First-in first-out rod-shaped object storage device with variable volume

A first-in-first-out, storage device technology, applied in the field of tobacco processing, can solve the problems that plague the production of production enterprises, reduce the space occupied by the cache capacity, and occupy a large space, and achieve the reduction of storage capacity, increase of storage capacity, and flexible width adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

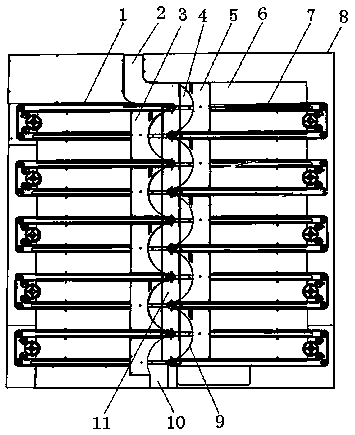

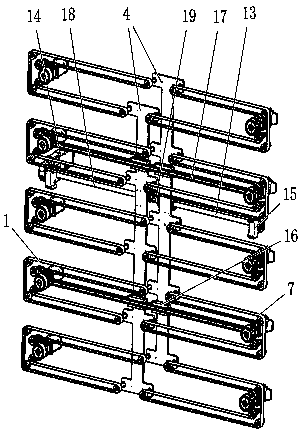

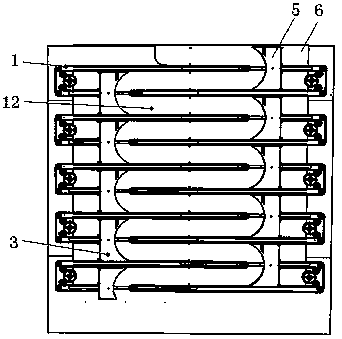

[0014] The present invention will be further described below with reference to the accompanying drawings.

[0015] The variable-volume, first-in, first-out rod storage device provided by the present invention includes a rectangular cylinder 6 with an inlet 2 and an outlet 10 thereon, a casing 8 is provided outside the rectangular cylinder 6, Ten layers of conveying channels, each two-layer conveying channel is composed of two symmetrical conveyor belts 1, 7, the head end and the head end, the tail end and the tail end of the two conveyor belts 1, 7 are arranged side by side, and the two conveyor belts 1, 7 are arranged side by side. In the belts 1 and 7, the head end of the conveyor belt 7 on the right side and the tail end of the conveyor belt 1 on the left side are respectively connected with the right and left blanking baffles 5 and 3 of the inner side with grooves 9 that move toward each other. , the grooves 9 on the inner side of the oppositely moving blanking baffles are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com