Construction process of underground drainage pipeline

A pipeline construction and underground drainage technology, which is applied in the sewer pipeline system, waterway system, water supply device, etc., can solve the problems of limited construction space, large occupied space, and extended construction period, so as to achieve low construction cost, fast construction progress, The effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

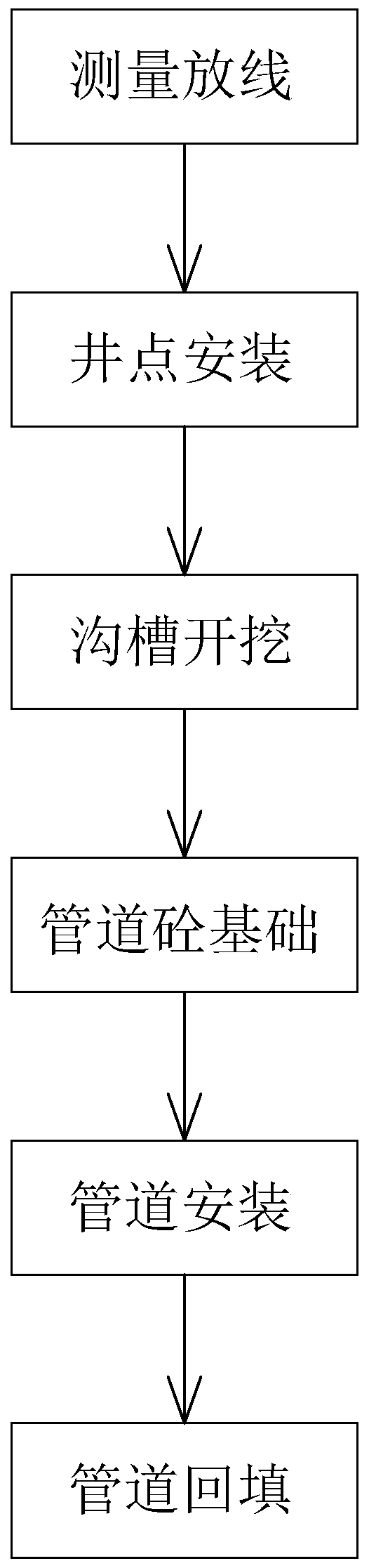

[0038] A kind of underground drainage pipeline construction technology, with reference to figure 1 , which includes the following steps:

[0039] S100. Surveying and setting out: Professional surveyors will conduct survey control and benchmarking point handover procedures in conjunction with the surveying unit. After piles are connected, surveyors will be organized to retest benchmarking points and wire points in a timely manner, and guide road centers, rainwater and sewage pipelines At the center, measure the temporary benchmarking point.

[0040] S200. Well point installation: The well point construction must be carried out in strict accordance with the operating procedures. When installing the well pipe, determine the reasonable embedding depth according to the measured original ground elevation, and use the water gun to punch the hole with a herringbone pole. The water gun should be vertical , Beware of hole collapse.

[0041] S201. Immediately after the standpipe is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com