Multi-directional flexible loading integral forming device and method for special-shaped multi-way joints

A multi-pass joint, integral forming technology, applied in forging/pressing/hammer devices, metal processing equipment, forging presses, etc., can solve the problems of low mechanical properties, poor organizational uniformity, obvious texture tendency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Special-shaped bottom bracket joints are designed, and the five joint channels are respectively at angles of 30°, 30°, 0°, 45°, and 45° to the horizontal direction, and are distributed radially; the lengths of the channels are 60mm, 60mm, 80mm, 40mm, and 40mm; The wall thicknesses are 3mm, 2mm, 2mm, 1mm, 1mm; the outer diameters are φ40mm, φ40mm, φ60mm, φ50mm, φ50mm.

[0090] Step 1: Process a cylindrical billet with a diameter of 100 mm and a height of 76 mm by using a 7075 aluminum alloy commercially extruded bar, and heat it to 400° C. for 10 minutes by induction heating.

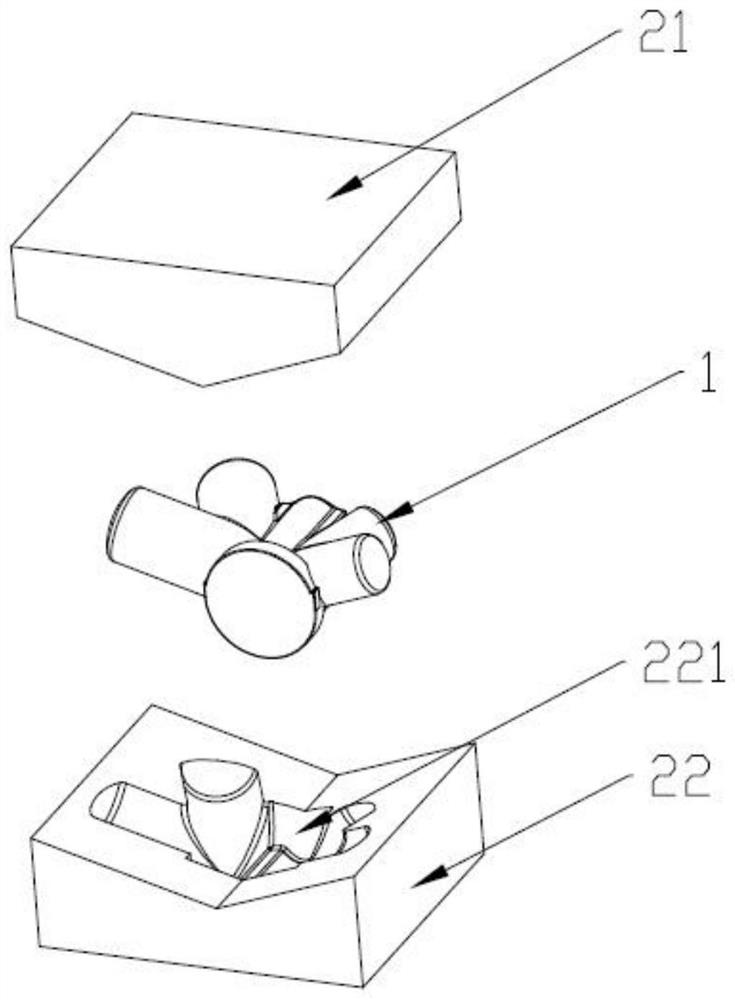

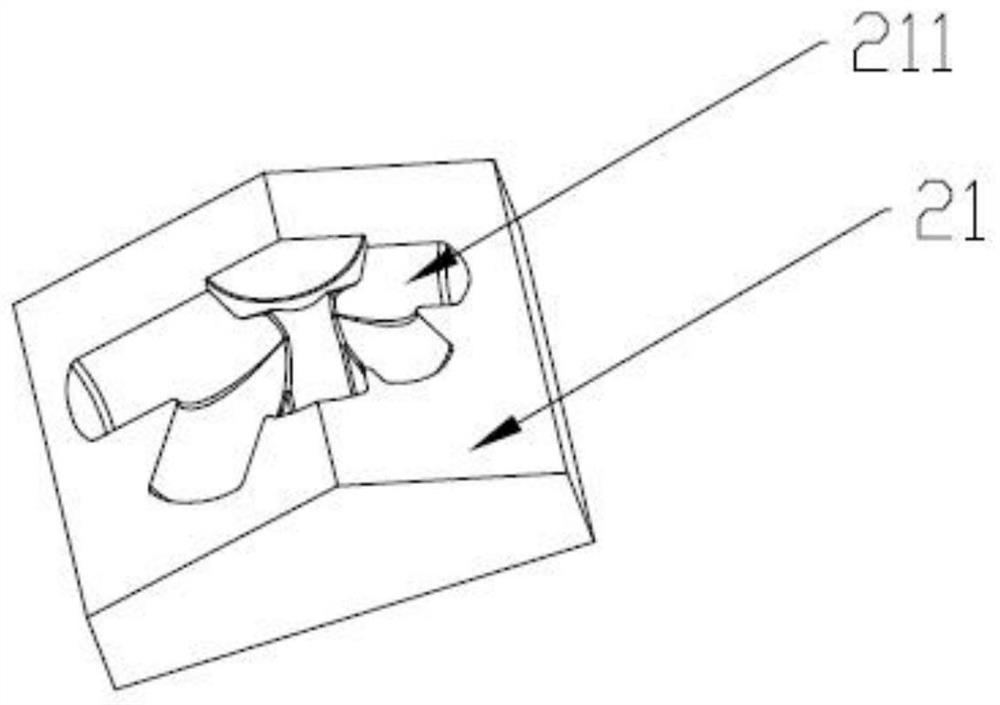

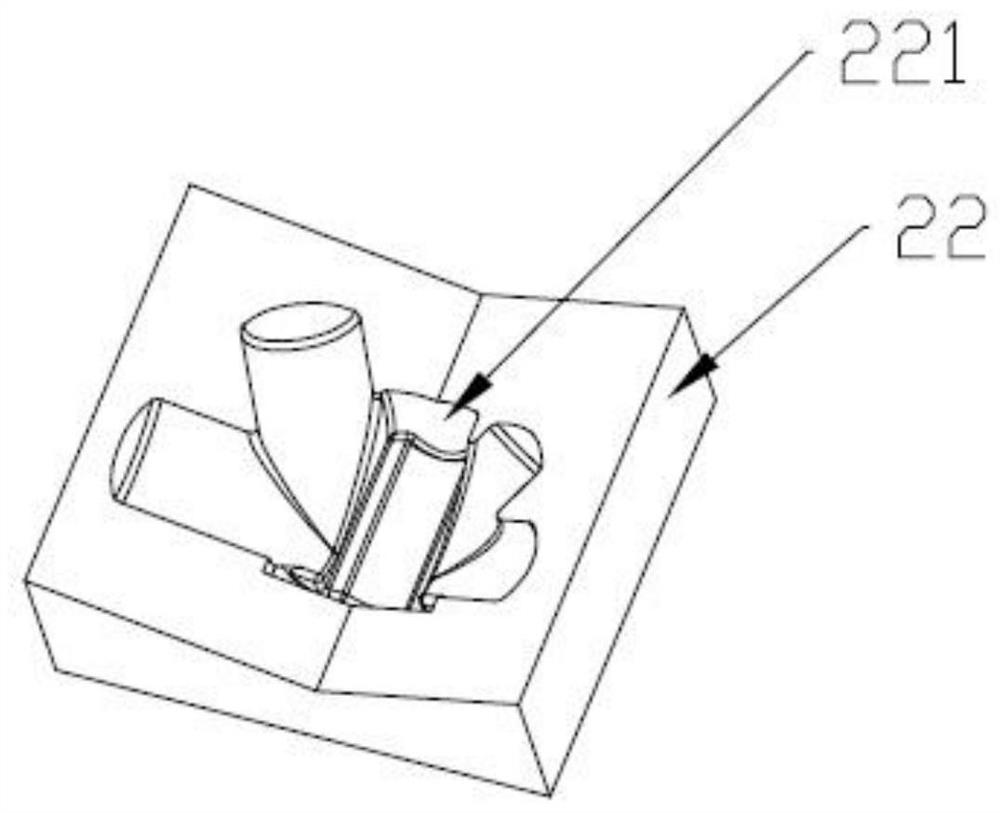

[0091] Step 2, processing the pre-forging die. The open die forging scheme is adopted to process punches, dies and inserts, and the pre-forging top punch 21 and pre-forging bottom die 22 are used in the insert splicing process, so that the pre-forging top punch 21 and pre-forging bottom die 22 After closing, the shape of the internal cavity is similar to that of the special-shaped bottom bracket ...

Embodiment 2

[0100] Special-shaped bottom bracket joints are designed, and the five joint channels are respectively at angles of 30°, 15°, 15°, 60°, and 60° to the horizontal direction, and are distributed radially; the lengths of the channels are 50mm, 50mm, 70mm, 40mm, and 40mm; The wall thicknesses are 2mm, 2mm, 3mm, 2mm, 3mm; the outer diameters are φ40mm, φ40mm, φ60mm, φ50mm, φ50mm.

