Automatic detection signature device for production line

An automatic detection and production line technology, applied in the direction of measuring devices, packaging automatic control, packaging, etc., can solve the problems of low degree of automation, high labor intensity, low detection efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

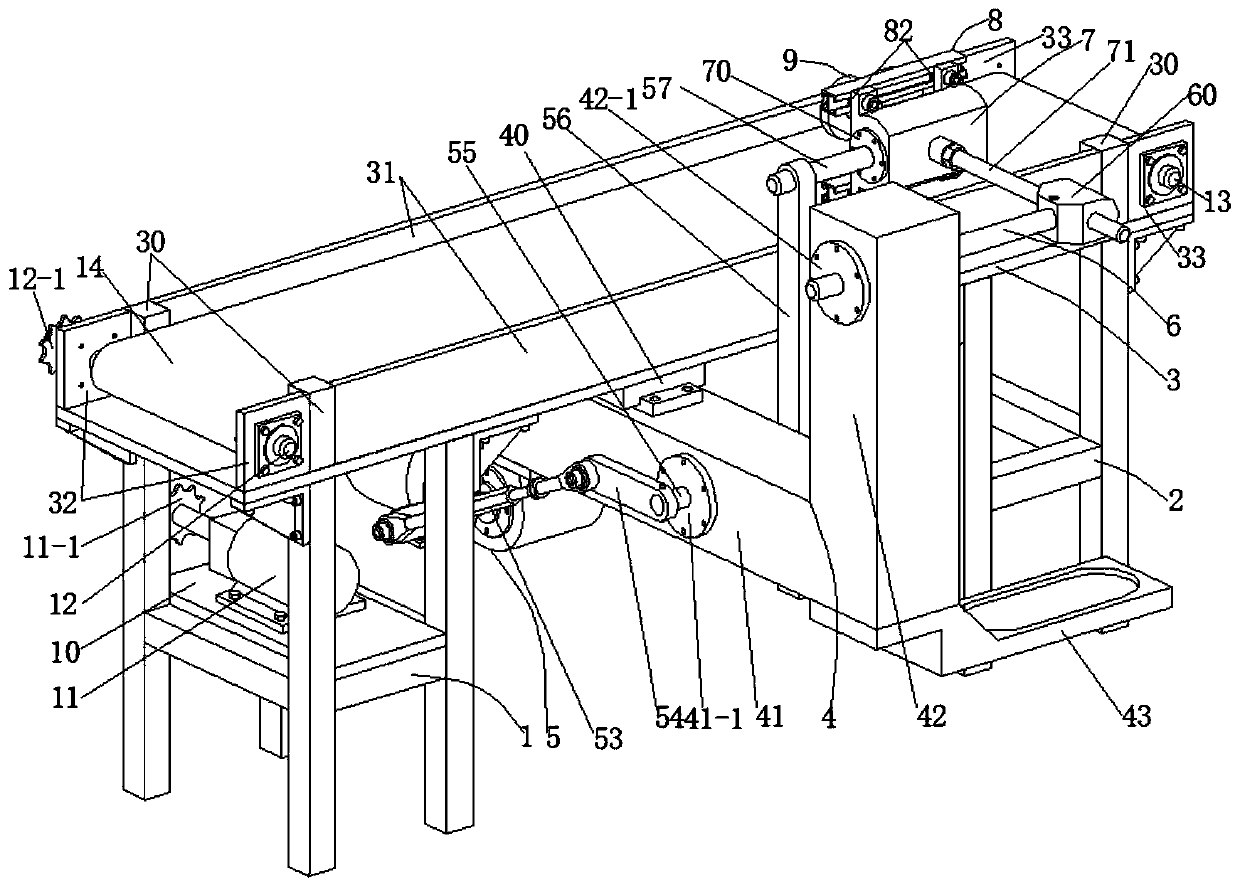

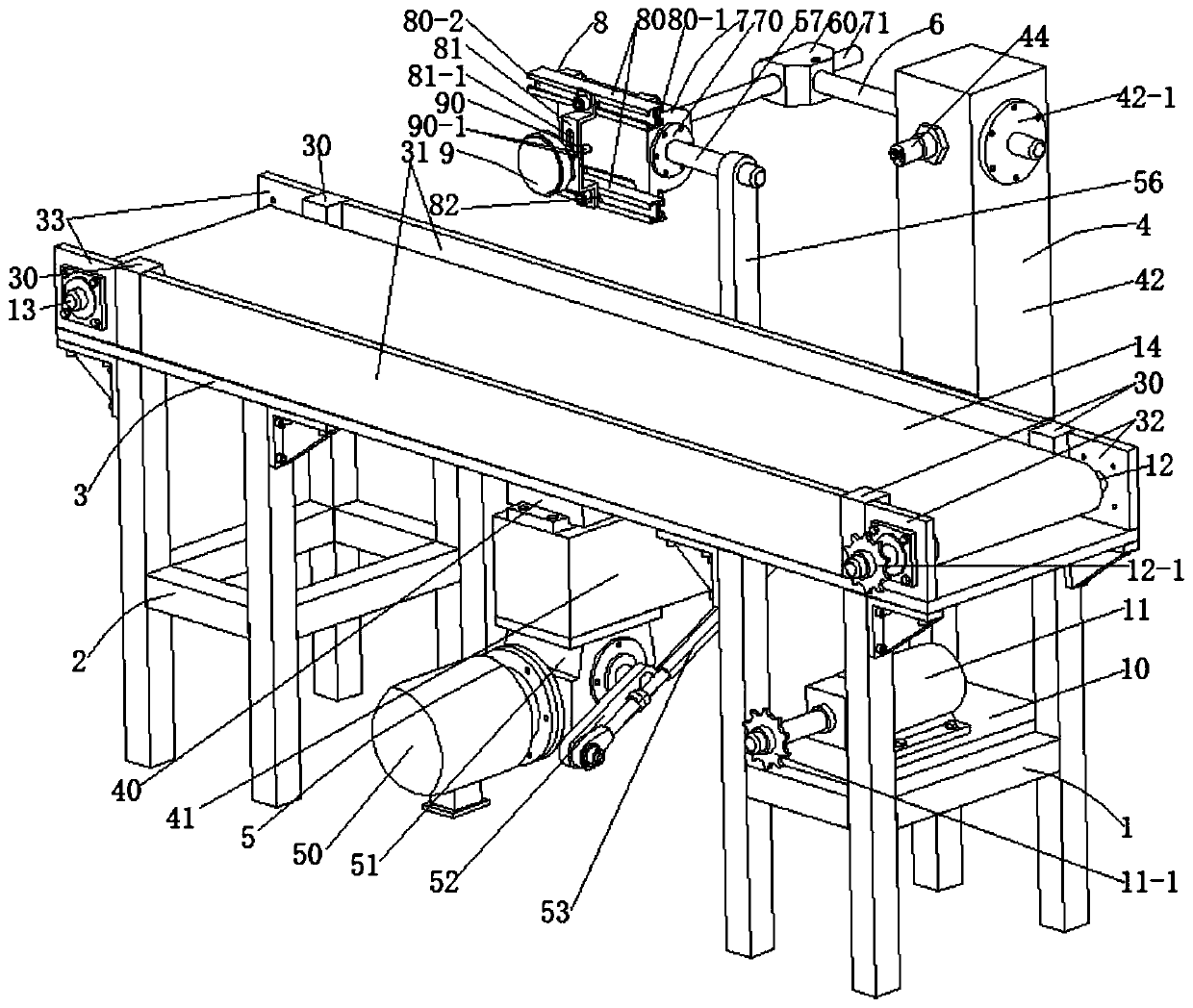

Embodiment 1

[0049] The production line automatically detects the signature device, and the box body packed with the product after being qualified by the detection device slides onto the conveyor belt 14 from the detection device, and the detection device sends a qualified signal to the servo motor 2 50, and the servo motor 1 11 The output shaft drives the first sprocket 11-1 to rotate, and the first sprocket 11-1 drives the second sprocket 12-1 to rotate with the driving roller 12 through the chain, and the driving roller 12 drives the conveyor belt 14 between the driving roller 12 and the driven roller 13 Movement, the casing that product is housed on the conveyer belt 14 is transported forward, when the photoelectric sensor 44 on the vertical frame 42 sidewalls detects the casing that product is housed, controls servomotor-11 deceleration to stop now, Make the casing that product is housed stop on the side of seal body 9, servomotor 2 50 rotates simultaneously, make the output shaft of r...

Embodiment 2

[0051] On the basis of Embodiment 1, the lower end of the support plate 3 is provided with a guide rail 34 in parallel, the "L" frame 4 is welded by a horizontal frame 41 and a vertical frame 42, and the upper arm of the horizontal frame 41 is provided with a There is a slide block 40, and the slide block 40 is slidably connected with the guide rail 34, realizing the drive mechanism 5 connected with the "L" frame 4, the driven shaft 6, the base block 7, the adjustment frame group 8 and the stamp body 9 on the conveyor belt 14 The position adjustment in the conveying direction can not only adapt to different inspection production lines, but also adapt to different sizes of boxes detected by the inspection device, which is convenient and reliable.

[0052] The upper end of the support plate-3 is provided with two groups of uprights 30, two of each group, which ensures the limit of the movement of the conveyor belt 14, thereby ensuring that the box body with the product is stopped...

