Green environment-friendly packaging bag film

A green and environmentally friendly packaging bag technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve problems such as insufficient structure, poor user experience, and limited structural bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

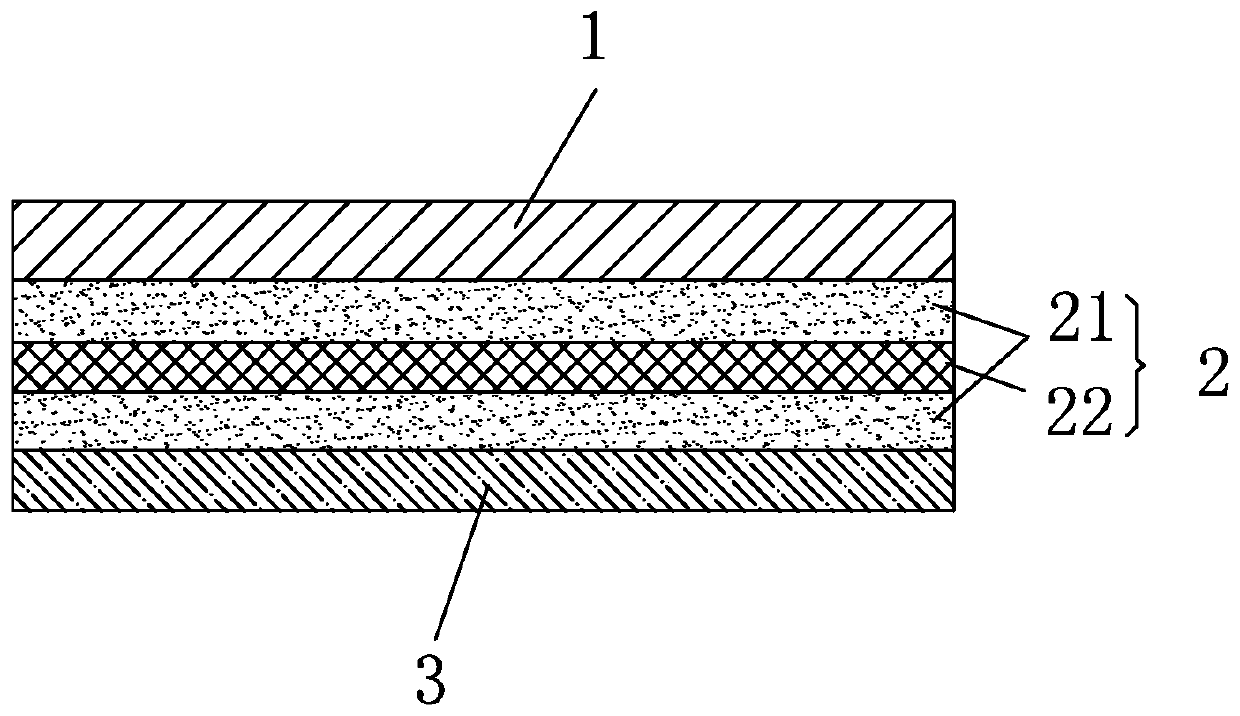

[0017] Such as figure 1 As shown, a green environmental protection packaging bag film, which includes successively stacking pe matte film layer 1, double-adhesive cotton paper layer 2 and pe base film layer 3, pe matte film layer 1 is arranged outside the packaging bag, pe The base film layer 3 is arranged inside the packaging bag, and the pe matte film layer 1 is formed by the pe material through the existing matte process, and the appearance is softer and more elegant. The double-adhesive tissue layer 2 includes several tissue layers 22 and the glue layer 21 coated on both sides of the tissue layer 22, and the pe matte film layer 1 and the pe base film layer 3 pass through the glue layer 21 and the tissue layer. 22 bonding, specifically can be bonded by hot pressing process.

[0018] In this way, the three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com