[0101] Step 1: A cylindrical billet with a diameter of 100 mm and a height of 81 mm is processed by using AZ31 magnesium alloy commercial extruded bars, and heated to 420° C. for 10 minutes by induction heating.

[0102] Step 2, processing the pre-forging die. The open die forging scheme is adopted to process punches, dies and inserts, and the pre-forging top punch 21 and pre-forging bottom die 22 are used in the insert splicing process, so that the pre-forging top punch 21 and pre-forging bottom die 22 After closing, the shape of the internal cavity is similar to that of the special-shaped bottom brack...

Embodiment 3

[0111] Design special-shaped tee joints, the three joint channels are at angles of 30°, 0°, and 45° to the horizontal direction; the channel lengths are 60mm, 80mm, and 40mm; the wall thicknesses are 3mm, 2mm, and 1mm; the outer diameters are φ40mm, φ60mm, φ50mm.

[0112] Step 1: Use TC4 titanium alloy to process a cylindrical blank with a diameter of 90mm and a height of 63mm, and heat it to 1000° C. for 10 minutes by induction heating.

[0113] Step 2, processing the pre-forging die. The open die forging scheme is adopted to process punches, dies and inserts, and the pre-forging top punch 21 and pre-forging bottom die 22 are used in the insert splicing process, so that the pre-forging top punch 21 and pre-forging bottom die 22 After closing, the shape of the internal cavity is similar to the shape of the special-shaped tee joint. It is required that the blank can be used to forge the base part of the special-shaped tee joint and the subsequent protruding part for forming ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com