Self-resetting weighing module

A weighing module and self-resetting technology, which is applied in the field of weighing, can solve the problems of not setting overload protection, affecting the weight of materials, and the automatic reset of modules is not in place, etc., to achieve diversified connection methods, wide selection, and convenient application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

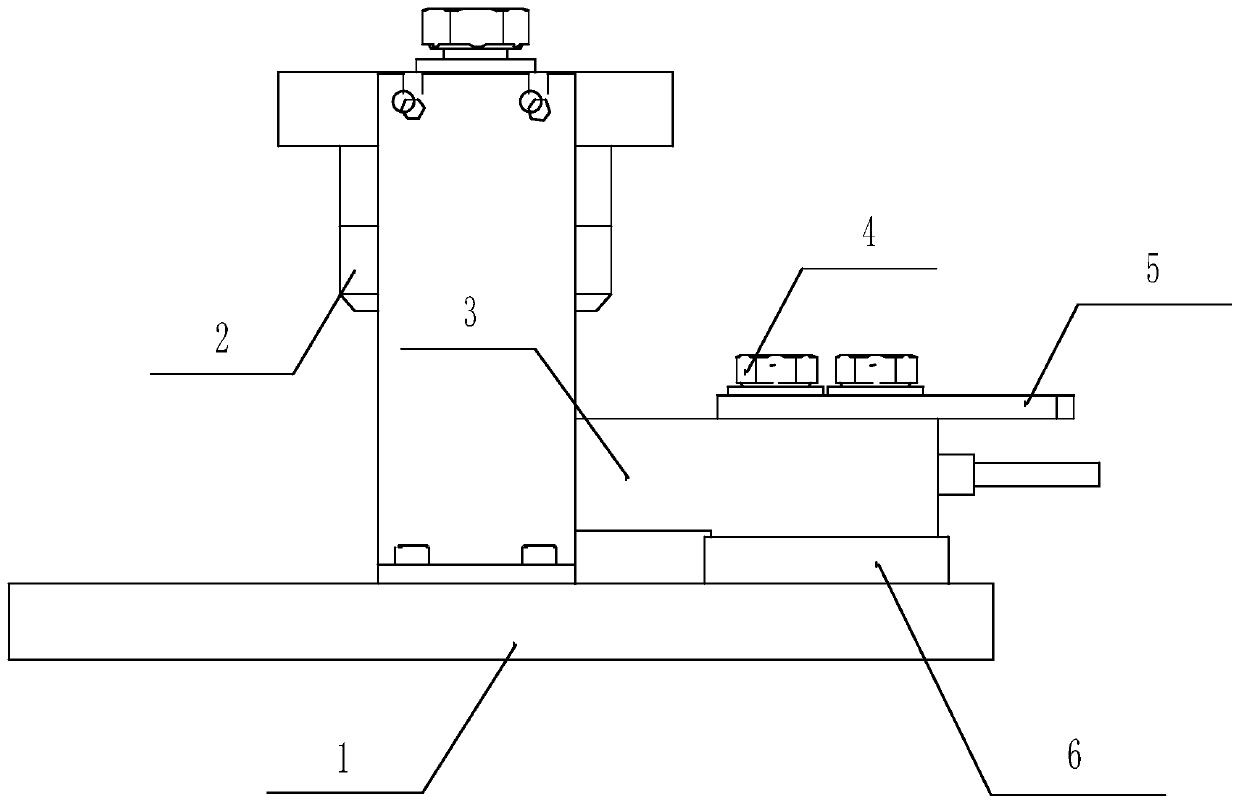

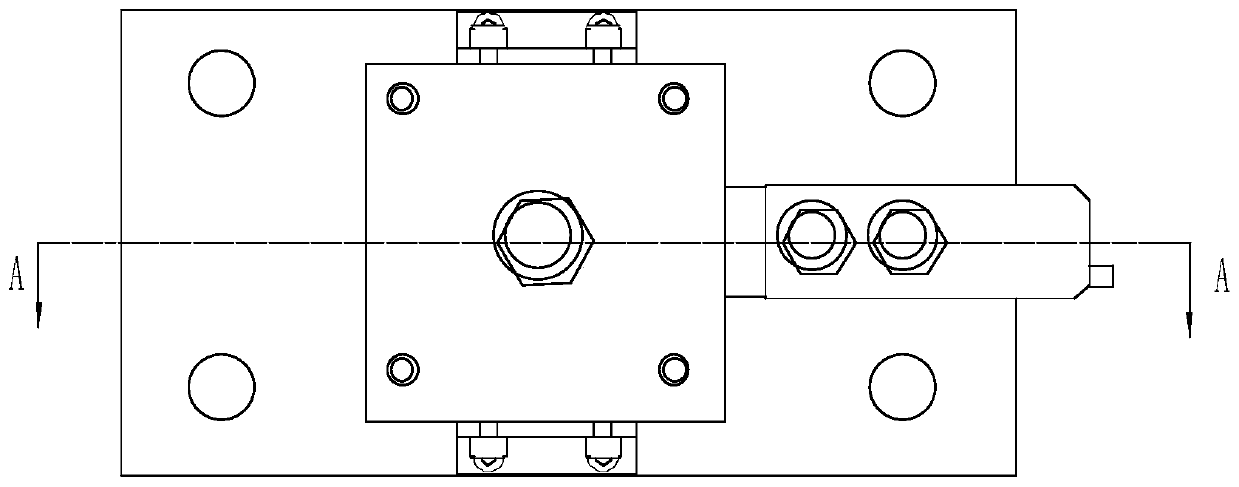

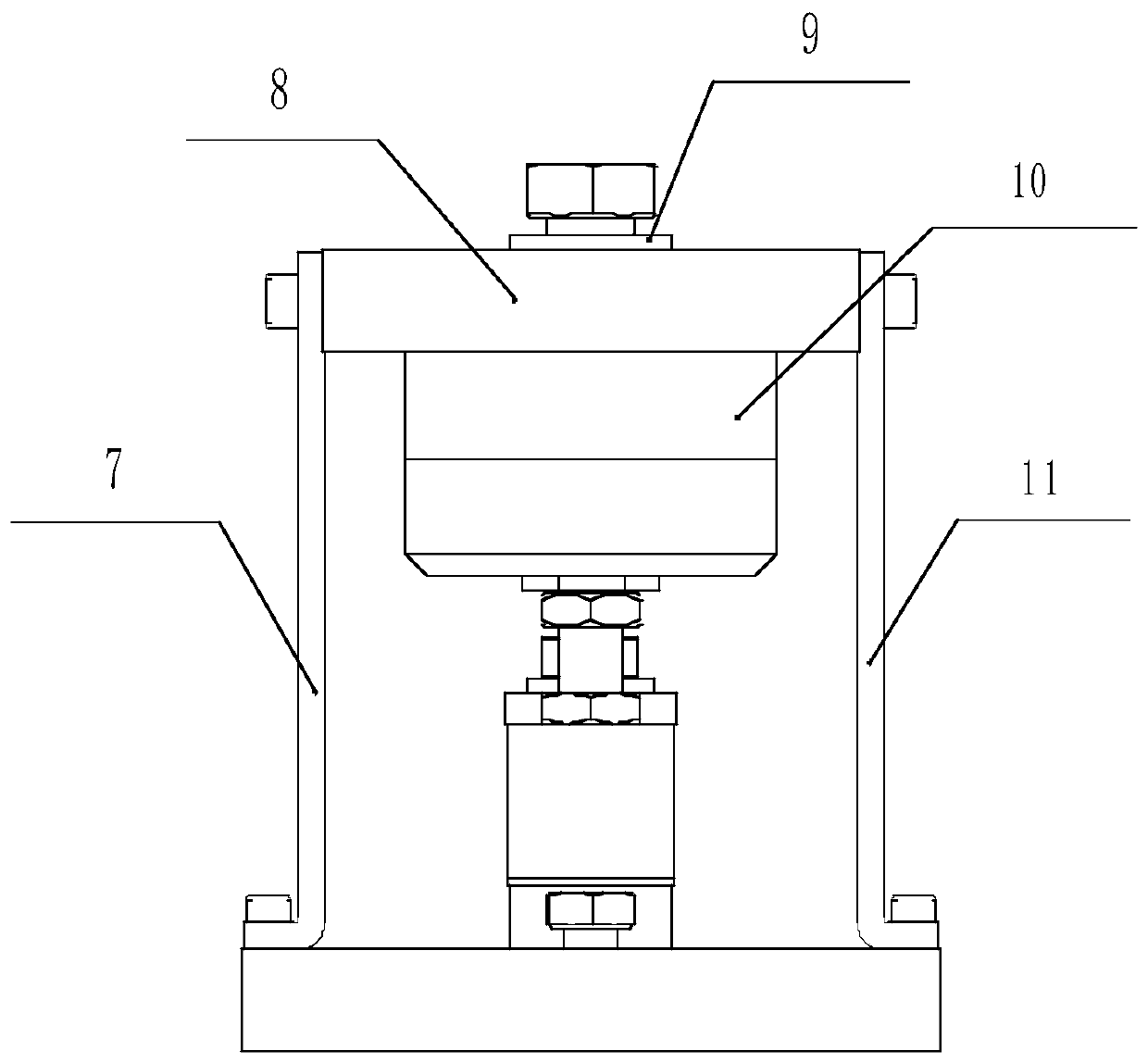

[0029] A self-resetting weighing module, characterized in that it includes a bottom plate 1, a load-bearing bottom block 2, a sensing element 3, bolts 4, a wire guard 5, a spacer 6, a rear support plate 7, a top plate 8, and a gasket 9. Loading top block 10, front support plate 11, positioning pin 12, lower adjusting nut 13, outer hexagonal high-strength bolt 14, height limit rod 15, upper adjusting nut 16 and steel ball 17, the pad 6 is installed on On the top surface of the bottom plate 1, the sensing element 3 is installed on the top surface of the pad 6, and the wire guard 5 is installed on the top surface of the sensing element 3 through the bolt 4 and the washer 9, and the described Both the rear support plate 7 and the front support plate 11 are fixedly mounted on the top surface of the base plate 1, the top plate 8 is respectively fixedly mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com