High-performance long-acting supercharger

A supercharger, high-performance technology, applied in the direction of machines/engines, pumping devices for elastic fluids, non-variable pumps, etc., can solve the problem of sintering failure of the lubrication system, complex structure of the part body, and manufacturing costs High cost and other problems, to achieve low space occupation, high-efficiency heat transfer, and reduce the effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

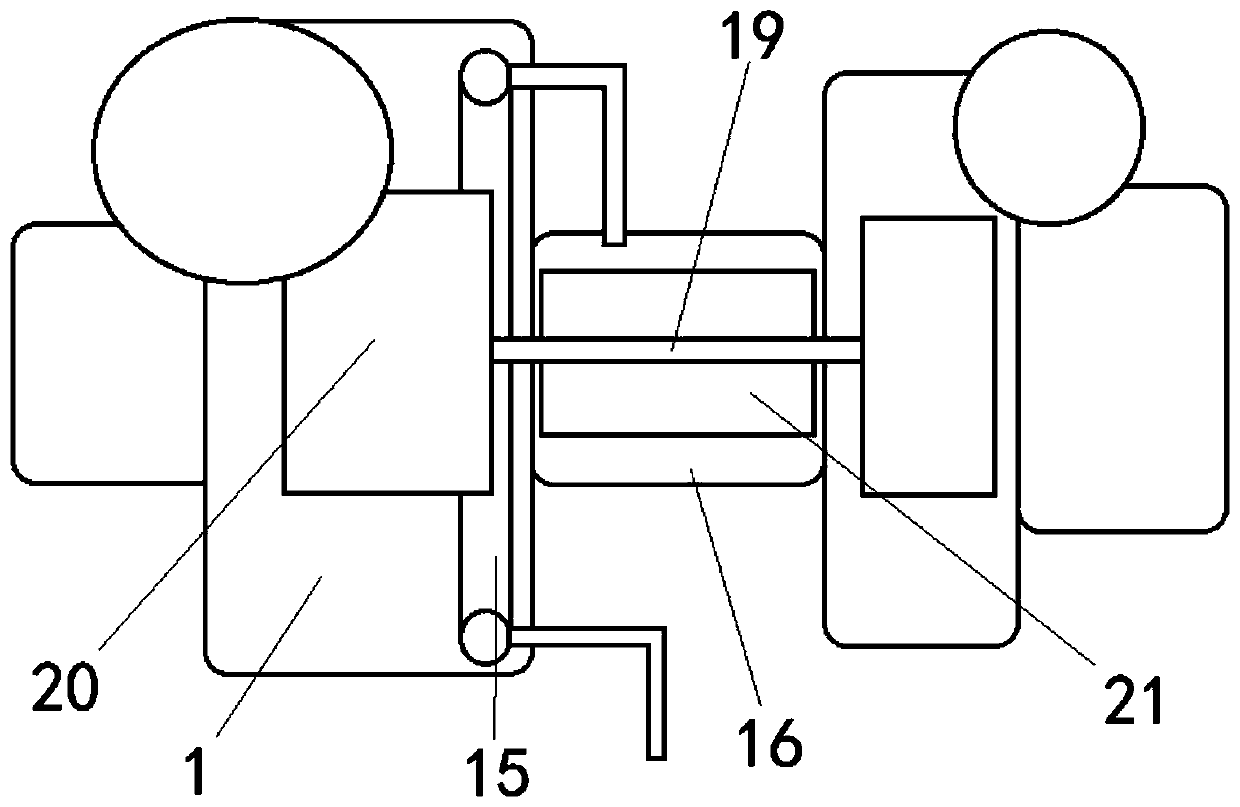

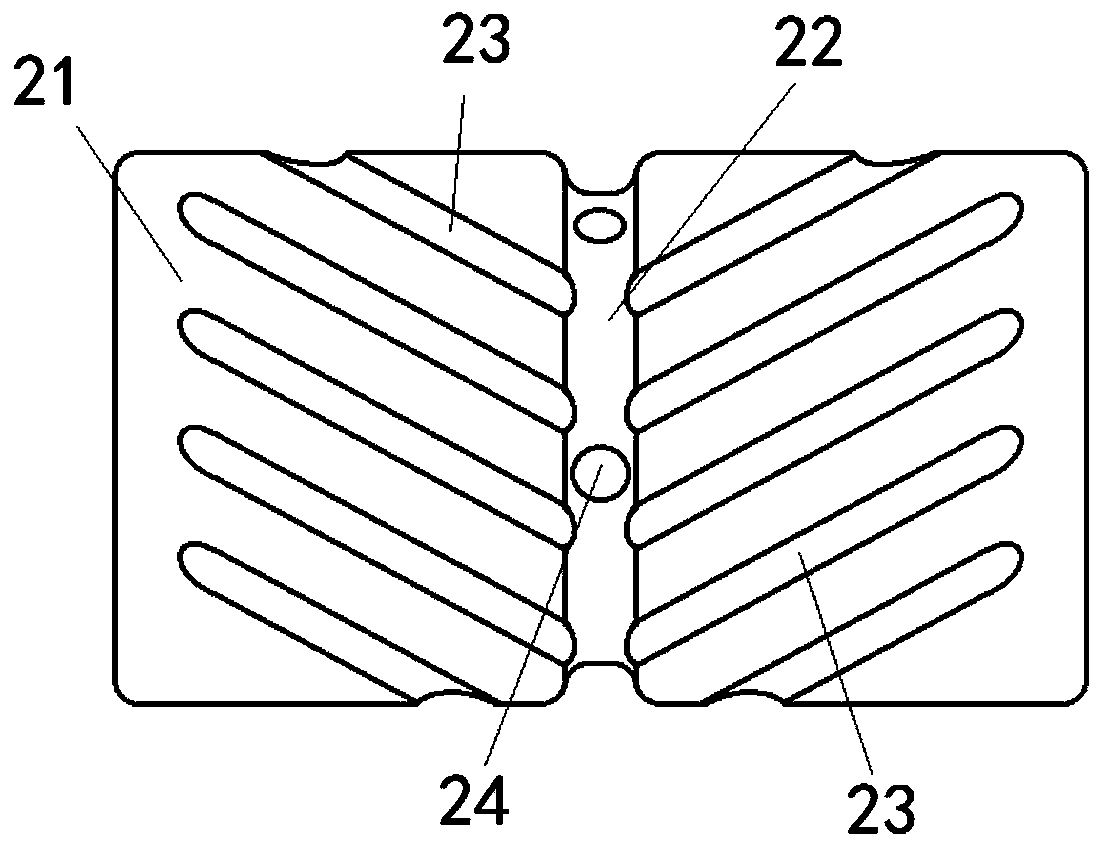

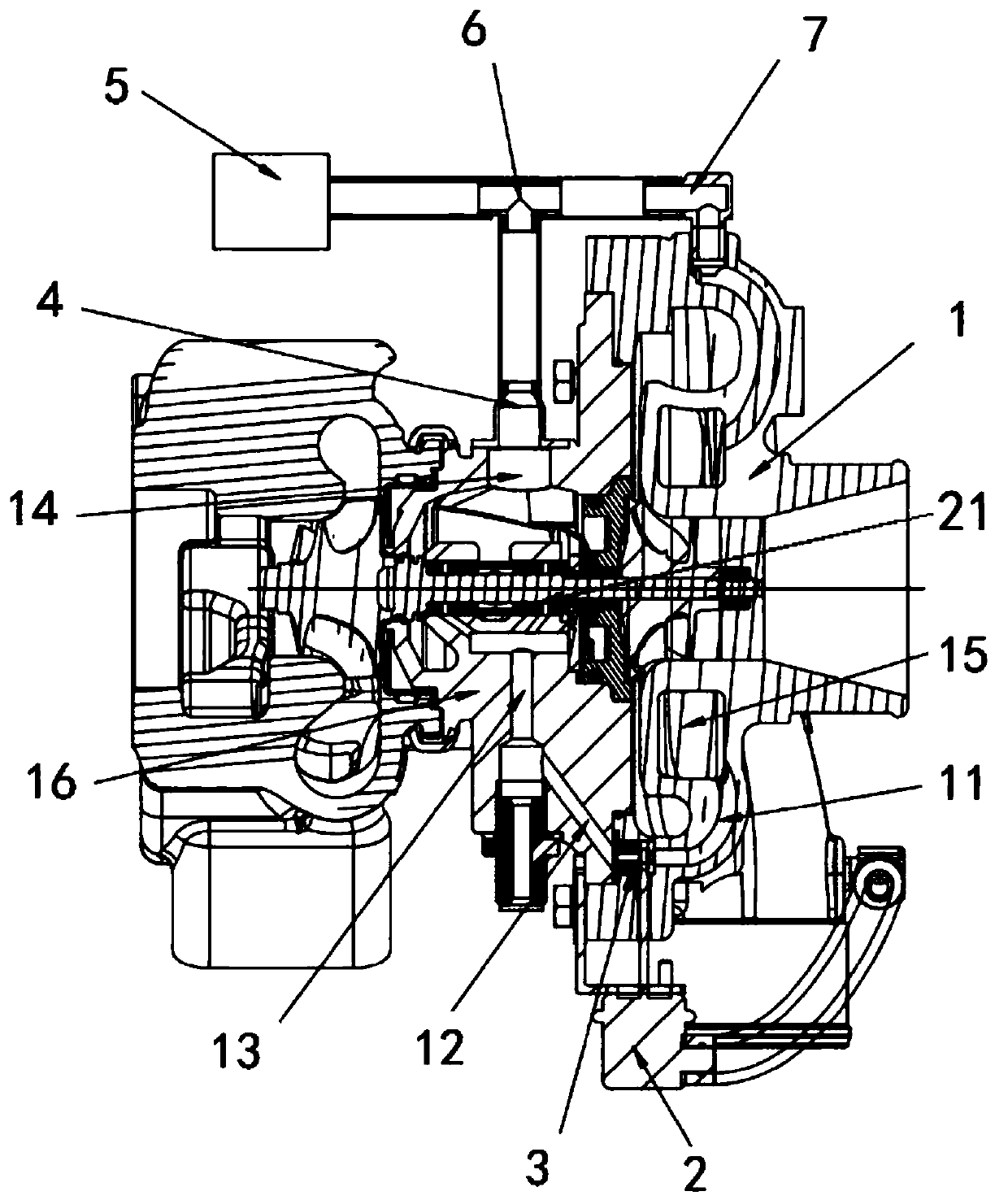

[0019] according to figure 1 , figure 2 , image 3 , Figure 4 , a high-performance long-term supercharger, consisting of a bearing seat 16 and a compressed air chamber 1 installed at one end of the bearing seat 16, the bearing seat 16 is provided with a rotating shaft 