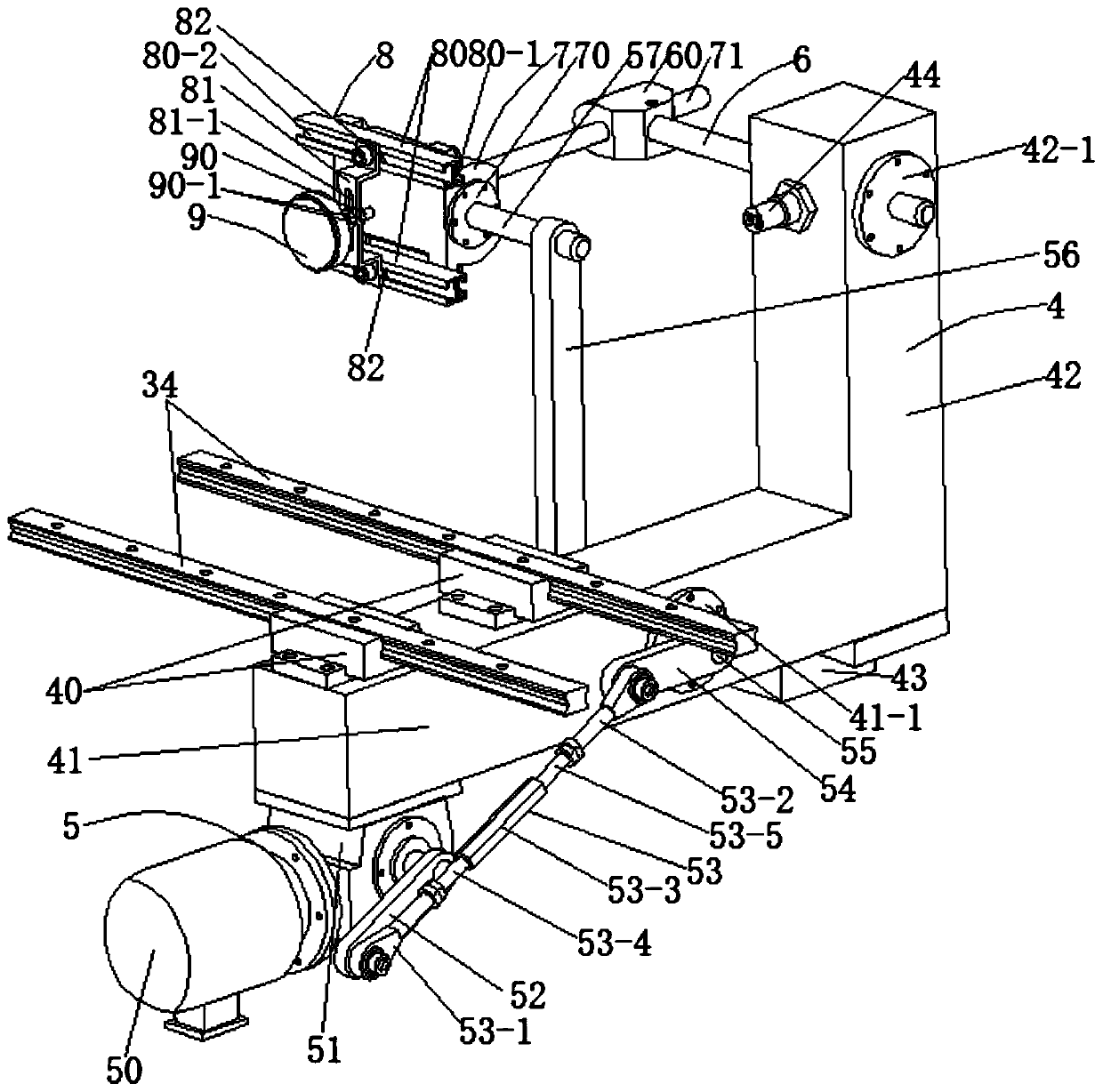

Embodiment 3

[0055]On the basis of embodiment 1, the drive mechanism 5 is composed of servo motor two 50, reducer 51, connecting rod one 52, telescopic connecting rod 53, connecting rod two 54, rotating shaft one 55, connecting rod three 56 and rotating shaft two 57 Composition, the servo motor 2 50 is connected with the reducer 51, the reducer 51 is tightly connected with the bottom of the horizontal frame 41, one end of the connecting rod 52 is coaxially connected with the output shaft of the reducer 51 through a key, and the connecting rod 1 The other end of 52 is hinged with one end of telescopic connecting rod 53, the other end of telescopic connecting rod 53 is hinged with one end of connecting rod two 54, the other end of connecting rod two 54 is coaxially connected with one end of rotating shaft one 55 through a key, and said rotating shaft one 55 is connected with the bearing Sleeve 1 41-1 is connected by rolling bearing, the other end of rotating shaft 1 55 is coaxially connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com