Quantum dot ink, display panel manufacturing method and display panel

A technology for a display panel and a manufacturing method, which is applied to the manufacturing and application of inks, semiconductor/solid-state devices, etc., can solve the problems that the fluidity of quantum dot ink cannot be fundamentally suppressed, and the improvement effect is limited, so as to achieve excellent display quality and improve smoothness. uniformity and uniformity, the effect of inhibiting diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as [up], [down], [front], [rear], [left], [right], [inner], [outer], [side], etc., are only for reference Additional schema orientation. Therefore, the directional terms used are for describing and understanding the present invention, not for limiting the present invention. In the figures, structurally similar elements are denoted by the same reference numerals.

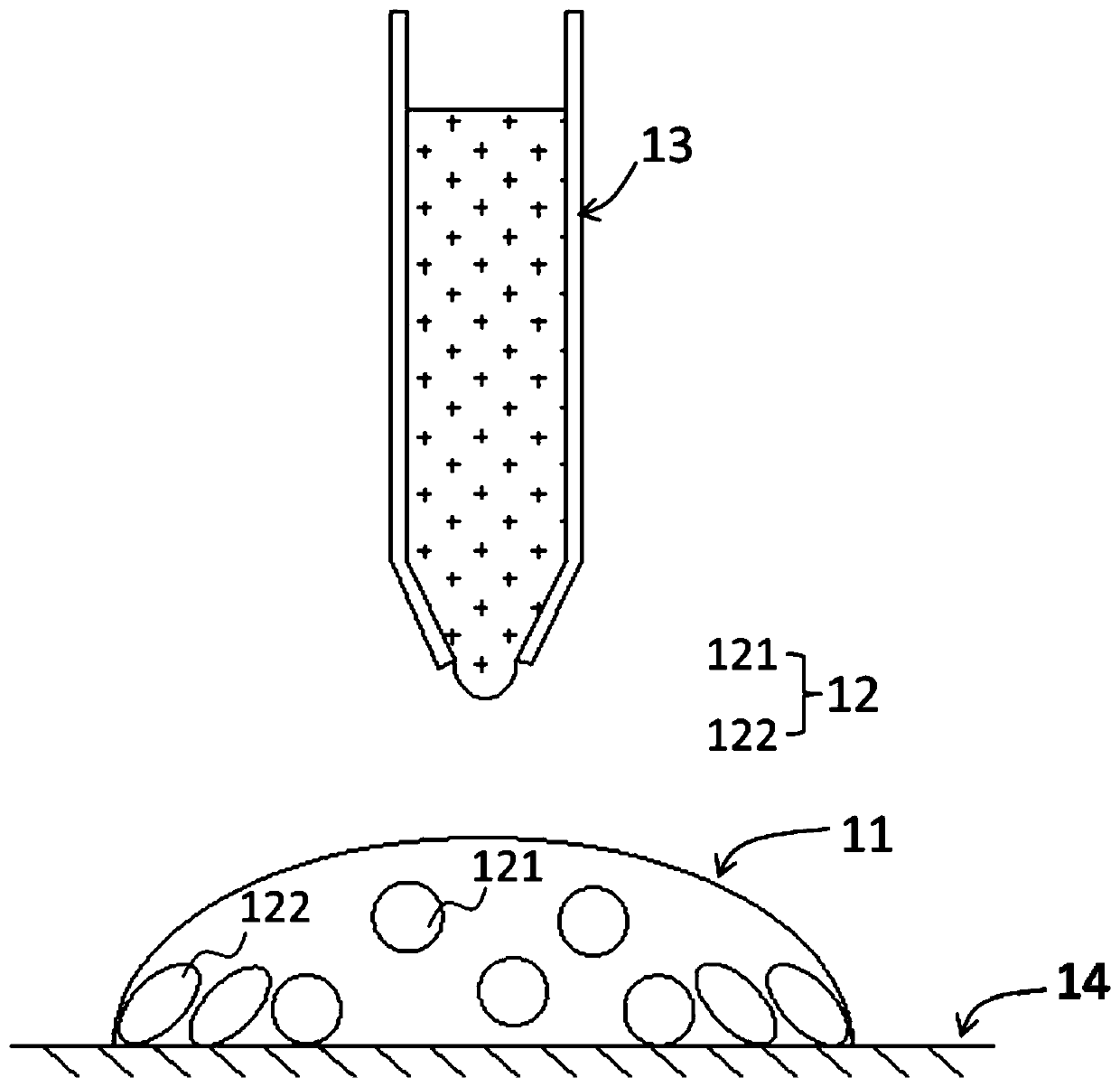

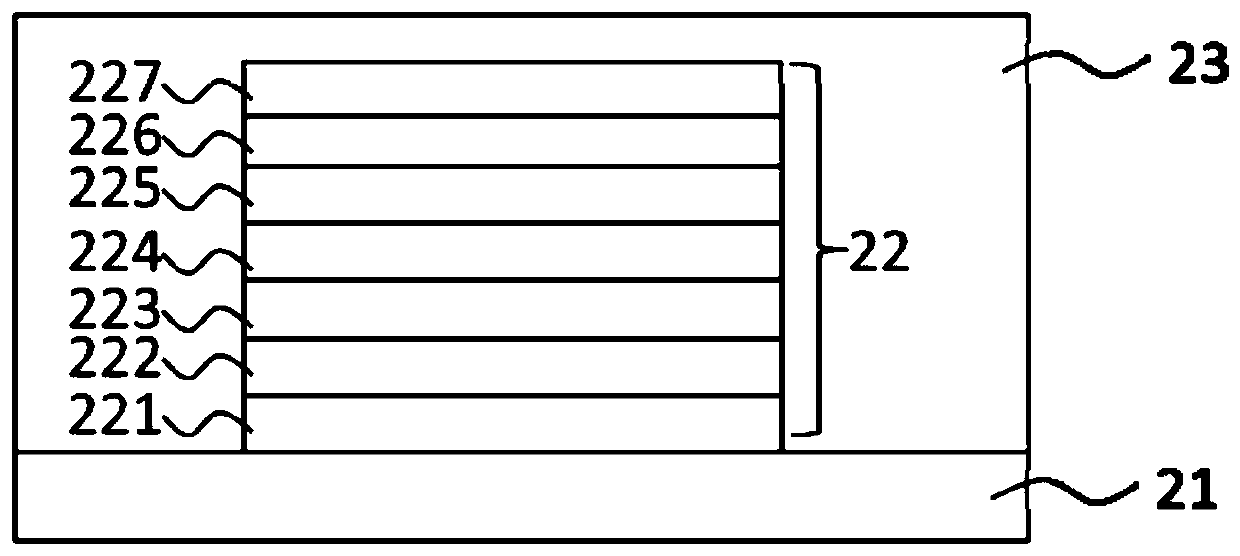

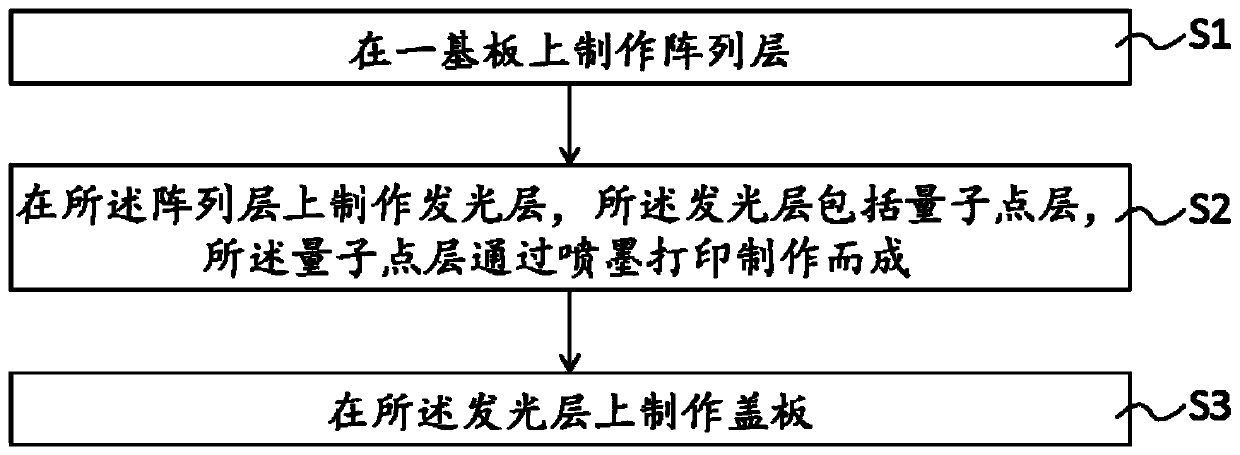

[0037] Embodiments of the present invention provide a quantum dot ink, a method for fabricating a display panel using the quantum dot ink, and a display panel fabricated using the quantum dot ink. By adding blocking quantum dots to the quantum dot ink, the diffusion of the quantum dot ink in the inkjet printing process is suppressed, thereby eliminating the coffee ring effect of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com