Raw material mixing equipment for 3D printing material production

A technology of 3D printing and mixing equipment, which is applied in the direction of metal processing equipment, 3D object support structure, additive processing, etc., can solve the problems of reduced mixing efficiency and increased mixing time, and achieve acceleration efficiency, increased mixing degree, and improved mixing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

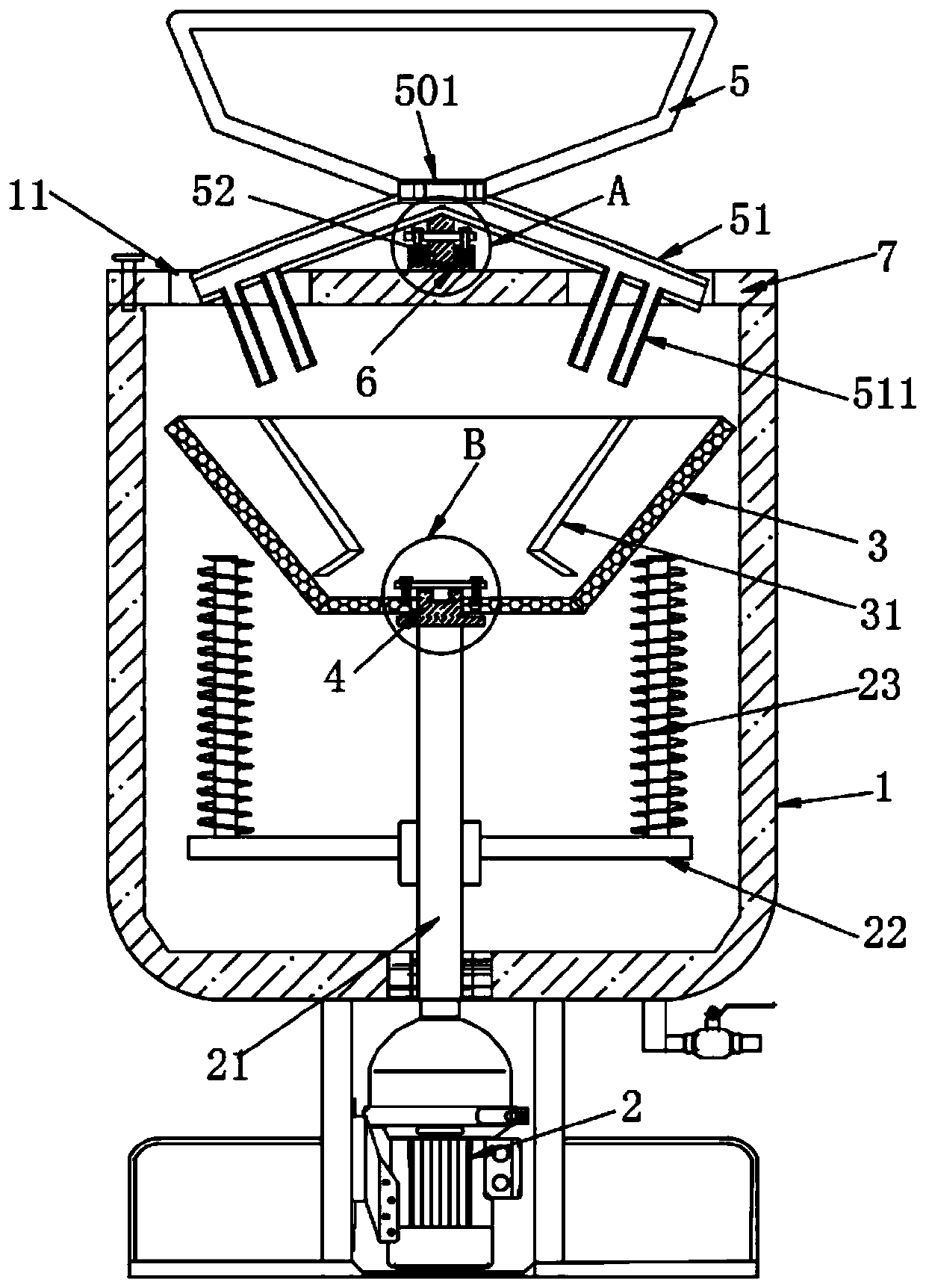

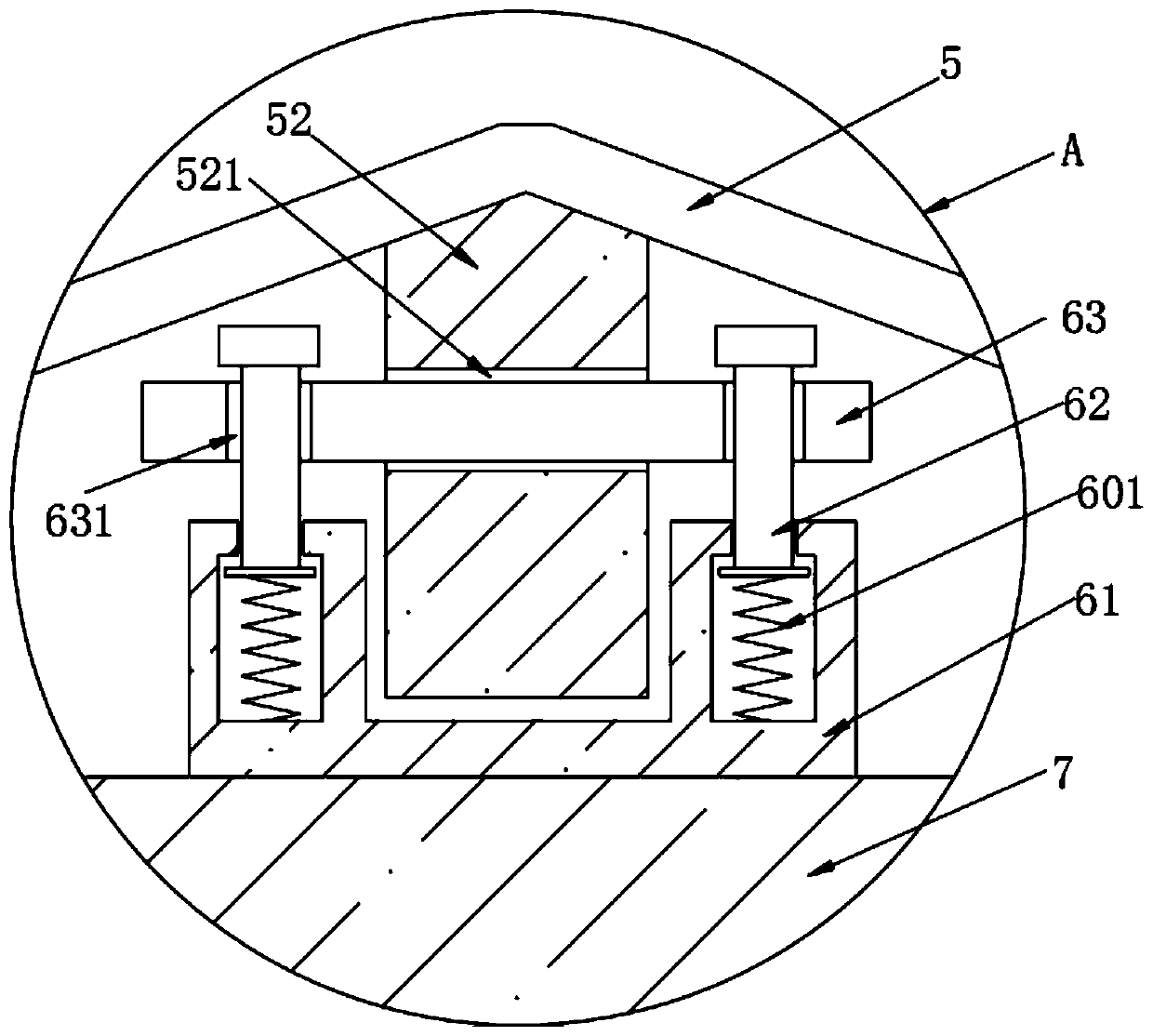

