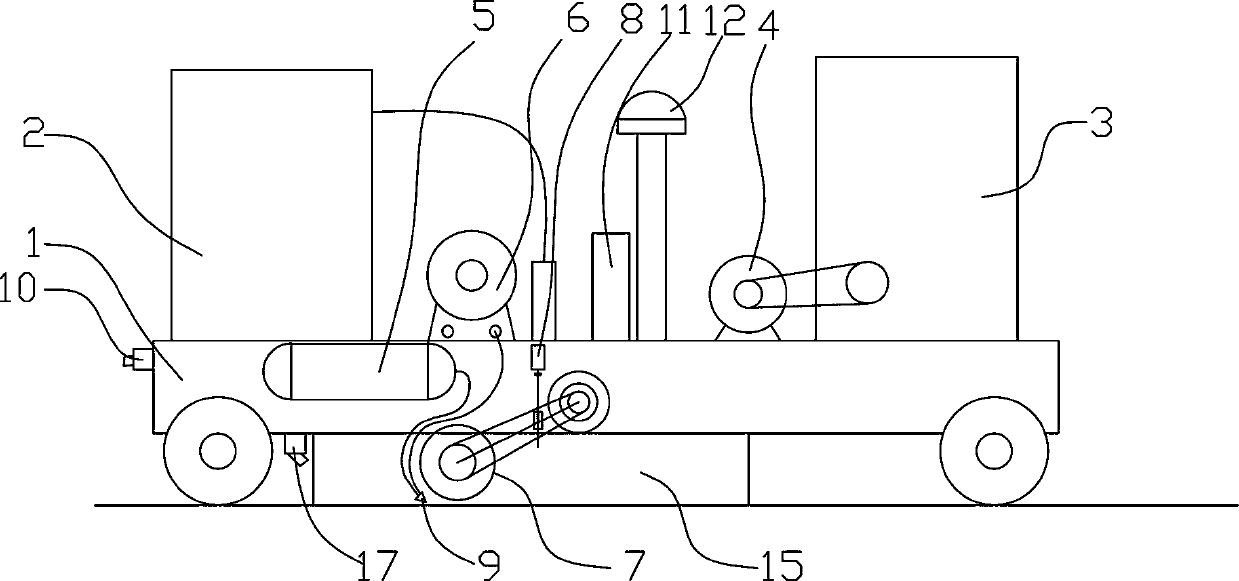

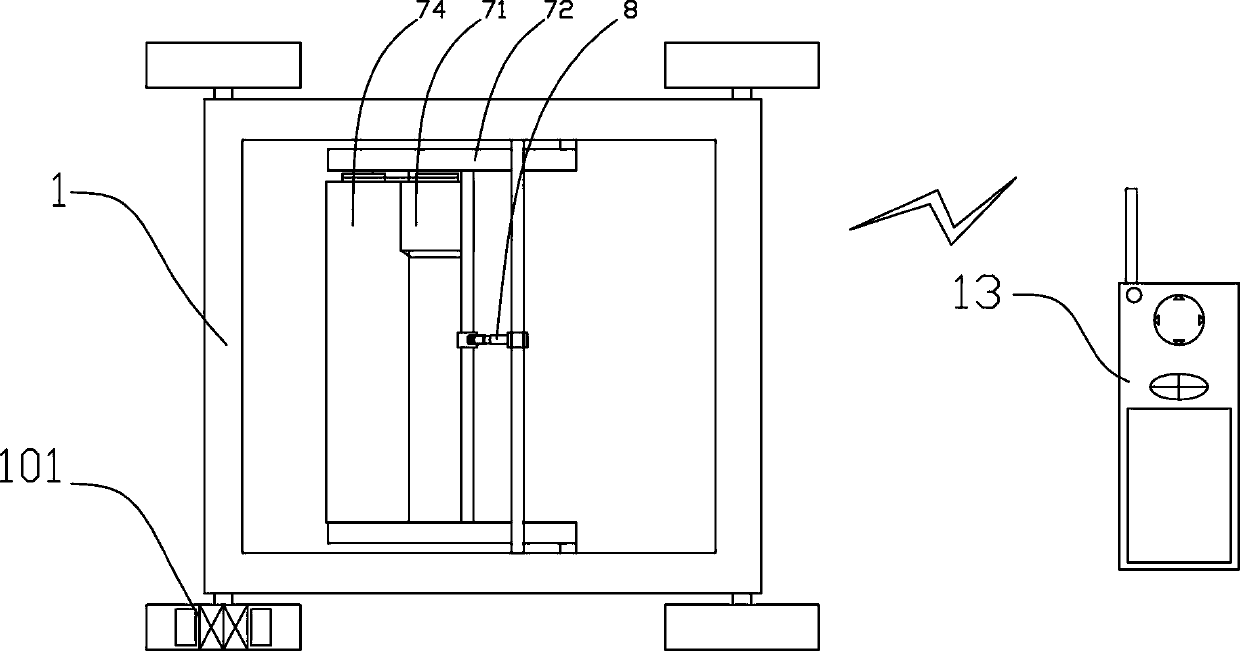

[0054]An intelligent asphalt pavement repairing vehicle comprises a traveling vehicle body 1. The traveling vehicle body 1 in this example is a traveling device driven by a motor, and a power unit 3 is provided on the traveling vehicle body 1. The power unit 3 preferably adopts a diesel engine. The power device 3 is connected with the generator 4 through the transmission mechanism, and the generator 4 is connected with the storage battery. The electric energy of storage battery is used for driving traveling device to walk. Or drive other mechanisms to run, such as fans and planing and milling devices.

[0055] A liftable planer and milling device 7 is provided on the traveling car body 1;

[0056] In front of the planing and milling device 7, a refrigerant nozzle 9 is provided, and the refrigerant nozzle 9 is connected with the refrigerant storage tank 5, and the refrigerant nozzle 9 is used to spray refrigerant to cool down the road surface of the road surface marking 14 to ...

Embodiment 2

[0081] Such as Figure 8 Among them, a kind of construction method that adopts above-mentioned intelligent asphalt pavement finishing vehicle, comprises the following steps:

[0082] S1, positioning the traveling car body 1 and the position to be repaired on the road surface, so that the planing and milling device 7 is aligned with the position to be repaired on the road surface;

[0083] S2. Start the walking vehicle body 1 to start walking, start the refrigerant nozzle 9 to spray and cool down the position where the road surface is to be repaired, and locally cool the position where the road surface is to be repaired to below 4°C;

[0084] S3, the planing and milling device 7 passes through the position to be repaired on the road surface, and clears the position to be repaired on the road surface, and the swing frame lifting device 8 controls the clearing height of the planing and milling device 7;

[0085] S4. Repair the construction site with asphalt concrete repair mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com