19 extending into the compressed air chamber 1, One end of the rotating shaft 19 in the compressed air cavity 1 is provided with an air compressor fan blade 20, wherein: the rotating shaft 19 cooperates with the bearing seat 16 through a thick film bearing 21, and in the thick film bearing 21 body, An annular oil groove 22 is set at the axial center of the outer wall, and the body of the thick film bearing 21 is divided into two symmetrical parts; The oil gathering groove 23 of the inner wall is the same as the working direction of rotation, and the oil gathering groove 23 of the outer wall is opposite to the working direction of rotation. The connecting end of the oil gathering groove 23 and the annular oil...

Embodiment 2

[0022] according to image 3 , Figure 4 , the main oil passage connected with the high-pressure oil passage of the bearing seat 16 is provided in the said compressed air chamber 1, and the said main oil passage is the fifth channel 15 which is set along with the described compressed air chamber 1; on the said main oil passage A first passage 11 and a secondary oil passage respectively connected to the high-pressure oil passage are also provided; the secondary oil passage and the high-pressure oil passage are jointly connected to the oil pan 5 through a communication component. The first passage 11 is installed with a control mechanism for controlling the oil flow rate according to the different output power of the compressor fan blade 20 ; The executive part includes a booster 2 installed on the compressed air chamber 1, the sensing end of the booster 2 is connected to the air outlet channel of the compressed air chamber 1, and the control end of the booster 2 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com