A Wellbore Instability Loading Experiment Platform and Its Loading Method

A loading experiment and wellbore technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problem of not being able to simulate shear deformation, not considering factors such as casing internal pressure and temperature changes, and not considering cement environmental issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, the present invention will be further described:

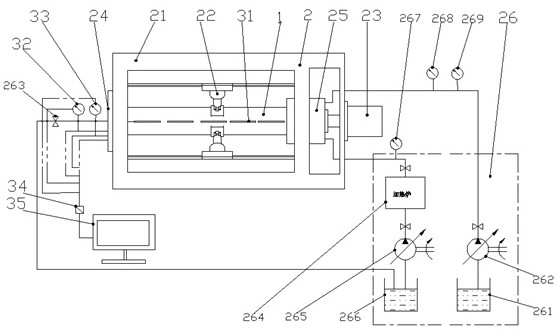

[0049] combine figure 1 As shown, a wellbore instability loading test platform includes a test specimen 1, a loading system 2 and a detection system. The loading system 2 is a device for applying load to the test specimen 1 , and the detection system is responsible for detecting changes in stress and strain, temperature and pressure of the test specimen 1 .

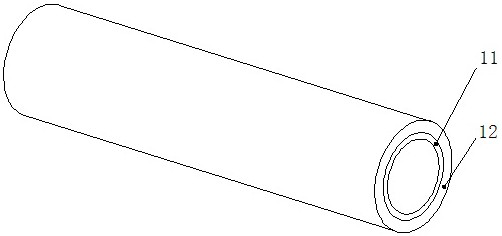

[0050] combine figure 2 As shown, the test specimen 1 includes a casing 11 and a cement sheath 12, and the cement sheath 12 and the casing 11 are cemented together to simulate the cement sheath poured in the gap between the outer wall of the oil and gas well casing and the formation to protect The role of casing.

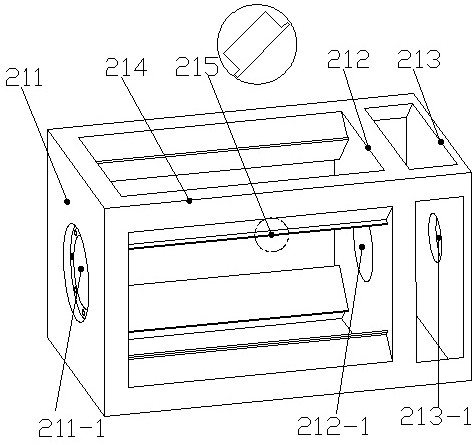

[0051] combine figure 1 As shown, the loading system 2 includes a loading platform 21 , a radial loading cylinder assembly 22 , an axial loading cylinder assembly 23 , a cover plate 24 , a fixing block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com