Processing technology of quick-frozen corn

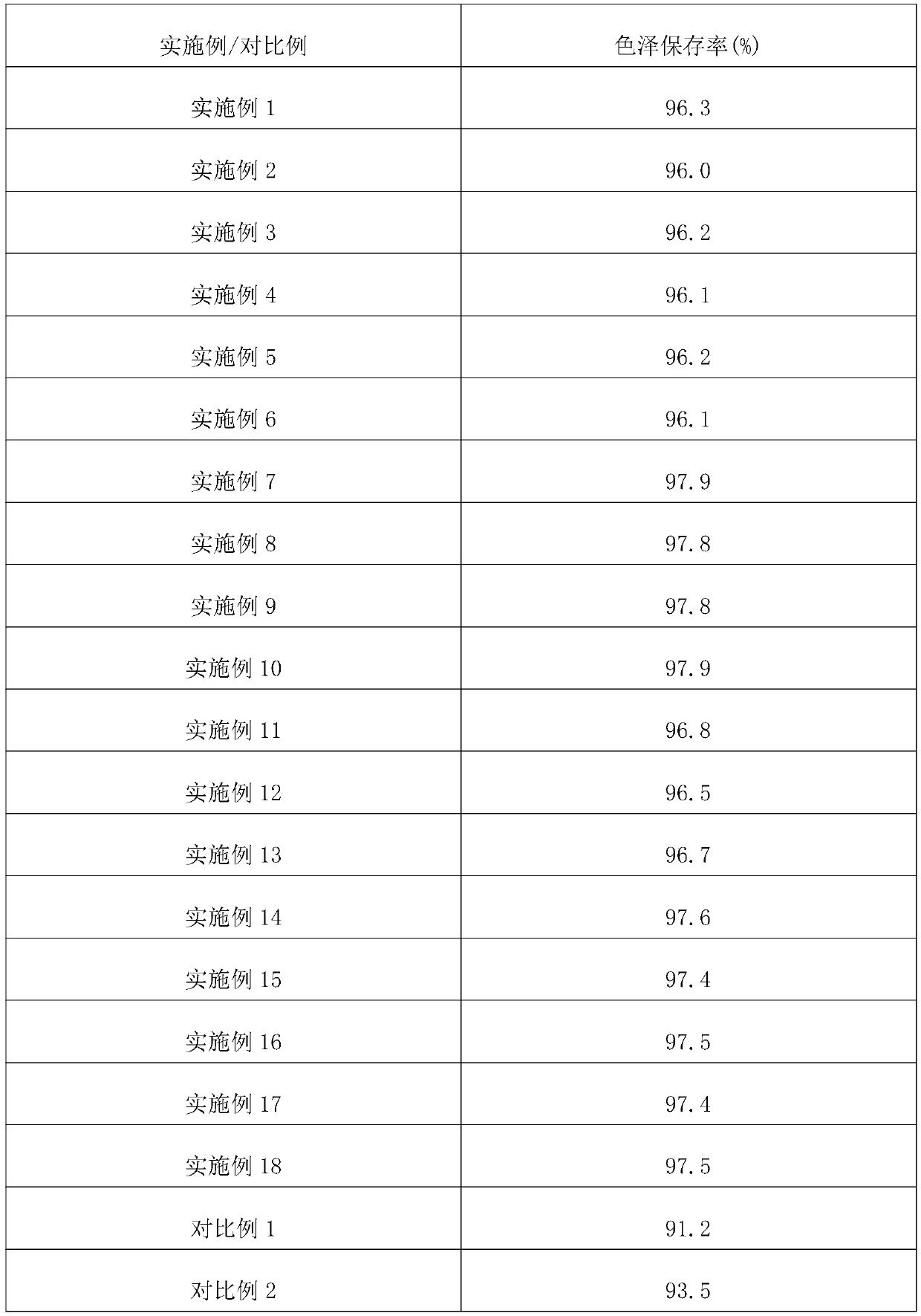

A processing technology, corn technology, applied in the function of food ingredients, preservation of seeds through freezing/cooling, food science, etc., can solve the problems of easy color change, lower color preservation rate, and lower quality of quick-frozen vegetables, etc., to achieve stability Good color, stable and excellent color, and the effect of preventing water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

