Force and electricity complementary detecting probe, and exceeded pouring detecting device and method

A detection probe and detection device technology, which is applied in the testing of infrastructure, construction, infrastructure engineering, etc., can solve problems such as difficulty in distinguishing concrete laitance and aggregate concrete, large fluctuation of fluid medium, measurement error, etc. The effect of test efficiency and test accuracy, fine control of overfill height, and widening of the detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

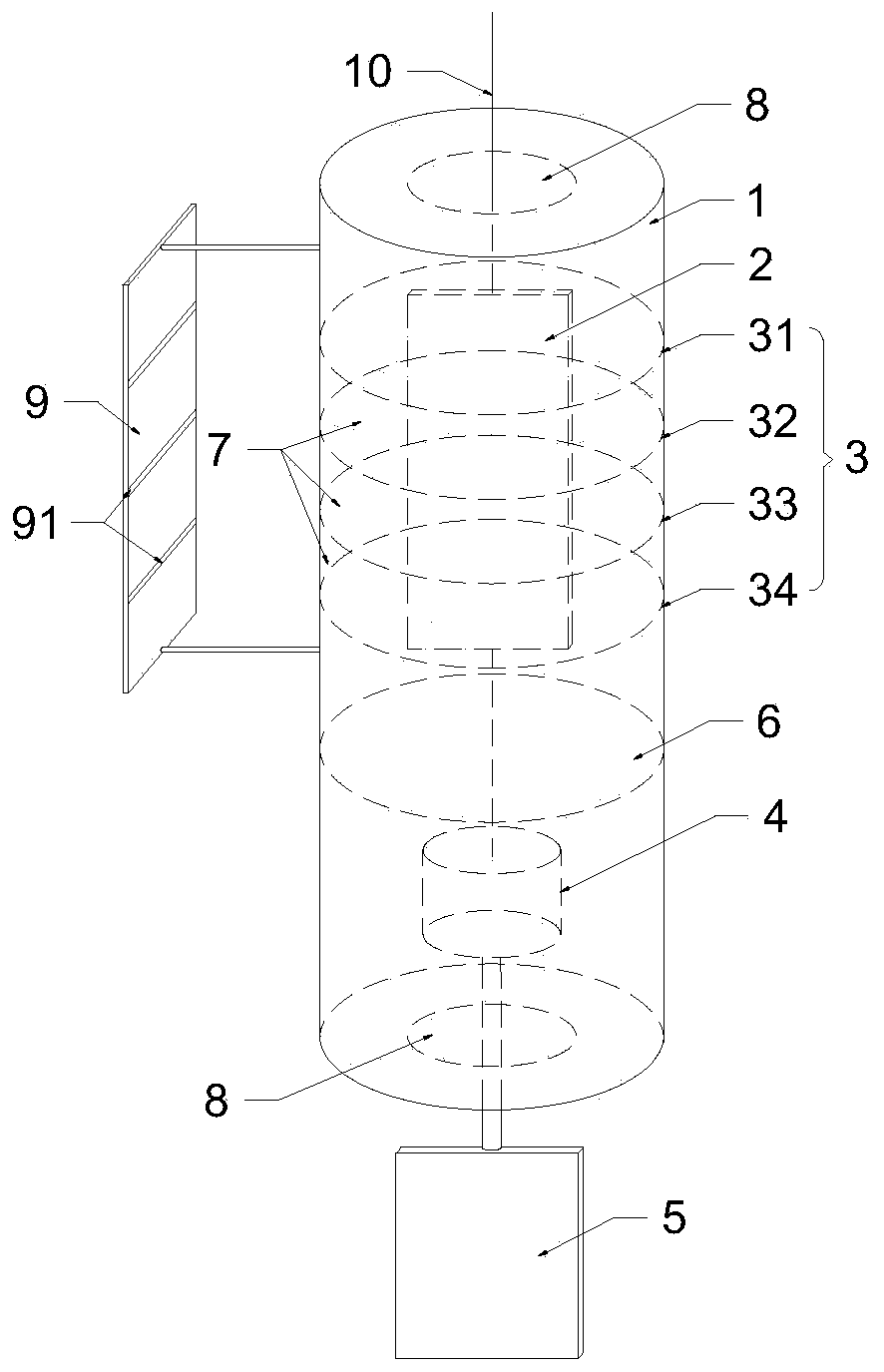

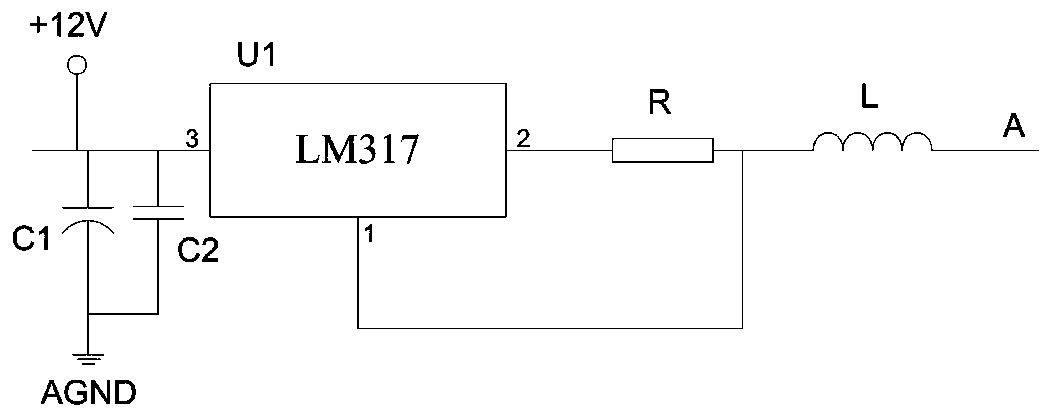

[0043] The electrode ring 3 includes a first electrode ring 31, a second electrode ring 32, a third electrode ring 33, and a fourth electrode ring 34 that are uniformly spaced in sequence along the axial direction of the housing 1. The material of the electrode ring 3 is preferably stainless steel, so An insulating filling material 7 is provided between the electrode rings 3 and between the electrode ring 3 and the housing 1; the electrical parameter measurement module provides a constant current field to the first electrode ring 31 and the fourth electrode ring 34, and The voltage between the second electrode ring 32 and the third electrode ring 33 is collected to obtain electrical parameter information of the concrete; the electrical parameter information may be one of electrical parameter information such as resistivity, capacitance, inductance or electrical polarization. As an implementation, the electrical parameter measurement module includes a power supply device, a volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com