Tool assembly for improving universality of vibration test clamp and vibration test fixture

A vibration test and universal technology, applied in vibration test, measuring device, testing of machine/structural components, etc., can solve the problems affecting the development progress and increase the cost of equipment development, so as to shorten the development cycle, strengthen the practical value, guarantee the The effect of task progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

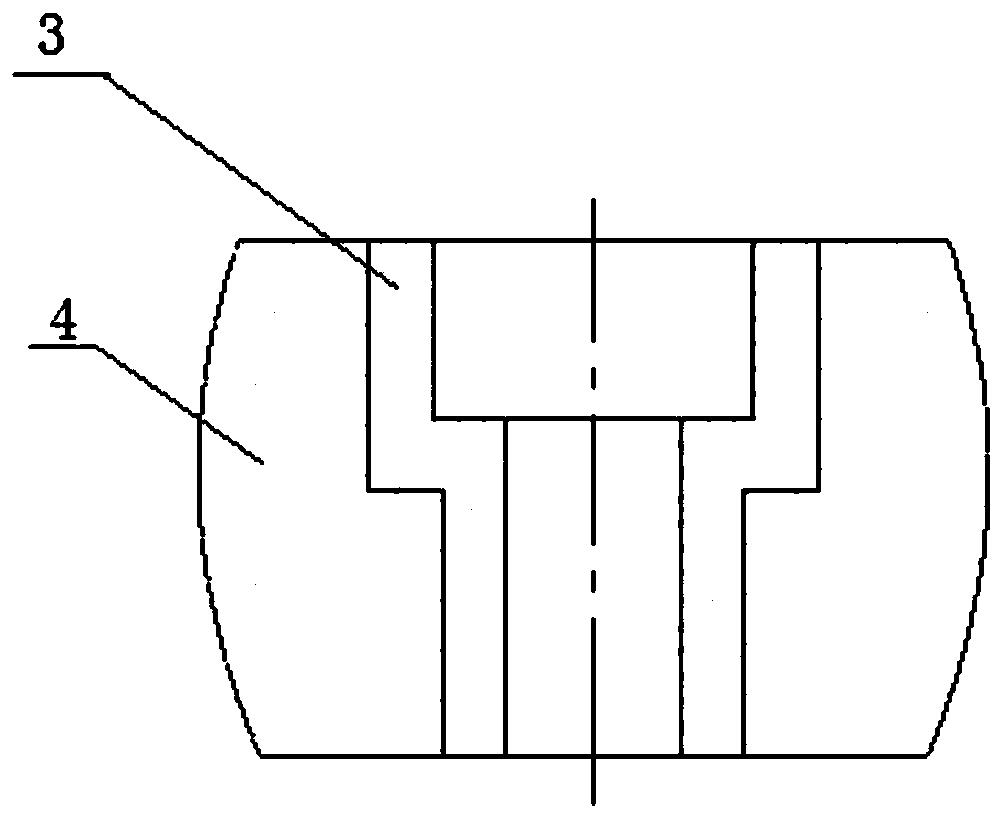

[0037] 1. Place the vibration test fixture 4 on the vibrating table, and roughly align the counterbore on the vibration test fixture 4 with the threaded hole on the vibrating table;