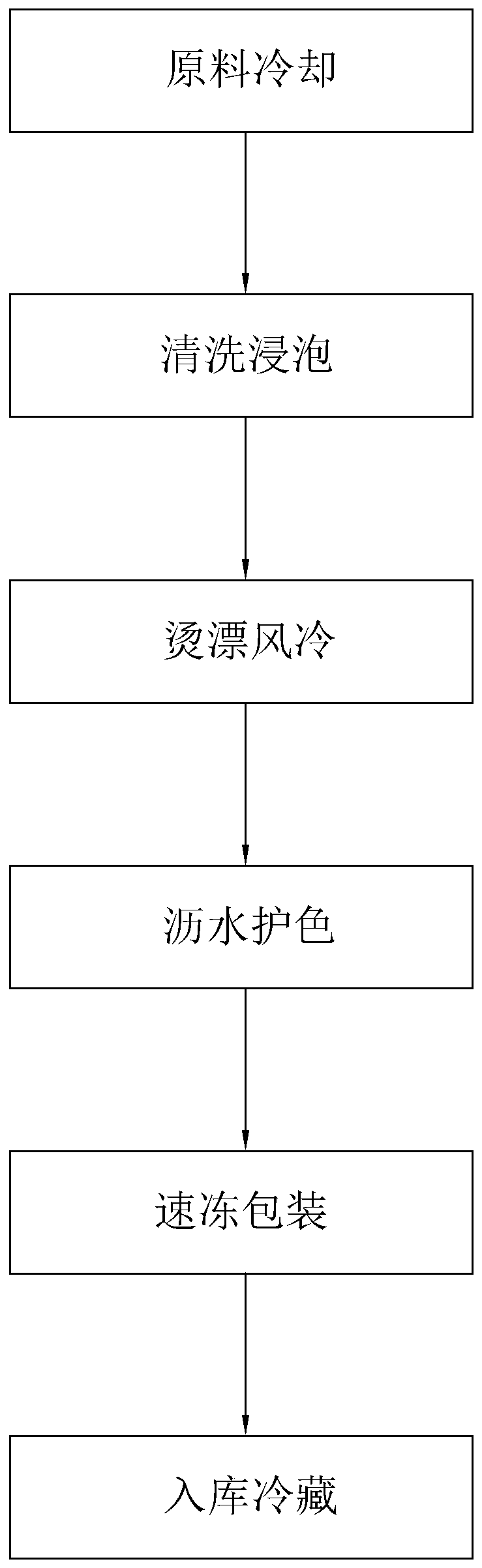

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: A kind of processing technology of quick-frozen corn, specifically prepares and obtains through the following steps:

[0043]Step 1, raw material cooling, select fresh corn material with no damage on the surface, put it into a vacuum freezer for cooling, the cooling temperature is -3.5°C, and the cooling time is 9 hours;

[0044] Step 2, cleaning and soaking, put the cooled corn material into the spiral cleaning equipment for cleaning, the cleaning time is 17.5 minutes, then take it out and soak in water with a salt content of 2.5% for 25 minutes;

[0045] Step 3, blanching and air cooling, blanching the washed and soaked corn material in the blanching equipment, the blanching temperature is 92.5°C, and the blanching time is 5 minutes, and then the blanched corn material is placed under the air cooler Carry out air cooling, and the air cooling time is 4 minutes;

