Monatomic catalyst prepared based on surface immobilizing method

A catalyst and atomic technology, applied in the field of preparation of metal single atom catalysts, to achieve the effects of high yield, cheap and easy-to-obtain raw materials, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

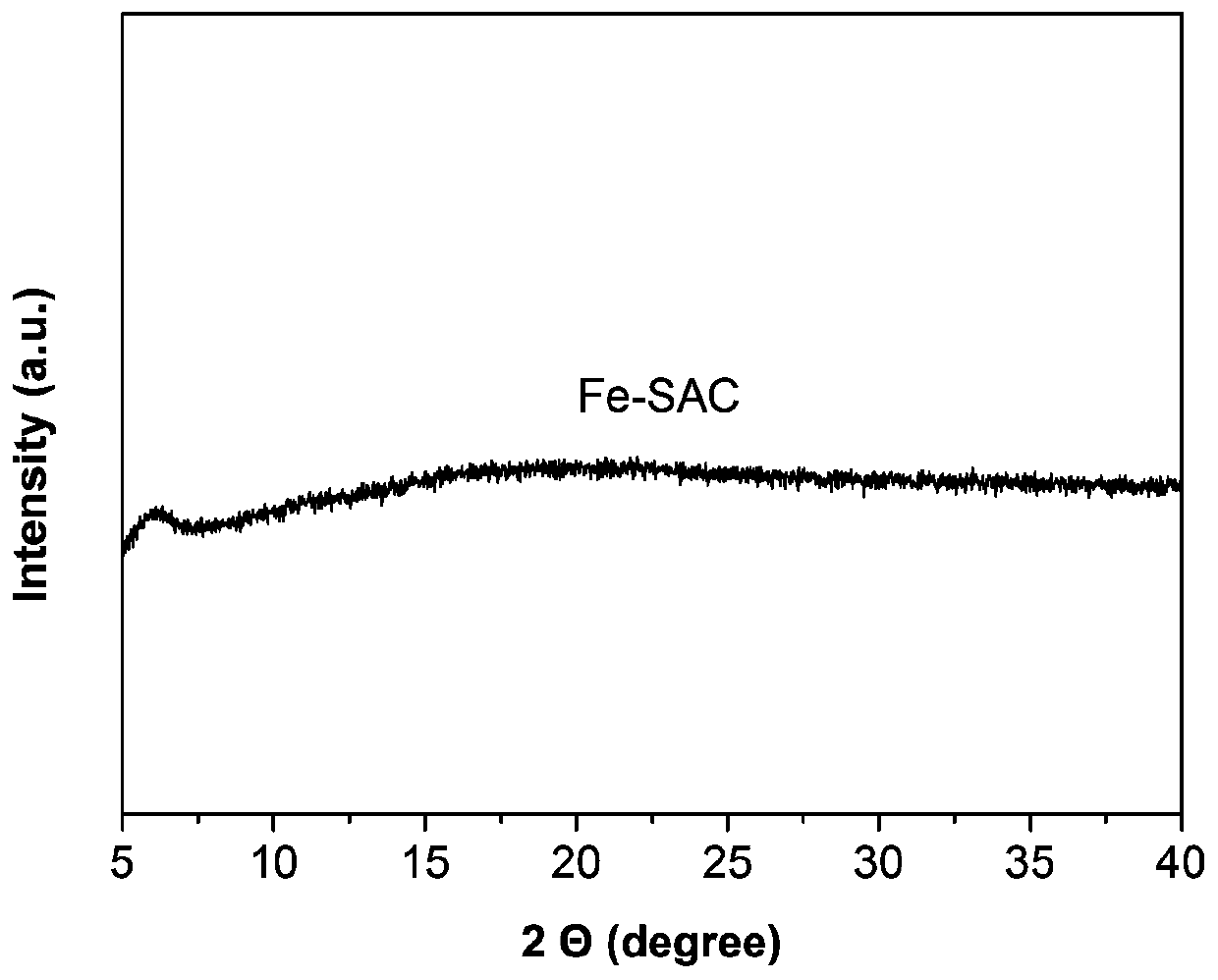

[0032] Preparation of Fe single atom

[0033] Add 40 mg of 1,3,5 trimesic acid, 200 mg of cobalt nitrate hexahydrate and 20 mg of bipyridyl iron into 150 ml of DMSO solution and ultrasonicate for 30 min at room temperature to fully dissolve the organic ligands and metal salts. Stir well and transfer to the reaction kettle. Use an oven to heat the reaction at a constant temperature of 90° C. for 2 days. A porous organometallic framework structure loaded with bipyridyl iron was obtained. Subsequently, the solvent is removed by centrifugation, washing, and vacuum drying, and the precursor is pulverized into powder and placed in a porcelain boat. The sample was calcined and pyrolyzed in a tube furnace filled with inert gas. The heating rate is 2°C / min, and the temperature is controlled below 400°C for 2 hours. Through the above steps, a pink powder is finally obtained.