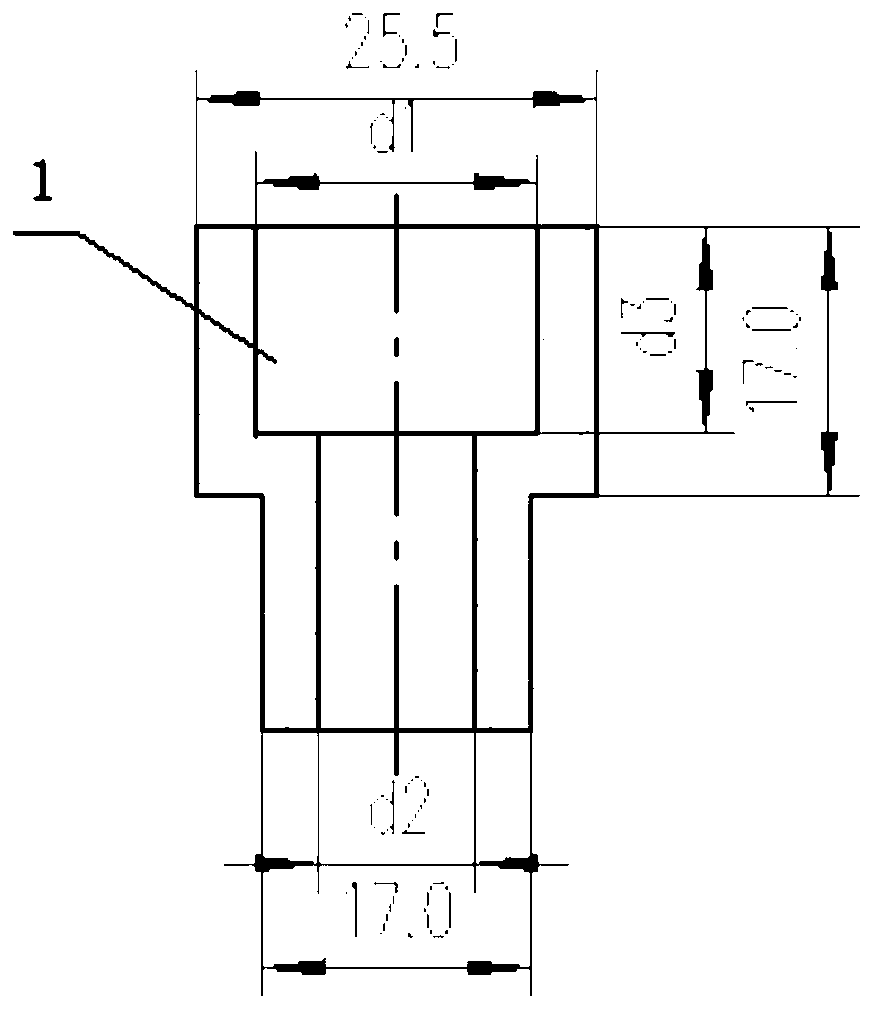

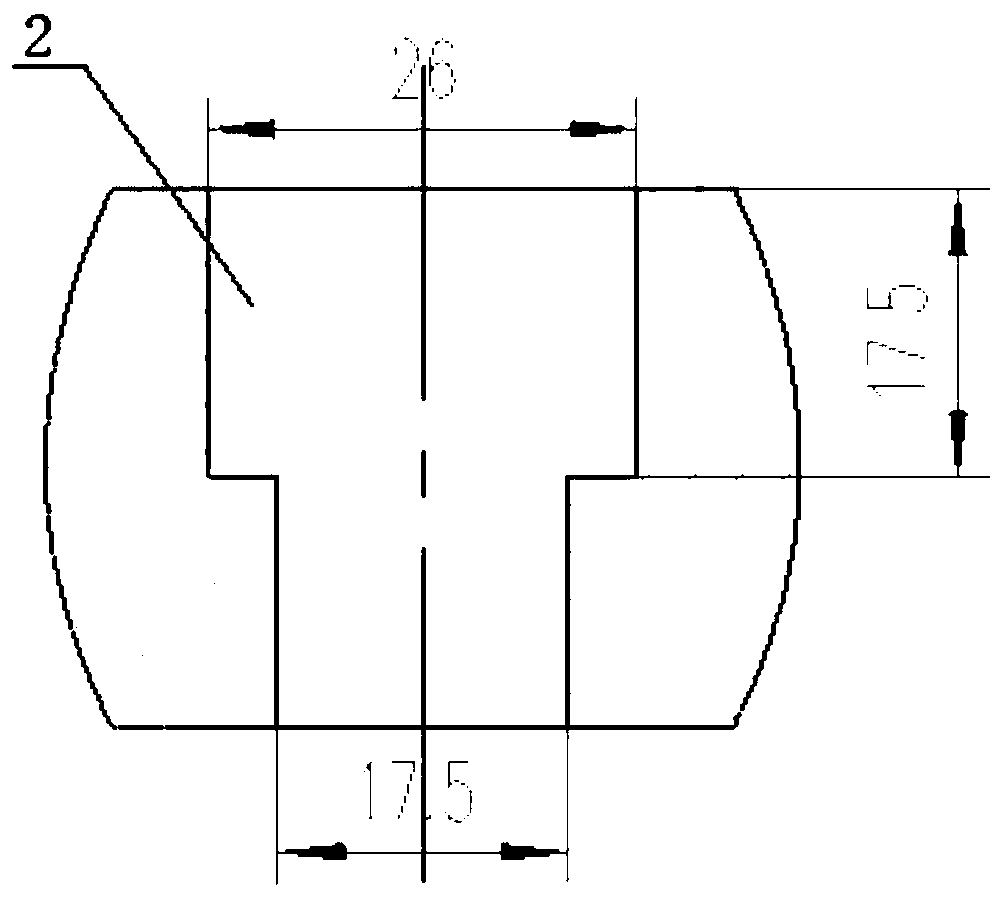

[0038] 2. Select the second tooling 3 with d1=18.0mm, d2=11.0mm, and d3=11.0mm, and put the second tooling 3 into each counterbore of the vibration test fixture 4 in turn;

[0039] 3. Place the M10mm hexagon socket head cap screws (not shown in the figure) in the second tooling 3 in sequence;

[0040] 4. Adjust the position of the vibration test fixture 4 so that the M10mm inner hexagon screw is aligned with the threaded hole on the vibration table;

[0041] 5. Use a hexagonal wrench to fasten each M10mm hexagonal screw to an appropriate torque to complete the rigid connection between the vibration test fixture and the vibrating table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com