Skewer clamping device and smokeless automatic barbecue machine

A technology of clamping device and barbecue machine, which is applied in the direction of roasting device, roaster/barbecue grid, conveyor objects, etc., can solve the problems of low production capacity, oily smoke, and impossibility of popularization and application, etc., to reduce labor Labor force, reduction of oil fume generation, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

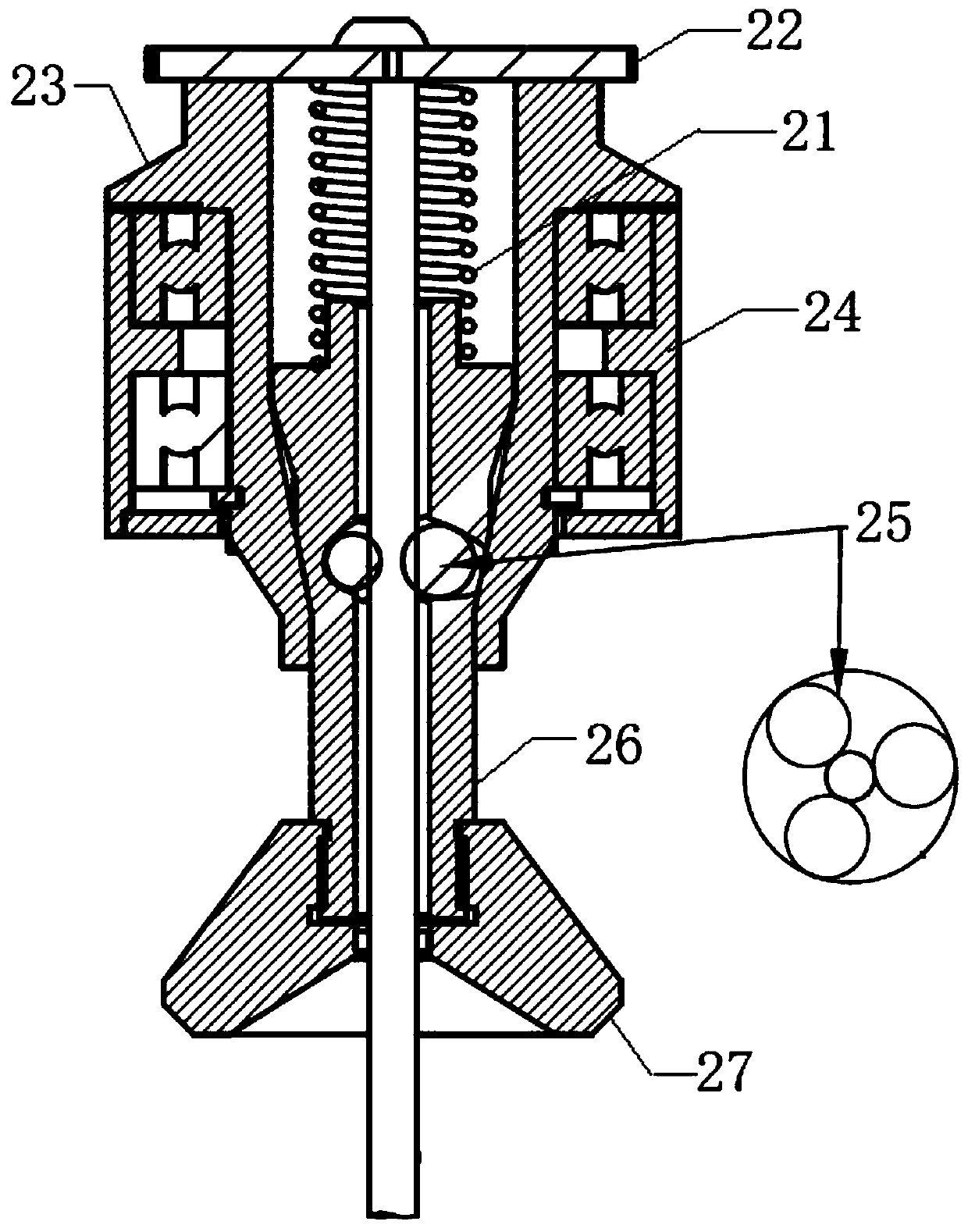

[0045] see figure 1 with Figure 4 , the present embodiment provides a stick holding device 2, comprising: a first transmission member 22, a rotating member 23, an elastic member 21, a fixing member 24 and a clamping member 26;

[0046] The fixing part 24 is sleeved on the rotating part 23 and is rotationally connected with the rotating part 23. One end of the rotating part 23 is fixedly connected with the first transmission part 22, and the other end of the rotating part 23 is provided with a mounting hole. The elastic part 21 and the clamping part One end of 26 is located in the installation hole, one end of the elastic member 21 is connected with the installation hole, the other end of the elastic member 21 is connected with the clamping member 26, the clamping member 26 slides along the direction of the installation hole, and the clamping member 26 slides along the direction of the installation hole. There are sign holes in the direction;

[0047] Wherein, the clamping m...

