Blast furnace circulating cooling water flow regulation and control method

A technology of circulating cooling water and flow regulation, which is applied in the direction of non-electric variable control, cooling device, control/regulation system, etc., and can solve problems such as difficult to summarize the mechanism model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

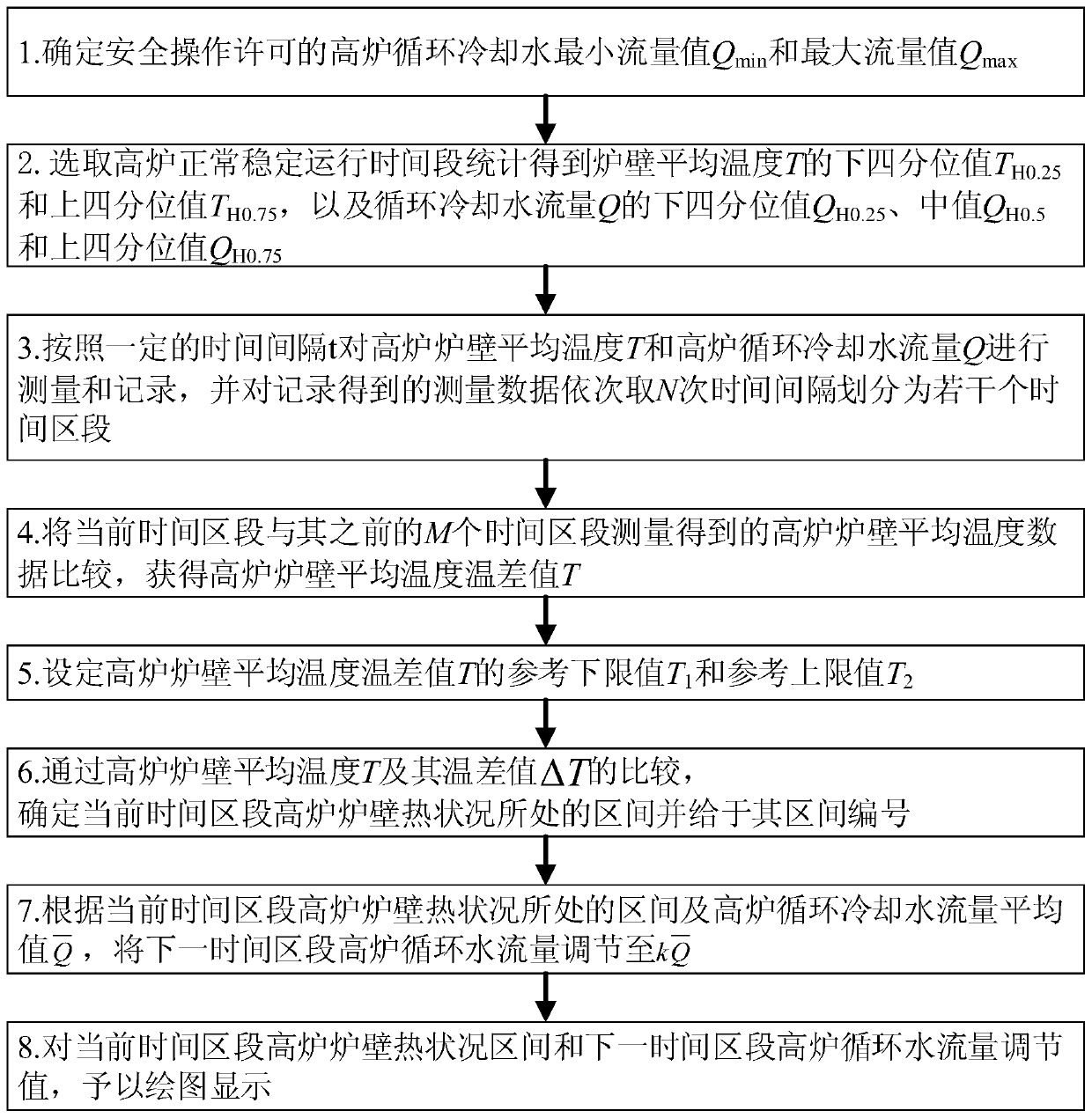

[0062] see figure 1 , is a flow chart of the inventive method, and it comprises the following steps:

[0063] Step 1. According to the process design and equipment selection information, determine the minimum flow value Q of blast furnace circulating cooling water permitted for safe operation min and the maximum flow value Q max .

