Jacking construction method for welding large-span spherical cylindrical reticulated shell

A technology of cylindrical reticulated shells and construction methods, which is applied in the direction of lifting devices, buildings, building structures, etc., can solve problems such as many uncontrollable factors, dangerous operations, and long hours of high-altitude operations, so as to achieve reliable safety risks and safety risk control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

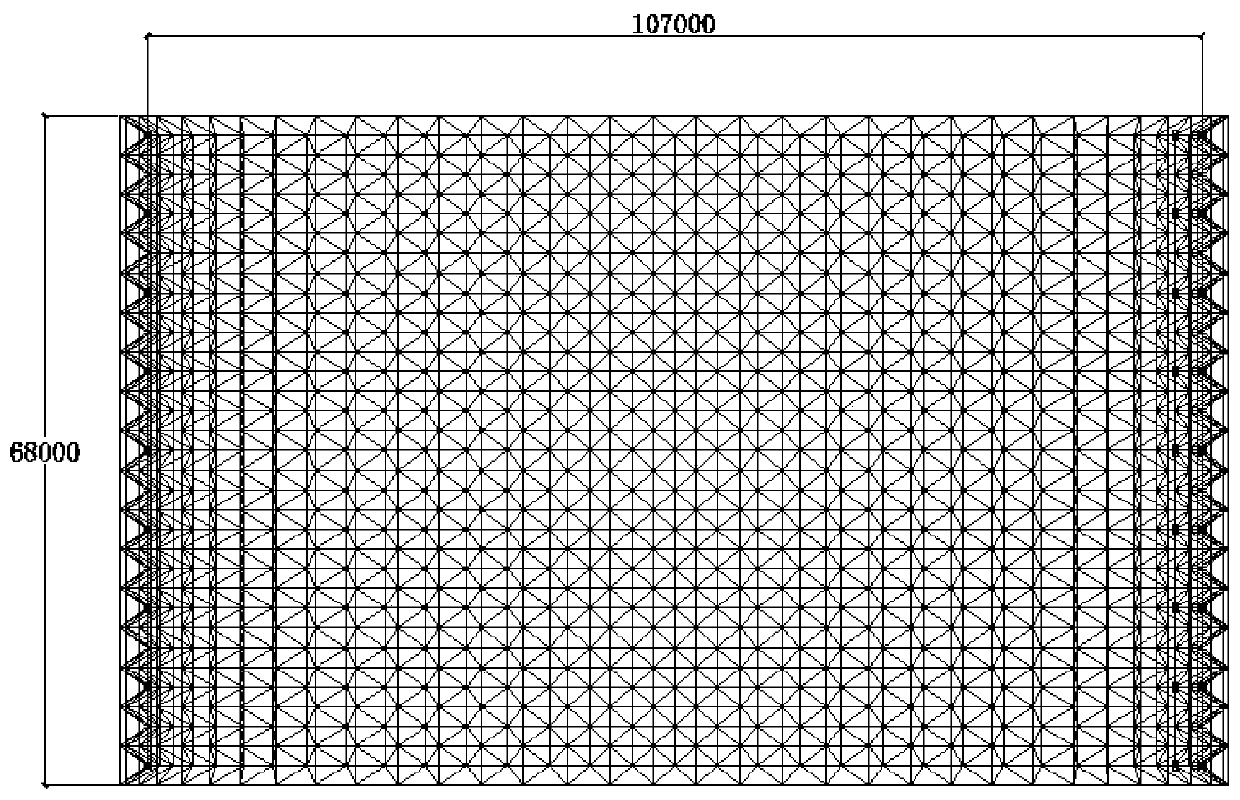

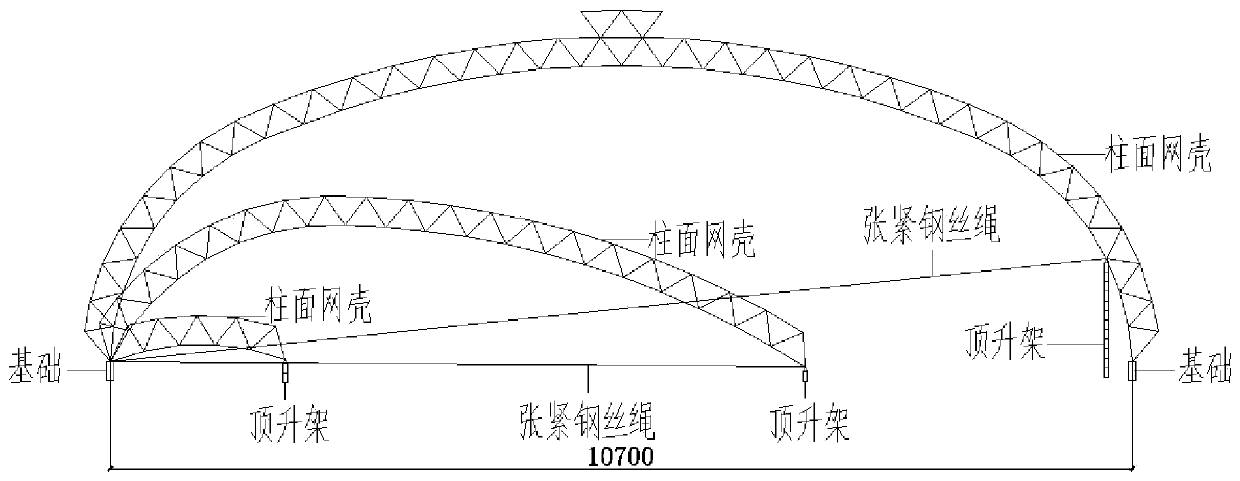

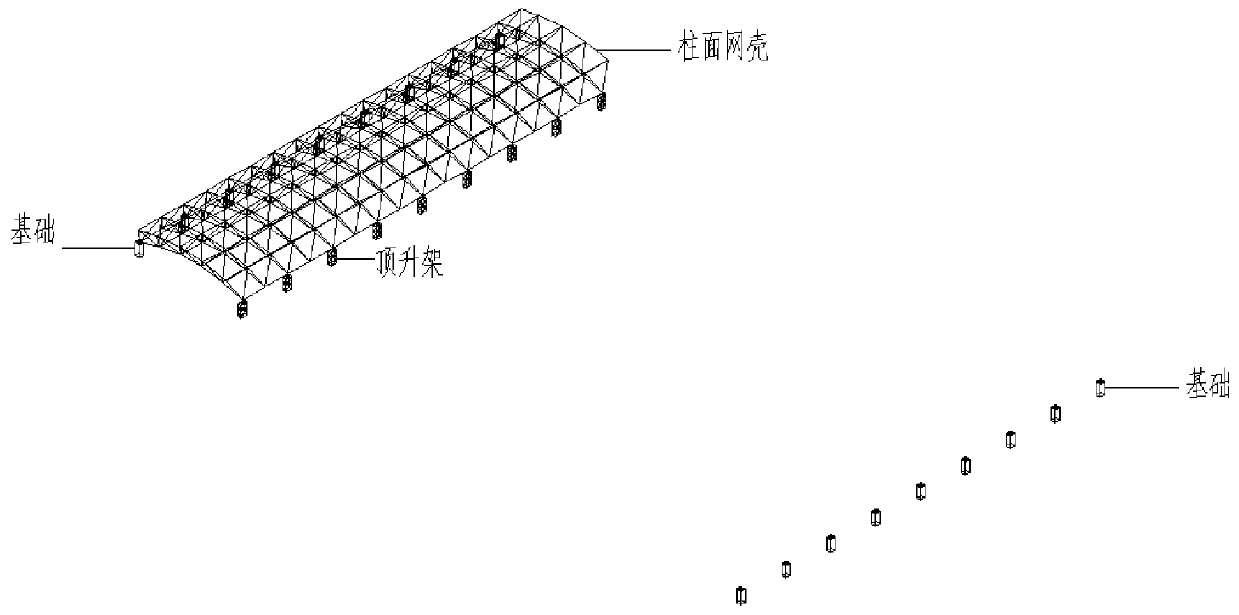

[0029] Such as Figure 1-8 shown.

[0030] A sort of figure 1 The specific steps of the jacking construction method for the large-span welded spherical reticulated shell shown are as follows:

[0031] 1. Basic review;

[0032] First, according to the design drawings, the chief supervisory engineer organizes the design and construction units to check the axis size, position, levelness, elevation and support anchor bolt position and other parameters of the foundation cross line popped up by the civil engineering unit, and review according to the requirements of the design and construction specifications , to rectify the parameters that do not meet the requirements of the design and construction specifications, and to review the rectified basis and then go through the intermediate handover procedures. The position, elevation, levelness of the top plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com