Embodiment 2

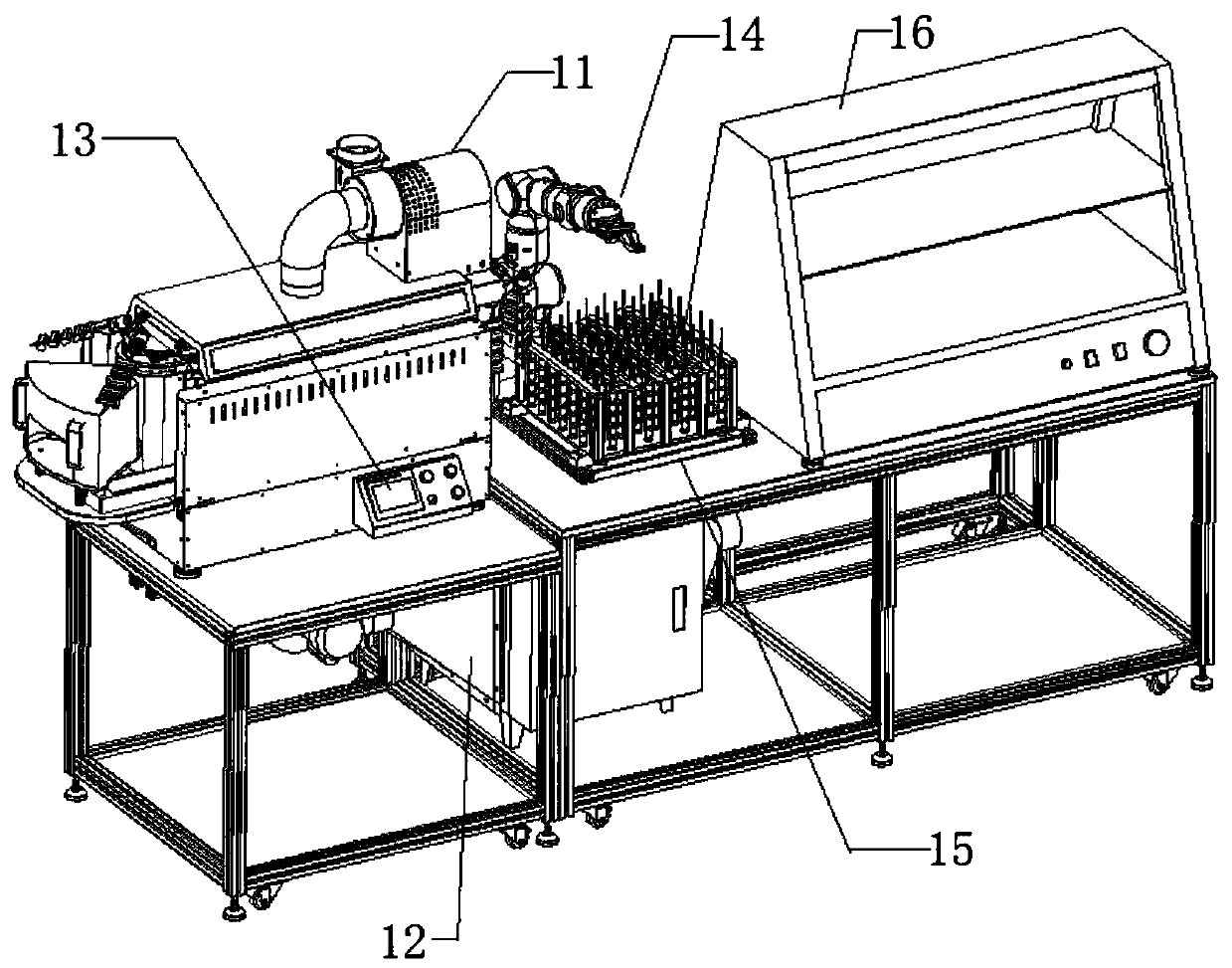

[0055] This embodiment provides a smokeless automatic barbecue machine based on Embodiment 1, which adopts the stick holding device 2 as in any one of Embodiment 1.

[0056] see figure 2 with Figure 4 , a smokeless automatic barbecue machine, comprising: a base 9, a furnace body 10, a heating part, a transmission mechanism 1 and a control part 13, and a grill stick holding device 2 of the above-mentioned structure; the furnace body 10 and the heating part are all located at On the base 9, the heating part is arranged on both sides of the furnace body 10, and a heating space is formed between the furnace body 10 and the heating part; part 17, the moving connecting part 17 is connected with the fixed part 24 of the baking stick holding device 2, and is used to drive the baking stick holding device 2 to move around the side of the furnace body 10; the control part 13 is electrically connected with the transmission mechanism 1 and the heating part respectively Wherein, the fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com