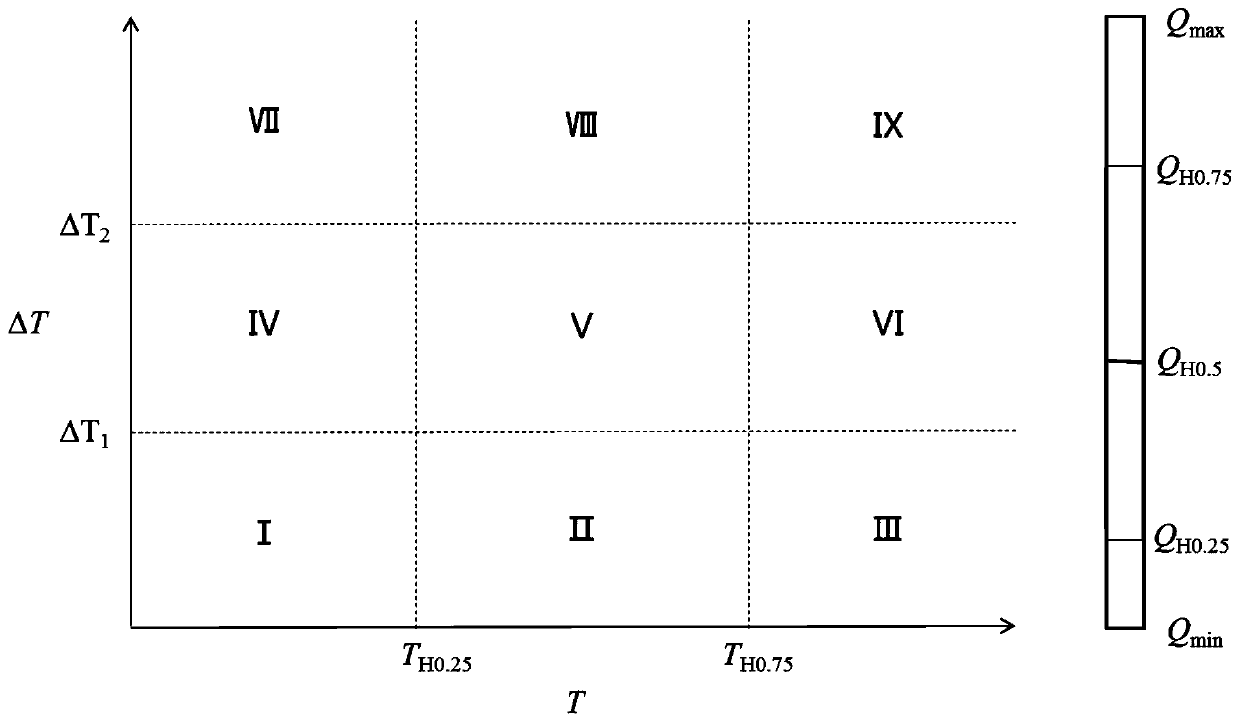

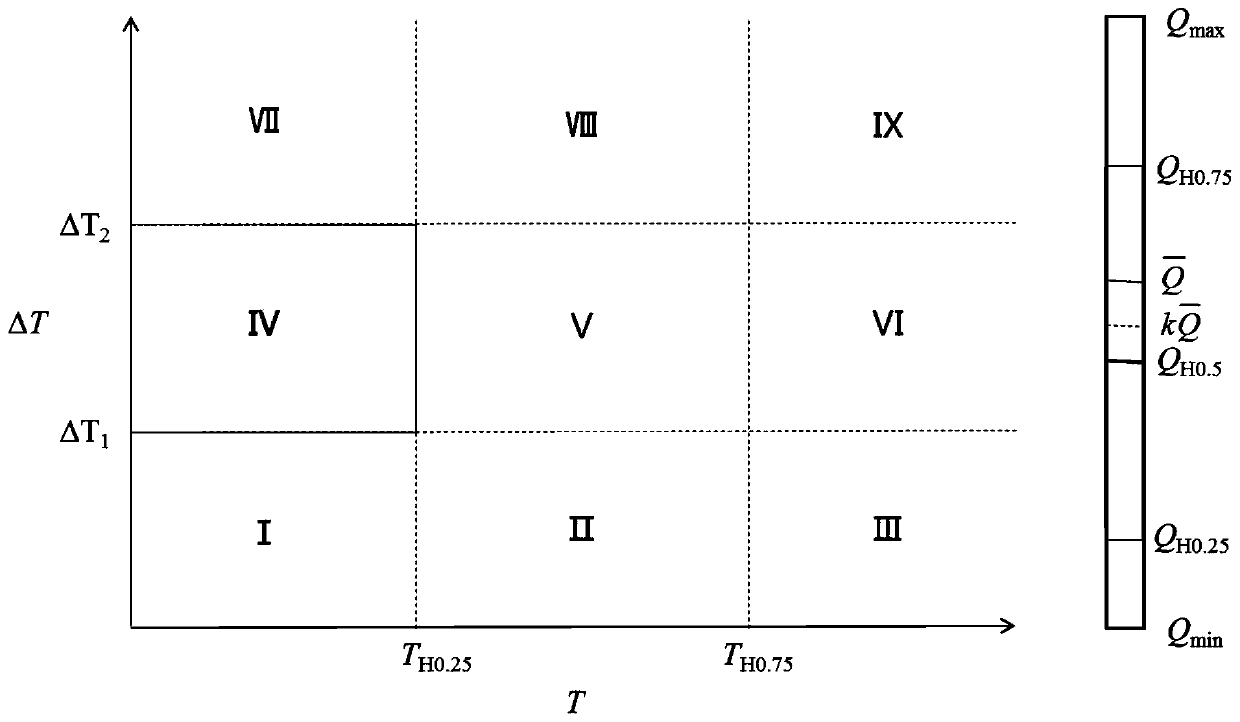

[0064] Step 2. According to the historical operation data of the blast furnace, select the normal and stable operation period of the blast furnace to obtain the lower quartile value T of the average temperature T of the blast furnace wall H0.25 and the upper quartile T H0.75 , and the lower quartile value Q of the blast furnace circulating cooling water flow Q H0.25 , median Q H0.5 and the upper quartile Q H0.75 ;

[0065] The average temperature T of the furnace wall of the blast furnace is the average value of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com