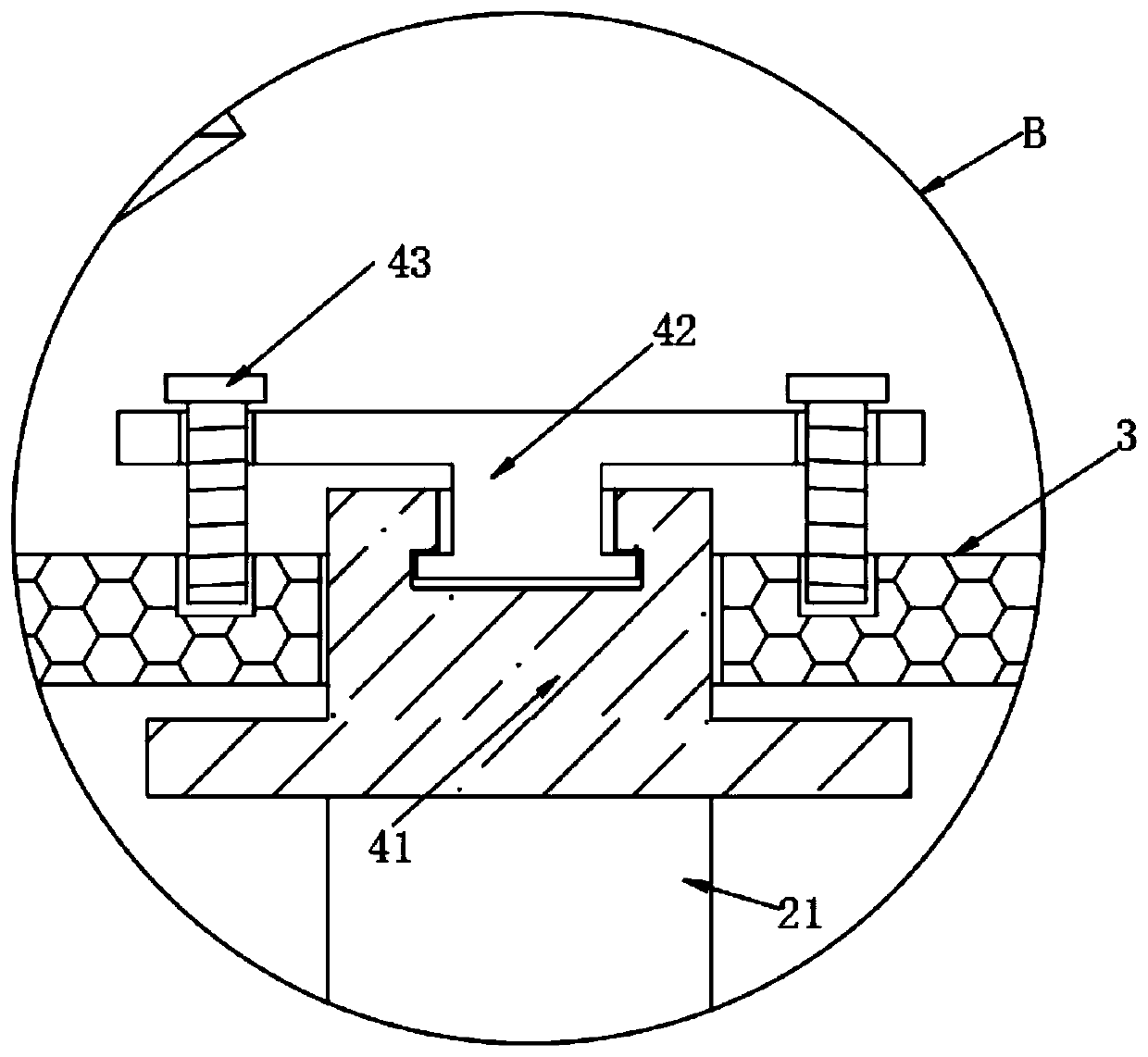

[0027] see Figure 1-5 , the present invention provides a technical solution: comprising a body 1 screwed and fixed with an upper cover 7, a motor 2 is fixedly connected to the bottom of the body 1, the motor 2 is electrically connected to an external power supply, and the output end of the motor 2 is fixedly connected to a connecting rod 21, The connecting rod 21 runs through the body 1, and the connecting rod 21 is fixedly connected with two installation rods 22, both of which are fixedly connected with the stirring roller 23, and the body 1 is rotatably connected with the mixing filter hopper 3, and the mixing filter hopper 3 passes through The mounting part 4 is detachably connected with the connecting rod 21, the mounting part 4 includes a positioning block 41 and a rotating block 42, the positioning block 41 is fixedly connected with the connecting rod 21, the positioning block 41 runs through the mixing filter 3, and is connected with the mixing filter 3 Sliding connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com