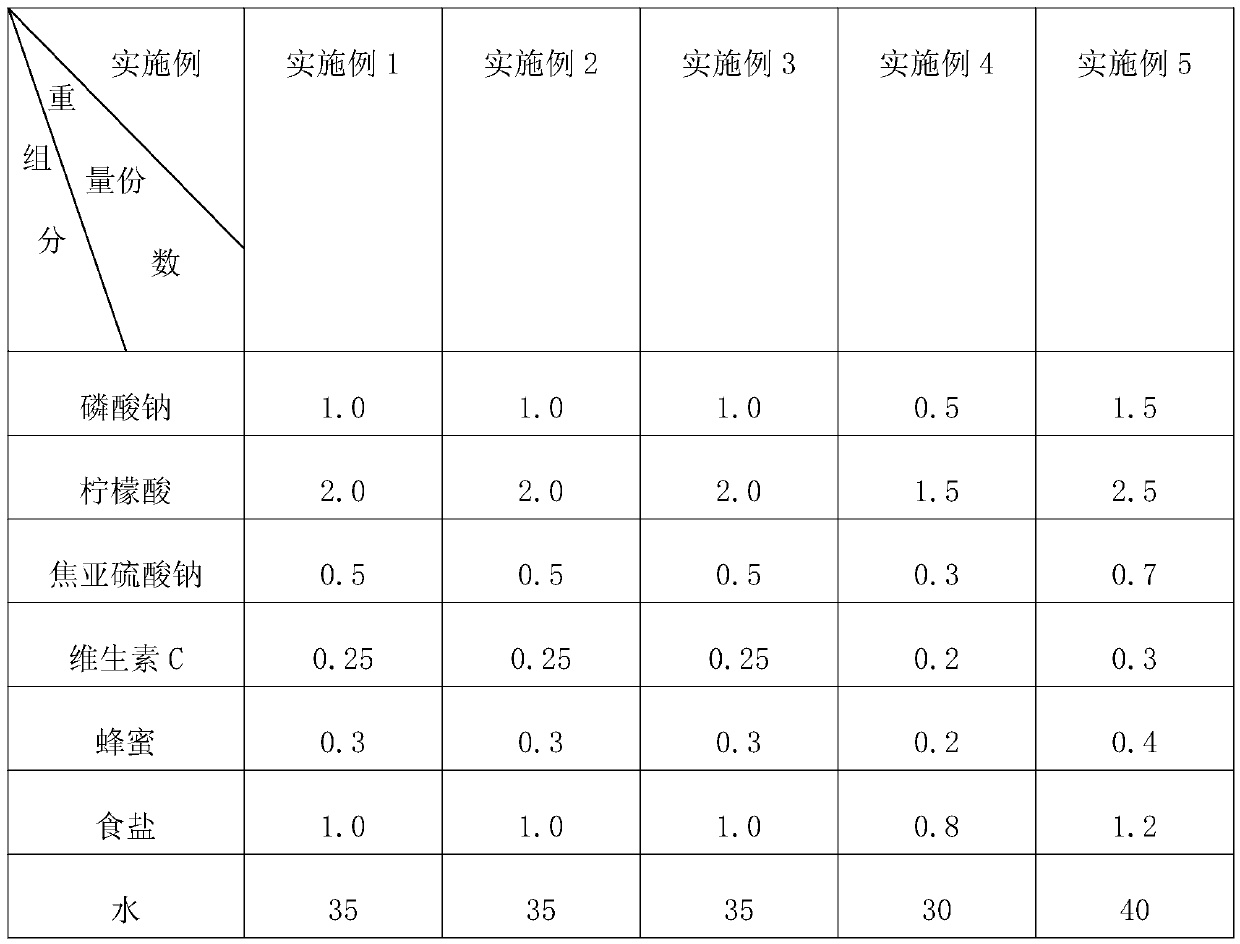

[0046] Step 4, Drain and protect the color, evenly spread the air-cooled corn material on th...

Embodiment 2

[0050] Embodiment 2: A processing technology of quick-frozen corn, the difference from Example 1 is that it is specifically prepared through the following steps:

[0051] Step 1, raw material cooling, select fresh corn material with no damage on the surface, put it into a vacuum freezer for cooling, the cooling temperature is -5°C, and the cooling time is 8 hours;

[0052] Step 2, cleaning and soaking, put the cooled corn material into the spiral cleaning equipment for cleaning, the cleaning time is 15 minutes, and then take it out and soak in water with a salt content of 3% for 20 minutes;

[0053] Step 3, blanching and air cooling, blanching the washed and soaked corn material in the blanching equipment, the blanching temperature is 90°C, and the blanching time is 6 minutes, and then the blanched corn material is placed under the air cooler Carry out air cooling, and the air cooling time is 3 minutes;

[0054] Step 4, Drain and protect the color, evenly spread the air-coole...

Embodiment 3

[0057] Embodiment 3: A processing technology of quick-frozen corn, the difference from Example 1 is that it is specifically prepared through the following steps:

[0058] Step 1, raw material cooling, select fresh corn material with no damage on the surface, put it into a vacuum freezer for cooling, the cooling temperature is -2°C, and the cooling time is 10 hours;

[0059] Step 2, cleaning and soaking, put the cooled corn material into the spiral cleaning equipment for cleaning, the cleaning time is 20 minutes, then take it out and soak in water with a salt content of 2% for 30 minutes;

[0060] Step 3, blanching and air cooling, blanching the washed and soaked corn material in the blanching equipment, the blanching temperature is 95°C, and the blanching time is 4 minutes, and then the blanched corn material is placed under the air cooler Carry out air cooling, and the air cooling time is 5 minutes;

[0061] Step 4, Drain and protect the color, evenly spread the air-cooled c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com