Karst cave foundation pit supporting construction method

A foundation pit support and construction method technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve problems such as uneven force, foundation instability, collapse of karst cave roof, etc., and achieve the effect of reducing concrete filling and reinforcement The effect of increasing and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

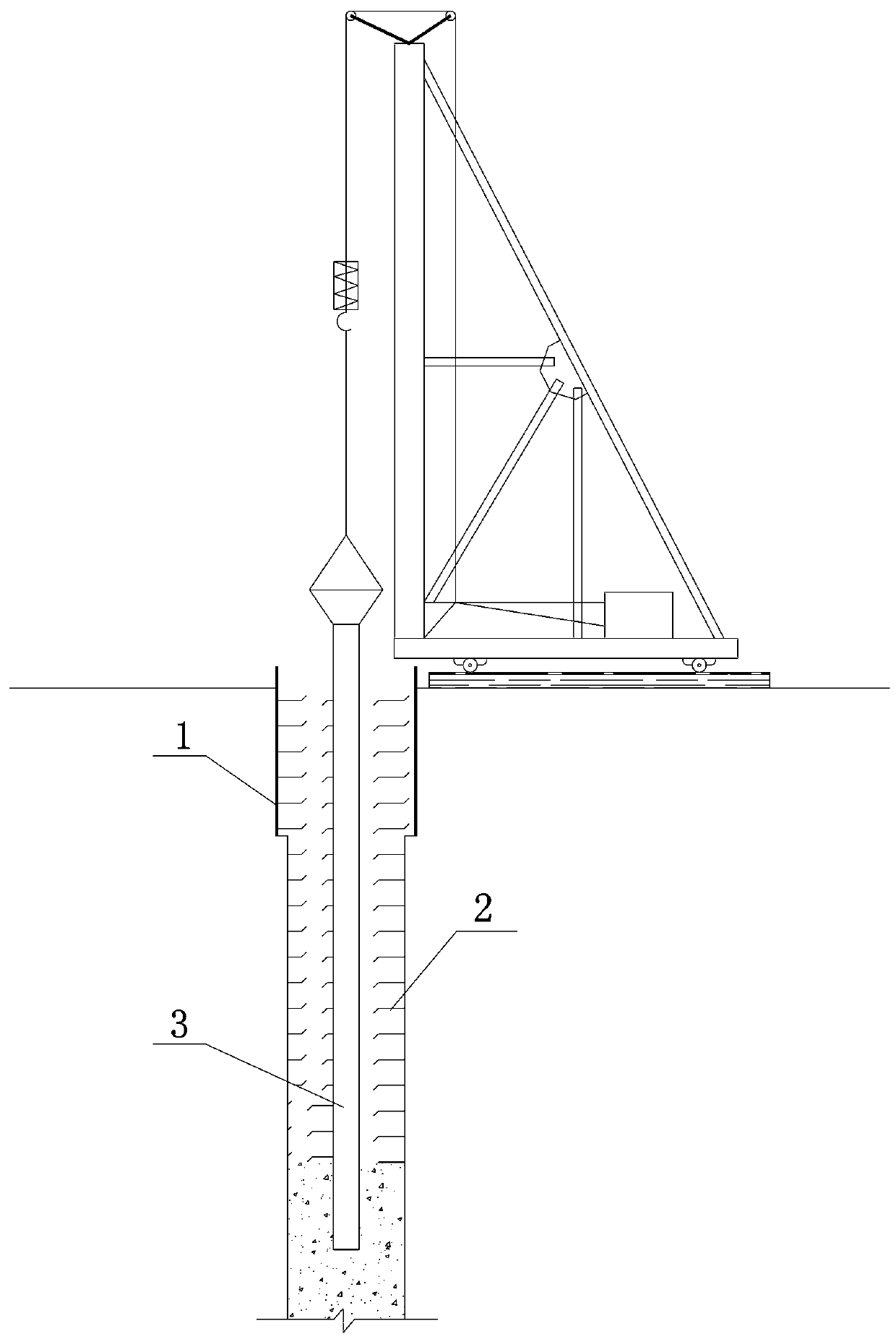

[0029] see figure 1 As shown, the present invention relates to a construction method for karst cave foundation pit support, comprising the following steps,

[0030] (a) According to the geological survey report, establish a physical model through BIM and design construction drawings;

[0031] (b) Excavation of the foundation pit shall be excavated by sloping, and the foundation pit shall be excavated according to the construction drawings;

[0032] (c) Measure and stake out, stake out and locate at the construction site according to the construction drawings, mark the pile position, and the pile position error is less than 20mm;

[0033] (d) Bury casing 1, bury casing 1 at the pile position, the deviation between the center of casing 1 and the pile location is less than 20mm, the inclination is less than 1%, the exposed ground is 100mm-200mm, and the buried depth of casing 1 is 1.0m-1.2m ;

[0034] (e) Prepare retaining mud, build mud pools, prepare drilling mud with water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com