Slide-type drive shaft for large-swing-angle dustproof sleeve

A technology of dust-proof boot and sliding type, which is applied in the direction of sliding coupling, shaft coupling, elastic coupling, etc., can solve the problems of dust-proof boot rupture, shortening the service life of the drive shaft, oil leakage, etc., and achieves Effects of improving service life, reducing expansion and contraction, and reducing cracking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

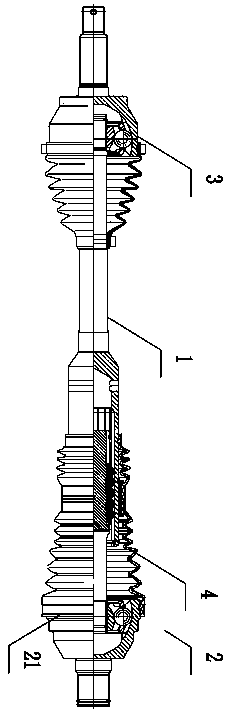

[0018] The present invention will be further described below in conjunction with the accompanying drawings: as shown in the figure, the sliding drive shaft with a large swing angle dust cover includes an intermediate shaft 1 and a first dust cover 4, and one end of the intermediate shaft is provided with a The movable end universal joint 2 is slidably connected in the axial direction of the shaft, and the other end is provided with a fixed end universal joint 3. The movable end universal joint is movably connected with the intermediate shaft in the axial direction. The knuckle includes a housing 21, and also includes a sliding member 5, which is slidably arranged on the peripheral outer wall of the intermediate shaft along the axial direction of the intermediate shaft, and one end of the first dust cover is connected to the sliding member. The other end is connected to the outer wall of the housing. In this way, when the universal joint at the moving end slides, the sliding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com