Embodiment 2

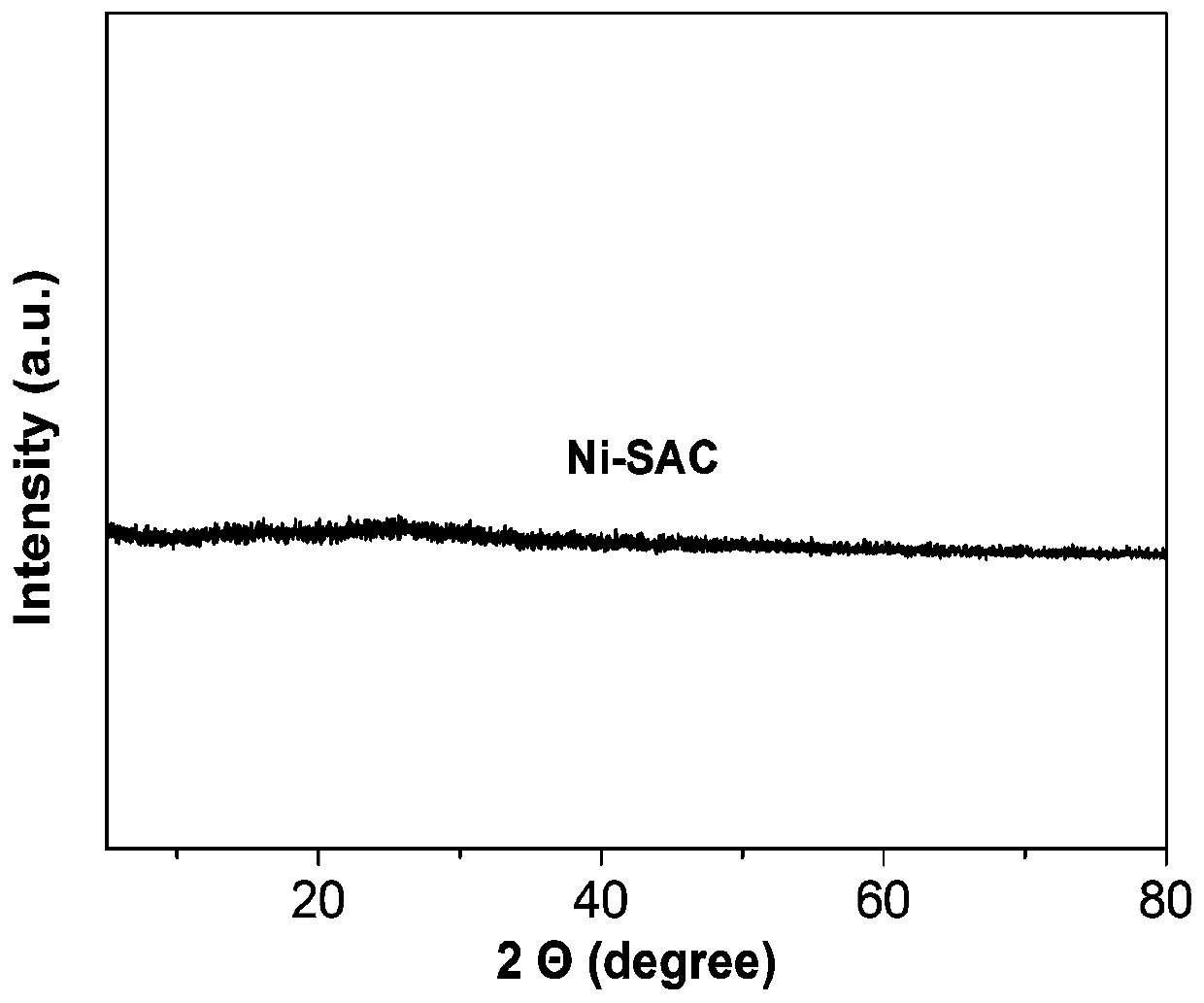

[0035] Preparation of Nickel Single Atoms

[0036] Add 40 mg of 1,3,5 trimesic acid, 200 mg of cobalt nitrate hexahydrate and 30 mg of 2-mercaptopyrimidine nickel to 150 ml of DMSO solution and ultrasonicate for 30 min at room temperature to fully dissolve the organic ligand and the metal salt. Stir well and transfer to the reaction kettle. Use an oven to heat the reaction at a constant temperature of 90° C. for 2 days. A porous organometallic framework structure loaded with bipyridyl iron was obtained. Subsequently, the solvent is removed by centrifugation, washing, and vacuum drying, and the precursor is pulverized into powder and placed in a porcelain boat. The sample was calcined and pyrolyzed in a tube furnace filled with inert gas. The heating rate is 2°C / min, and the temperature is controlled below 300°C for 2 hours. Through the above steps, a purple powder is finally obtained.

Embodiment 3

[0038] Preparation of Platinum Single Atoms

[0039]Add 40 mg of 1,3,5 trimesic acid, 200 mg of cobalt nitrate hexahydrate and 40 mg of porphyrin platinum to 150 ml of DMSO solution and sonicate for 30 min at room temperature to fully dissolve the organic ligand and the metal salt. Stir well and transfer to the reaction kettle. Use an oven to heat the reaction at a constant temperature of 90° C. for 2 days. A porous organometallic framework structure loaded with bipyridyl iron was obtained. Subsequently, the solvent is removed by centrifugation, washing, and vacuum drying, and the precursor is pulverized into powder and placed in a porcelain boat. The sample was calcined and pyrolyzed in a tube furnace filled with inert gas. The heating rate is 2°C / min, and the temperature is controlled below 300°C for 2 hours. Through the above steps, a purple powder is finally obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com