Feed stirring device for poultry breeding

A feed mixing and poultry technology, applied in feed, mixer accessories, applications, etc., can solve problems such as low mixing efficiency, insufficient feed mixing, malnutrition, etc., achieve good mixing effect and prevent feed splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

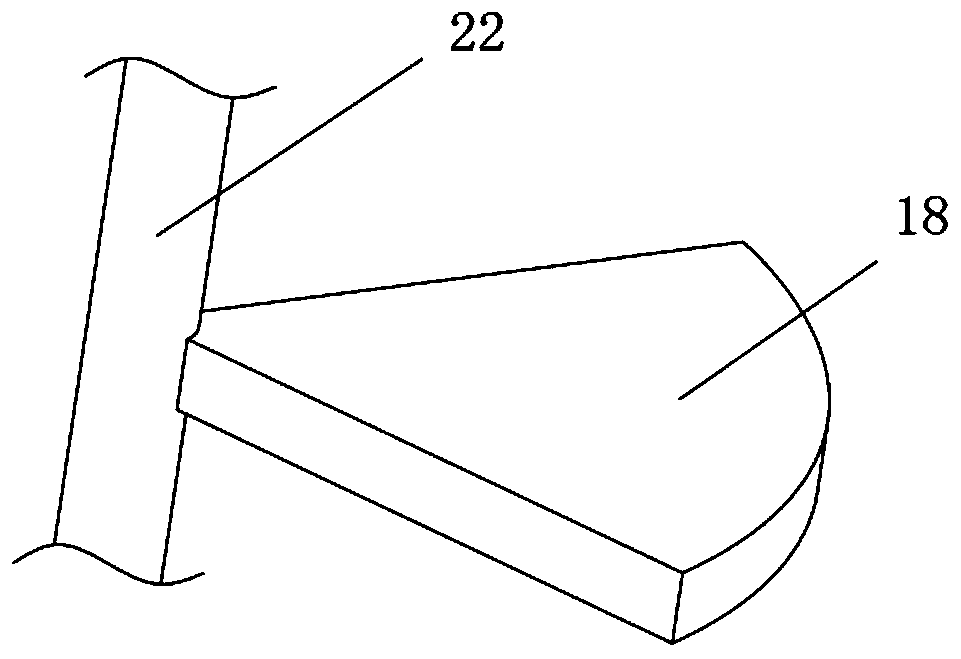

[0023] see Figure 1~4 , in an embodiment of the present invention, a feed stirring device for poultry breeding, comprising a stirring chamber 1 and a stirring mechanism arranged on the stirring chamber 1, the stirring chamber 1 is provided with a feed inlet 12 and a feed outlet 9, so The stirring mechanism includes a telescopic rod 15 and a drive motor 17. A vertical plate 13 is fixedly installed on the top of the stirring chamber 1, and a chute is provided on the vertical plate 13, and a slide block 14 is provided for sliding in the chute. The fixed end of rod 15 is fixedly installed on the slide block 14, and the free end of telescopic rod 15 is fixedly connected with drive motor 17, and first spring 16 is sleeved on telescopic rod 15, and the top of described mixing chamber 1 is positioned at drive motor The bottom of 17 is provided with circular opening 23, and the output end of driving motor 17 is fixedly installed with stirring shaft 22, and stirring shaft 22 is provide...

Embodiment 2

[0031] see Figure 4 , in order to reduce the friction between the slider 14 and the vertical plate 13, so as to ensure the vibration effect of the drive motor 17, this embodiment is further improved on the basis of embodiment 1. Compared with embodiment 1, the main difference That is: the upper side and the lower side of the slider 14 are rollingly connected between the roller 21 and the vertical plate 13, the left side and the right side of the slider 14 are respectively rollingly connected between the ball 3 and the vertical plate 13, and the ball 3 lowers the sliding The friction between the block 14 and the vertical plate 13 also plays a role in positioning the slide block 14, ensuring that the slide block 14 will not shake when the telescopic rod 15 is compressed and stretched.

[0032] The working principle of this embodiment is: the sliding block 14 is rolled and connected between the vertical plate 13 through the ball 3 and the roller 21, the friction between the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com